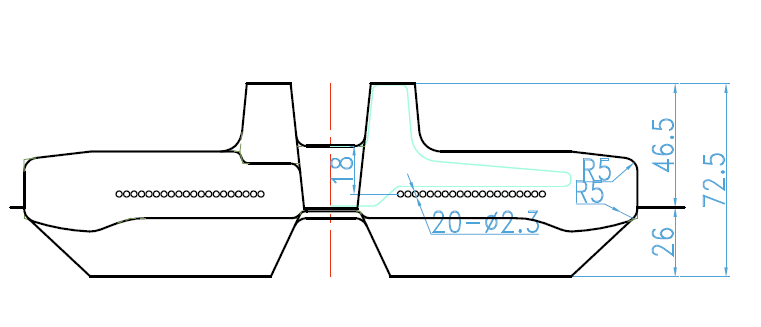

Rubber Tracks 240X87.6X28 Toro Dingo Tracks

240X87.6X28

ASV Tracks Warranty

ASV genuine OEM tracks are backed by the company’s industry-leading 2-year/2,000-hour warranty. The warranty covers tracks for the entire period and includes the industry’s first and only no-derailment guarantee on new machines.

ASV Tracks are Durable

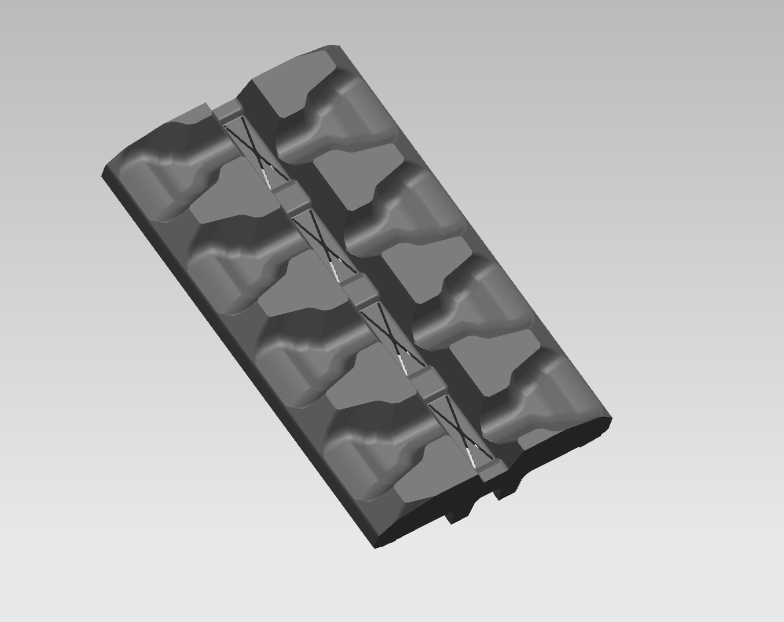

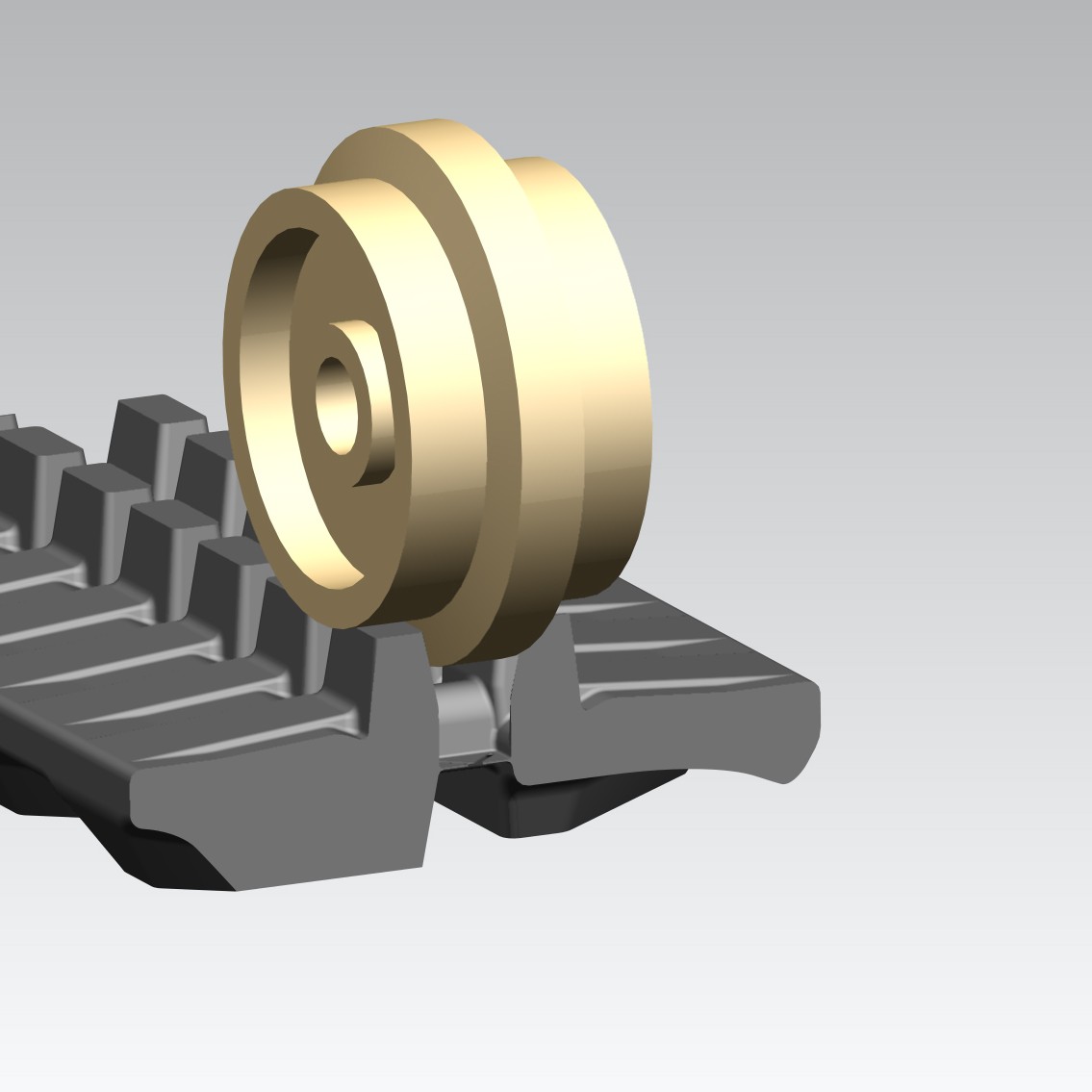

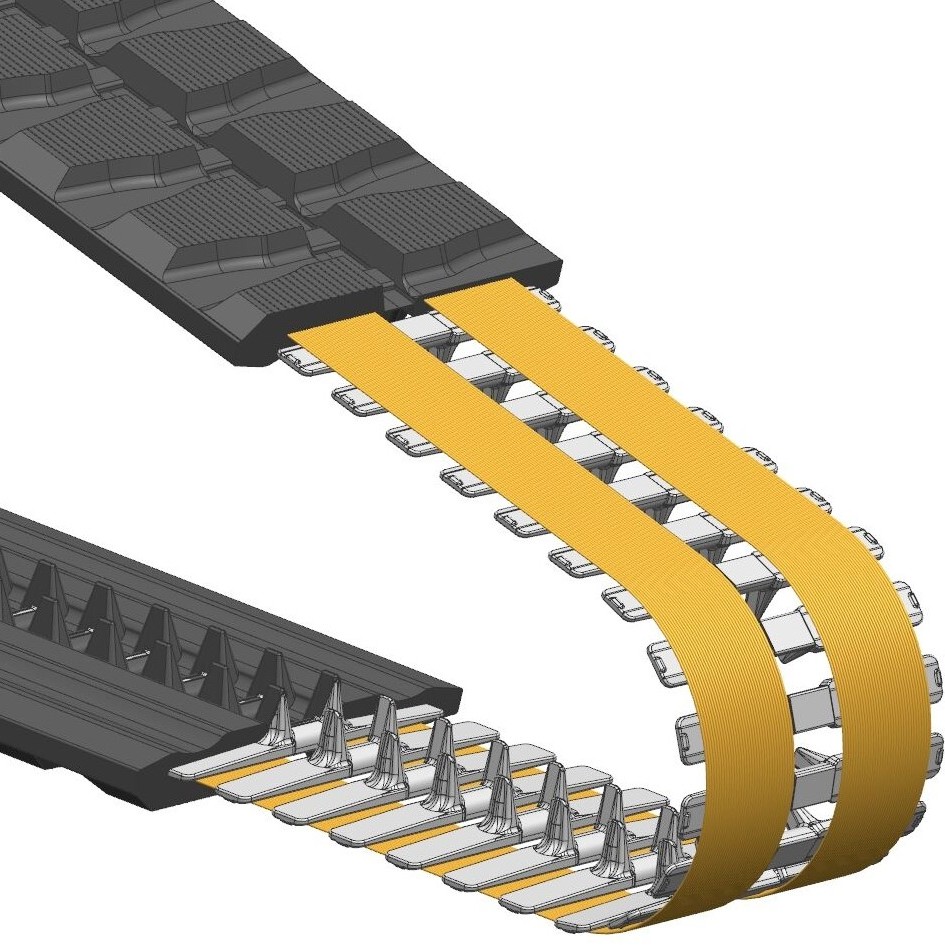

The rubber tracks eliminate rusting and corrosion because they contain no steel cords. Durability is maximized through seven layers of embedded puncture, cut and stretch resistant material. Additionally, the track’s flexible reinforcements are capable of bending around obstacles that may otherwise snap cords on a steel-embedded version or an aftermarket option with fewer layers of reinforcement and lower quality material.

ASV Tracks are Reliable

AVS rubber tracks also extend reliability and maximize resistance to wear and tear through a specialized blend of rubber compounds specifically designed for tracks used in industrial conditions. The tracks are highly consistent thanks to a single-cure process that eliminates the seams and weak points found in some aftermarket tracks. Pre-stretched for a consistent length with minimal stretching, the track minimizes wear due to a patented lug design, assuring maximum sprocket engagement.

Rubber Track Maintenance

(1) Always check the tightness of the track, in accordance with the requirements of the instruction manual, but tight, but loose.

(2) At any time to clear the track on the mud, wrapped grass, stones and foreign objects.

(3) Do not allow the oil to contaminate the track, especially when refueling or using oil to lubricate the drive chain. Take protective measures against the rubber track, such as covering the track with a plastic cloth.

(4) Ensure that the various auxiliary components in the crawler track are in normal operation and the wear is serious enough to be replaced in time. This is the basic condition for the normal operation of the crawler belt.

(5) When the crawler is stored for a long time, dirt and debris should be washed away and wiped, and the crawler should be stored overhead.

Q1: What advantages do you have?

A1. Good quality.

A2. Punctual delivery time. Normally 3 weeks for 1X20 container

A3. Smooth shipping. We have expert shipping department and forwarder, so we can promise faster delivery and make the goods well protected.

A4. Customers all over the world. Rich experience in foreign trade, we have customers all over the world.

A5. Active in reply.Our team will respond your request within 8-hour working time. For more questions and details, pls contact us by email or online.

Q2: What information should I offer to confirm a size?

A1. Track Width * Pitch Length * Links

A2. Your machine type (Like Bobcat E20)

A3. Quantity, FOB or CIF price,port

A4. If it is possible, pls also provide with pictures or drawing for double checking.