When I compare ASV rubber tracks to standard tracks, I notice significant differences in performance and durability. ASV rubber tracks provide superior traction and longevity. Choosing the right tracks is crucial for job site efficiency and safety. The right selection can enhance productivity and minimize risks.

Key Takeaways

- ASV rubber tracks provide superior traction and durability, enhancing job site efficiency and safety.

- Investing in ASV tracks leads to lower maintenance costs and fewer replacements, saving time and money in the long run.

- Operators experience improved comfort and stability with ASV tracks, reducing fatigue during long hours of operation.

Overview of ASV Rubber Tracks

Design Features

ASV tracks stand out due to their unique design features. I appreciate how these tracks incorporate innovative OEM designs that enhance traction and prevent derailment. Here are some key aspects that differentiate ASV rubber tracks from standard options:

- They utilize a specially formulated rubber compound that resists cutting and tearing.

- The design maximizes the amount of track on the ground, improving stability in various conditions.

- High-strength polyester wires integrated into the rubber structure minimize stretching and derailment.

- An all-terrain, all-season tread pattern ensures optimal performance across different weather conditions.

These features contribute to a longer track life and fewer replacements, which I find beneficial for maintaining job site efficiency.

Innovative Technology

ASV rubber tracks also incorporate advanced technologies that enhance their performance. The following table summarizes some of these innovations:

| Technology | Description |

|---|---|

| Posi-Track System | Helps machines move smoothly over rough ground and prevents them from getting stuck. |

| Independent Suspension | Designed for track operation, enhances smooth movement over rough terrain. |

| Guide Lug Surfaces | Prevents derailment, especially on slopes, improving stability. |

| Advanced Materials | Uses natural rubber for flexibility, reinforced with steel and Aramid string for durability. |

| Low Ground Pressure | Many wheel contact points and wide tracks provide industry-leading low ground pressures. |

| Patented Internal-Drive Sprockets | Maximizes power to attachments and reduces friction loss. |

| High-Strength Polyester Wires | Embedded within rubber to prevent stretching and ensure durability. |

| Rubber-on-Rubber Contact Design | Reduces wear on both the machine and tracks, ensuring smoother operation. |

These technologies not only improve traction and stability but also lead to lower repair costs and reduced fuel consumption. I find that ASV rubber tracks provide a smoother ride quality, which enhances overall user experience.

Overview of Standard Rubber Tracks

Common Characteristics

Standard rubber tracks are widely used in skid loaders due to their versatility and reliable performance. I find that these tracks strike a balance between durability and cost, making them suitable for operators who need dependable performance for general construction, landscaping, and agricultural tasks. Their design ensures compatibility with various skid loaders, providing consistent traction on flat or moderately uneven surfaces.

Typically, standard rubber tracks have a lifespan of 500 to 800 hours, which is adequate for lighter workloads. While they may not excel in extreme conditions, they serve as a reliable choice for everyday use. Here are some common characteristics I observe:

- Versatile Design: Compatible with multiple skid loader models.

- Reliable Traction: Performs well on flat and moderately uneven surfaces.

- Cost-Effective: Offers a good balance of durability and affordability.

Limitations in Performance

Despite their advantages, standard rubber tracks come with certain performance limitations. I have noticed that they often struggle in extreme weather conditions compared to ASV rubber tracks. For instance, while compact track loaders with snow tracks can enhance traction in snow, standard tracks may not perform as effectively.

Here’s a summary of some common performance limitations I’ve encountered:

| Performance Limitation | Description |

|---|---|

| Rolling Resistance | Higher than that of tires due to internal power losses within the track. |

| Internal Motion Resistance | Increased energy consumption due to internal components of the crawler. |

| Maneuverability | Limited compared to wheeled vehicles, affecting overall operational efficiency. |

Additionally, I’ve seen that neglecting maintenance can lead to failures. Common causes include improper tension, debris accumulation, and continuous turning on one side. These factors can significantly reduce the effectiveness of standard rubber tracks.

Performance Comparison of ASV Rubber Tracks

Traction Analysis

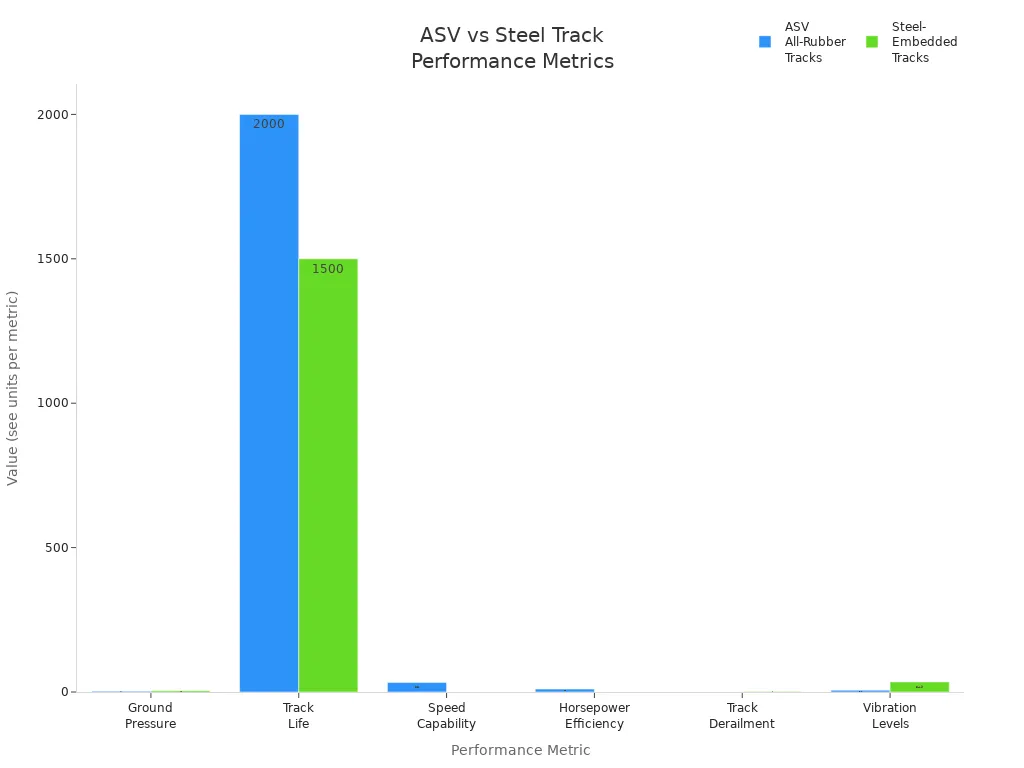

When I assess the traction capabilities of ASV rubber tracks, I find them to be exceptional compared to standard tracks. The unique design and materials used in ASV tracks provide superior grip on various surfaces. For instance, the ground pressure of ASV tracks is approximately 3.0 psi, significantly lower than the 4 to 5.5 psi of steel-embedded tracks. This lower ground pressure allows ASV tracks to excel in soft or muddy conditions without sinking.

Here’s a comparison of key performance metrics:

| Performance Metric | ASV All-Rubber Tracks | Steel-Embedded Tracks |

|---|---|---|

| Ground Pressure | ~3.0 psi | ~4 to 5.5 psi |

| Track Life (hours) | 1,500–2,000 (up to 5,000) | Shorter lifespan |

| Speed Capability | Up to 33% faster | Slower |

| Horsepower Efficiency | Up to 10% better | Lower |

| Track Derailment Frequency | Virtually none | Multiple derailments |

| Vibration Levels (G-force) | 6.4 Gs | 34.9 Gs |

From my experience, the ASV rubber tracks provide a smoother ride with less vibration, which enhances operator comfort and reduces fatigue during long hours of operation.

Durability Assessment

Durability is another area where ASV rubber tracks shine. The advanced materials used in their construction ensure they withstand harsh conditions better than standard tracks. I have observed that ASV tracks can last between 1,500 to 2,000 hours, with some even reaching up to 5,000 hours under optimal conditions. This longevity translates to fewer replacements and lower overall costs.

In contrast, standard tracks often have a shorter lifespan, which can lead to increased downtime and maintenance costs. The reinforced design of ASV tracks minimizes wear and tear, making them a more reliable choice for demanding job sites.

Adaptability to Job Site Conditions

ASV rubber tracks adapt remarkably well to various job site conditions. I have found that they excel in diverse terrains, including mud, snow, and gravel. The specialized tread patterns enhance grip and stability, allowing operators to navigate challenging environments with confidence.

Here’s a summary of the benefits of ASV tracks in different conditions:

| Feature | Benefit |

|---|---|

| Traction | Exceptional grip in challenging terrains like mud and snow. |

| Ground Pressure | Reduces ground pressure to prevent sinking in soft soil. |

| Weight Distribution | Distributes weight evenly across a large contact area for stability. |

| Tread Patterns | Specialized designs for different conditions (directional for mud, etc.) |

| Durability | Advanced materials ensure flexibility and longevity in various terrains. |

The Posi-Track system, which features more wheels per track, balances the load effectively and reduces ground pressure. This design allows ASV rubber tracks to perform optimally in various conditions, making them a versatile choice for any operator.

User Experiences with ASV Rubber Tracks

Testimonials from Operators

I have gathered numerous testimonials from operators who have switched to ASV rubber tracks. Their feedback highlights the significant improvements in handling and comfort. Here are some key insights:

- Operators have shared that they no longer worry about getting stuck in mud, indicating improved handling.

- One operator noted that the loader feels more stable on uneven terrain.

- Many users report feeling less fatigue after long shifts due to the reduced vibration in the cab.

The table below summarizes the specific features that operators appreciate:

| Feature | Evidence |

|---|---|

| Reduced Vibration | Operators experience less vibration in the cab, contributing to overall comfort. |

| Improved Stability | Users report feeling more stable on hills and rough ground, enhancing handling. |

| Operator Satisfaction | Overall operator satisfaction is noted, with reduced tiredness after long shifts. |

Case Studies from Real Job Sites

Real-world applications of ASV rubber tracks demonstrate their advantages over standard tracks. I have reviewed several case studies that showcase the performance of ASV tracks in various job environments. Here are some notable examples:

| Customer / Case Study | Warranty Duration | Key Outcomes |

|---|---|---|

| Urban Development Partners | 6-18 months | Track life up to 1,200+ hours, fewer replacements, 85% fewer repair calls |

| Davidson Family Farms | 6-18 months | 12 more working days, less fuel used, better performance in muddy fields |

| Greenscape Solutions | 6-18 months | Track life up to 1,800+ hours, no failures during jobs, better return on investment |

These case studies illustrate how ASV rubber tracks can lead to significant operational efficiencies. For instance, Urban Development Partners reported a remarkable reduction in repair calls, while Davidson Family Farms enjoyed extended working days due to improved performance in challenging conditions.

However, some users have faced challenges when transitioning from standard tracks to ASV rubber tracks. Common issues include:

- Bearings failing due to seal degradation, leading to grease loss and expensive repairs.

- One user mentioned replacing six wheel assemblies within 1,000 hours due to seal damage.

- Another user experienced similar problems with their assemblies at around 1,100 hours, resulting in a complete refitting of the track assemblies.

Despite these challenges, the overall consensus remains positive. Operators appreciate the enhanced performance and durability of ASV rubber tracks, making them a worthwhile investment for demanding job sites.

Cost-Benefit Analysis of ASV Rubber Tracks

Initial Investment vs Long-Term Value

When I evaluate the cost of ASV rubber tracks, I consider both the initial investment and the long-term value. The upfront price of ASV tracks may seem higher than standard options, but hidden costs can significantly impact total ownership expenses. For instance, premature track failures often lead to machine downtime, which results in lost productivity and revenue.

I view ASV tracks as a long-term investment due to their durability and comprehensive warranty. This warranty minimizes downtime and repair costs. While budget tracks may have lower initial costs, they can lead to higher downtime costs from premature failures. In contrast, premium aftermarket tracks, although initially more expensive, offer better durability and reduce the risk of damage to other parts. This ultimately lowers the total cost of ownership.

Maintenance and Replacement Costs

Maintenance and replacement costs are crucial factors in my decision-making process. According to manufacturer data, ASV rubber tracks typically last over 1,200 hours, requiring replacement only once a year. In comparison, traditional tracks often last between 500 to 800 hours, necessitating 2 to 3 replacements annually.

| Track Type | Lifespan (hours) | Replacement Frequency (per year) |

|---|---|---|

| ASV Rubber Tracks | Over 1,200 | Once yearly |

| Traditional Tracks | 500-800 | 2-3 times |

This data highlights the significant savings in maintenance and replacement costs when using ASV rubber tracks. Fewer replacements mean less downtime and more time spent on productive work. Overall, I find that the long-term value of ASV tracks far outweighs the initial investment.

In summary, ASV rubber tracks offer numerous advantages over standard tracks. I appreciate their enhanced safety features, operator comfort, and lower maintenance needs. Here are some key benefits:

- Safety: ROPS and FOPS rated cabs provide excellent protection.

- Comfort: Padded seats and HVAC systems enhance the operator experience.

- Maintenance: Ground-level access simplifies servicing.

I encourage you to consider ASV tracks for your next project. Their durability and performance can significantly improve job site efficiency.

FAQ

What are the main benefits of ASV rubber tracks?

ASV rubber tracks offer superior traction, durability, and adaptability, enhancing job site efficiency and reducing maintenance costs.

How long do ASV rubber tracks typically last?

I find that ASV rubber tracks can last between 1,500 to 2,000 hours, with some reaching up to 5,000 hours under optimal conditions.

Are ASV rubber tracks worth the investment?

Absolutely! The long-term savings on maintenance and replacements make ASV tracks a smart investment for demanding job sites.

Post time: Feb-03-2026