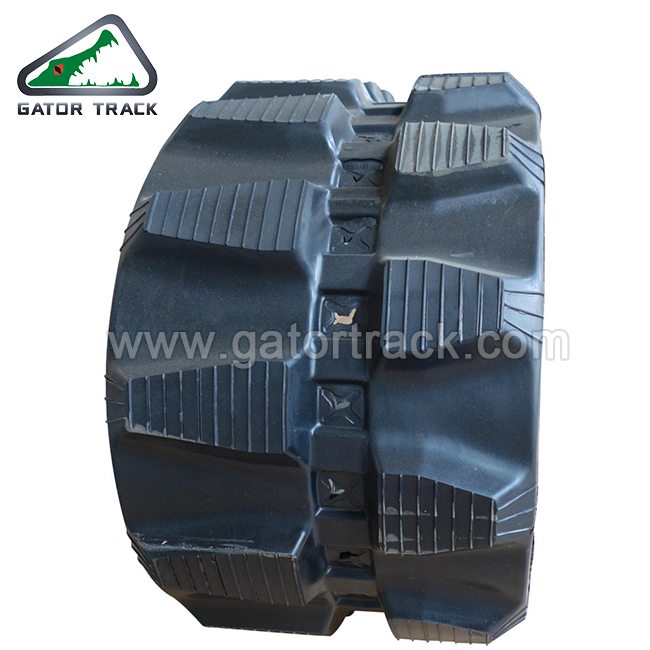

Rubber Track Tread Patterns from Leading China Manufacturers

When it comes to enhancing the performance of your machinery, the choice of rubber track tread patterns can make a huge difference. As a manufacturer in China, I understand the importance of selecting the right tread design to match the specific demands of various terrains. Our rubber tracks feature innovative tread patterns engineered for optimal traction, durability, and stability. With our extensive experience and commitment to quality, we cater to various industries, ensuring that your equipment operates smoothly and efficiently. Whether you're in construction, agriculture, or landscaping, our tracks are designed to withstand tough conditions while providing maximum grip. I know finding reliable suppliers can be tough, but choosing a trusted manufacturer like us means you're investing in excellence. Let's work together to elevate your operations with rubber tracks that truly deliver exceptional results.

Rubber Track Tread Patterns Application Factory

When it comes to choosing the right rubber track tread patterns for your machinery, understanding their specific applications can significantly enhance performance and durability. Different tread patterns are designed for varying terrains and operational requirements, making it crucial to select the appropriate type to optimize efficiency. For instance, aggressive tread patterns with deeper lugs are well-suited for rough and uneven terrain, providing excellent traction during challenging conditions, while shallower patterns excel in softer surfaces, reducing soil disruption and improving maneuverability. In the manufacturing of rubber tracks, the quality of materials and the precision of the tread design play a vital role in the overall performance of the track system. Advanced manufacturing processes ensure that each track is built to withstand extreme conditions and provide longevity, which translates to reduced downtime and maintenance costs for operators. Collaborating with an experienced manufacturer can provide access to a wide range of tread patterns tailored to meet the specific needs of various industries, from agriculture and construction to landscaping and mining. Understanding the features and benefits of different rubber track tread patterns empowers global buyers to make informed decisions that enhance their fleet's productivity. By choosing the right tracks designed for specific applications, operators can ensure optimal performance, safety, and efficiency, ultimately leading to better investment returns and smoother operations. Investing in high-quality rubber tracks not only supports sustainability efforts but also provides a competitive edge in today’s fast-paced market.

Rubber Track Tread Patterns Application Factory

| Tread Pattern | Application | Terrain Type | Width (mm) | Load Capacity (kg) |

|---|---|---|---|---|

| Chevron | Excavators | Soft Soil | 400 | 3500 |

| Square | Skid Steer Loaders | Asphalt | 300 | 2500 |

| Lug | Bulldozers | Rocky Terrain | 500 | 4000 |

| Diamond | Telehandlers | Mixed Terrain | 450 | 3200 |

| Paddle | Crawlers | Wet or Muddy | 550 | 4500 |

Related Products