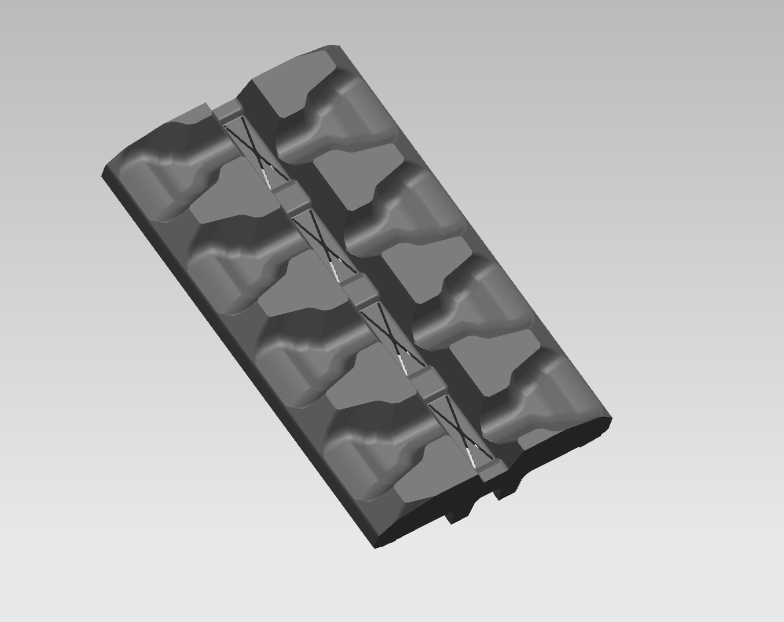

HXP400HK Excavator rubber track pads

Excavator track pads HXP400HK

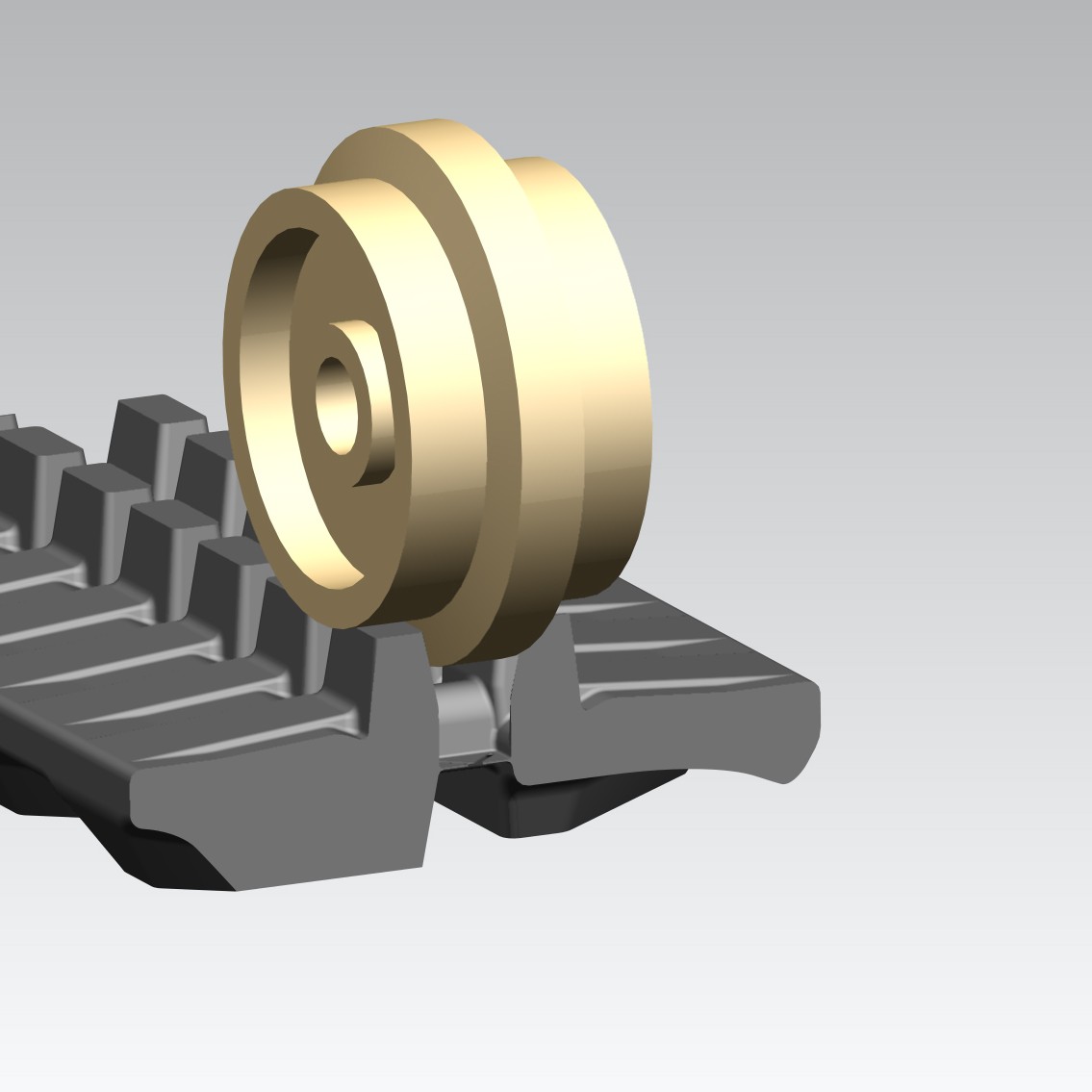

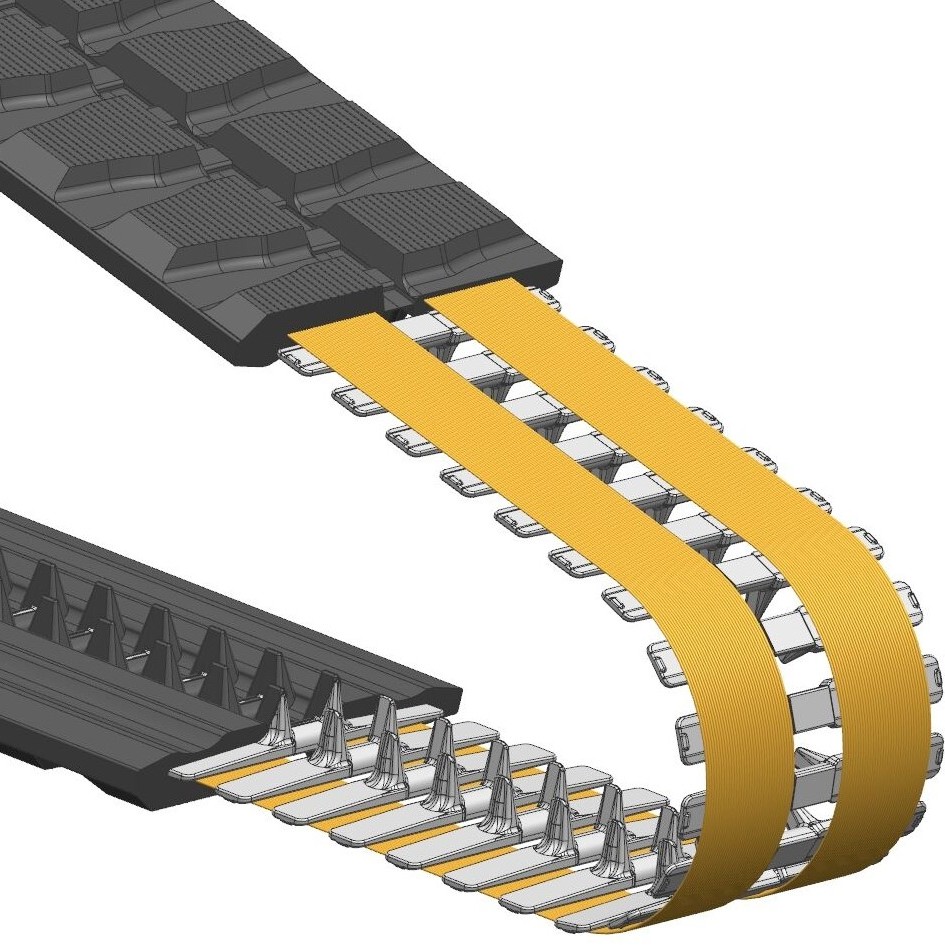

While the initial investment in clip on excavator track pads may be higher than steel alternatives, their long-term cost savings are substantial. Rubber pads excavator systems dramatically reduce undercarriage wear, extending the service life of rollers, idlers, and sprockets by up to 30%. Unlike metal digger track pads, rubber variants eliminate the need for frequent retensioning due to their flexibility. They also require no lubrication, cutting maintenance time and expenses. The lightweight nature of excavator pads reduces fuel consumption by decreasing the machine’s overall weight. Furthermore, their damage-free operation on paved surfaces avoids costly fines or repair bills from property owners. For fleet managers prioritizing total cost of ownership, excavator track pads made of rubber prove to be a financially savvy choice over time.

Sustainability-conscious companies increasingly prefer excavator rubber pads due to their eco-friendly advantages. Unlike steel digger track pads, rubber versions produce no sparks, making them safer for use near flammable materials. The noise reduction capabilities of rubber pads excavator contribute to lower environmental noise pollution, particularly in urban areas. Many modern excavator track pads incorporate recycled rubber materials without compromising performance. At end-of-life, these excavator pads can be recycled into new rubber products, unlike metal pads that often end up in landfills. Their non-marking operation preserves natural and man-made surfaces, reducing ecosystem disruption on sensitive job sites. For contractors seeking to meet green building standards or corporate sustainability goals, rubber-based excavator track pads offer clear ecological benefits.

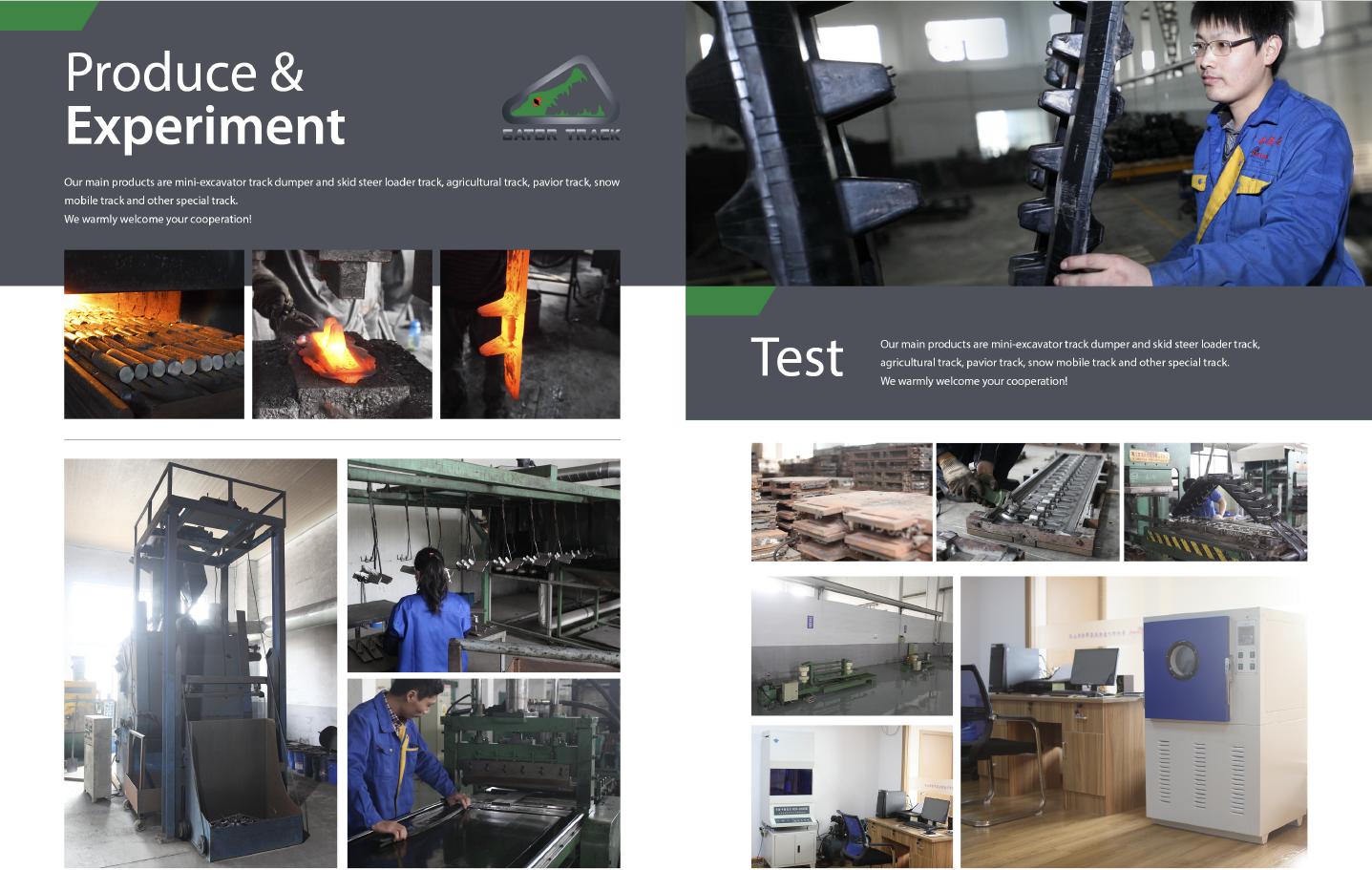

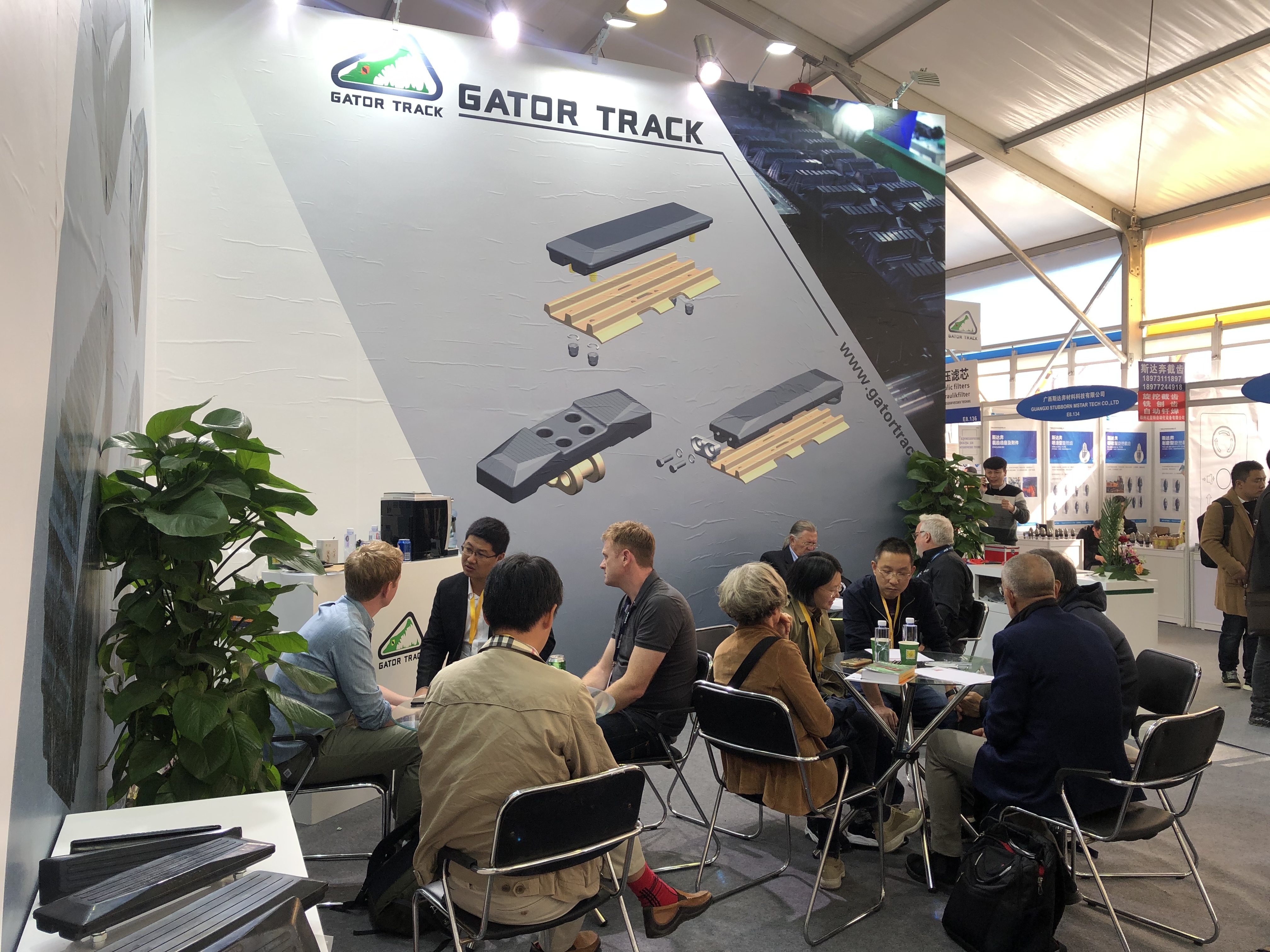

Founded in 2015, Gator Track Co., Ltd, is specialized in manufacturing rubber tracks and rubber pads. Production plant locates at No. 119 Houhuang, Wujin District, Changzhou, Jiangsu Province. We are happy to meet customers and friends from all parts of the world, it is always joyful to meet in person!

We currently have 10 vulcanization workers, 2 quality management personnel, 5 sales personnel, 3 management personnel, 3 technical personnel, and 5 warehouse management and container loading personnel.

Currently, our production capacity is 12-15 20 feet containers of rubber tracks per month. Annual turnover is US$7 million

1. What is your minimum order quantity?

We do not have a certain quantity requirement to start, any quantity is welcome!

2. How long is the delivery time?

30-45 days after order confirmation for 1X20 FCL.

3. Which port is closest to you?

We usually ship from Shanghai.