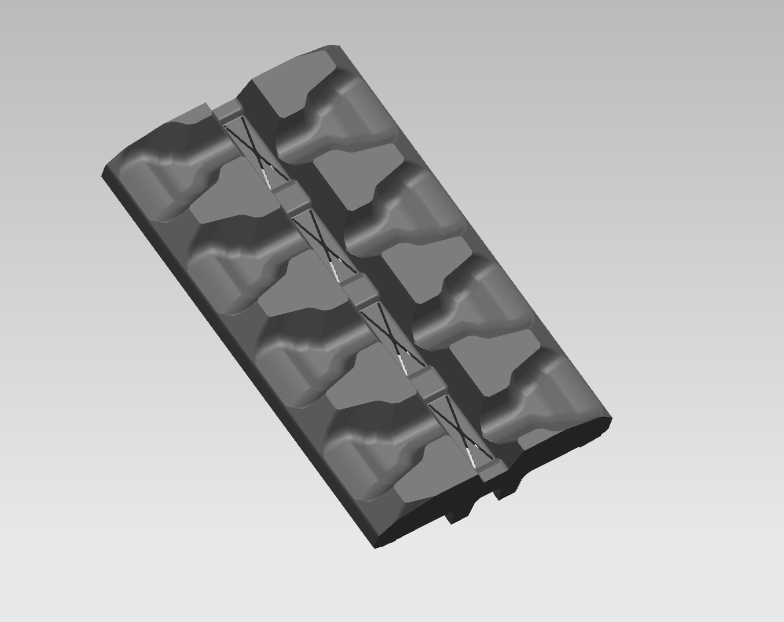

DRP600-216-CL Track pad excavator

Clip on excavator track pads DRP600-216-CL

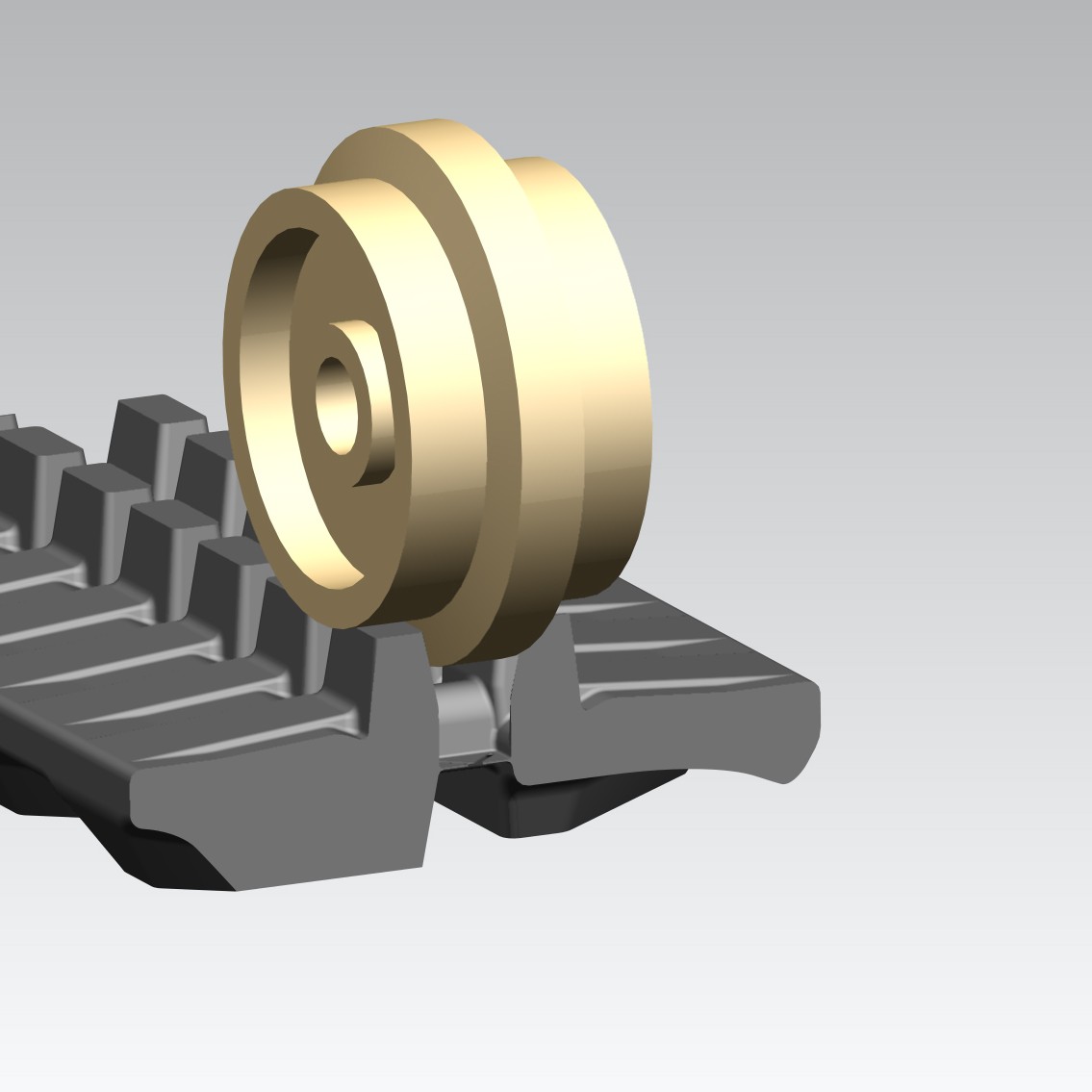

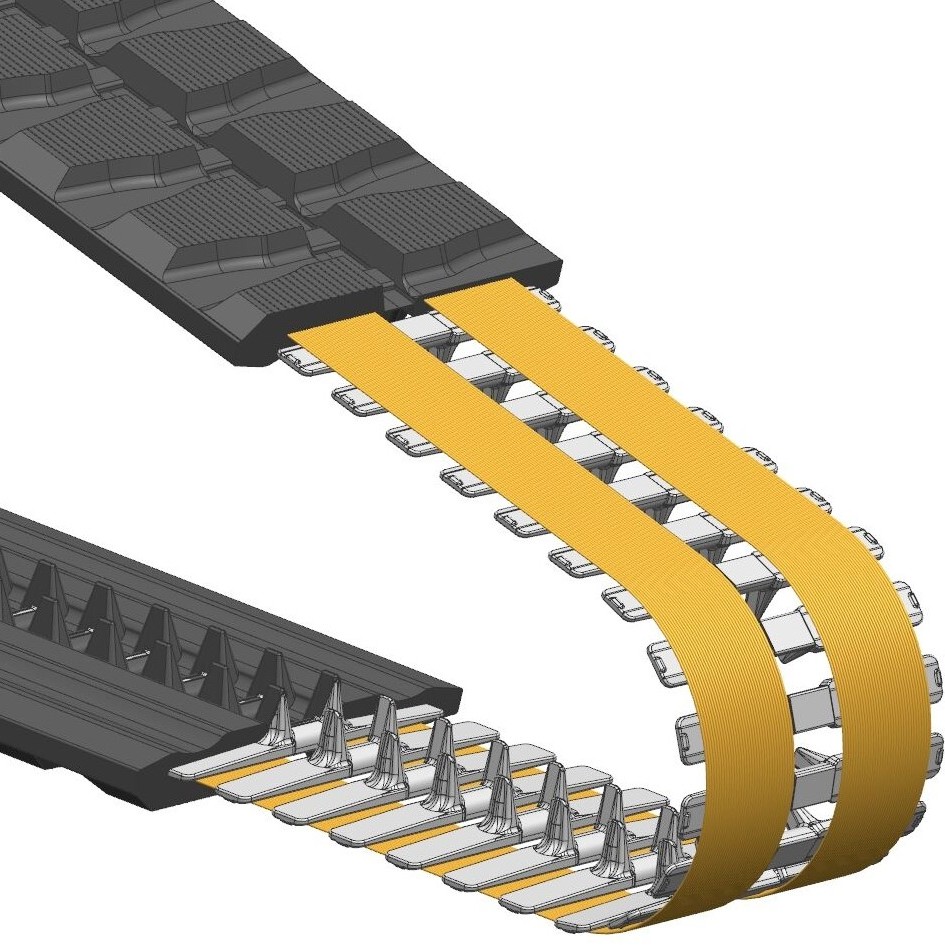

A major benefit of excavator rubber pads is their ability to significantly reduce noise and vibration compared to steel alternatives. Heavy machinery equipped with rubber pads excavator systems operates more quietly, which is crucial for urban construction sites with strict noise regulations. The rubber’s natural damping properties absorb vibrations, enhancing operator comfort and reducing fatigue during long shifts. This makes excavator track pads an excellent choice for projects near hospitals, schools, or residential areas. Additionally, the reduced vibration minimizes stress on the machine’s undercarriage, extending the lifespan of other components like rollers and sprockets. For contractors looking to improve workplace conditions and comply with environmental standards, excavator pads made from high-quality rubber are an optimal solution.

When working on delicate surfaces such as tarmac, pavements, or indoor flooring, excavator rubber pads prevent damage that would otherwise occur with steel tracks. The non-abrasive nature of rubber pads excavator ensures that finished surfaces remain intact, eliminating costly repairs or resurfacing. This makes excavator track pads ideal for municipal projects, event setups, and industrial facilities where floor protection is essential. Unlike metal digger track pads, rubber variants distribute weight more evenly, reducing ground pressure and preventing indentations. Many landscaping and utility companies prefer excavator pads for their ability to work on sensitive grounds without leaving marks or causing structural harm.

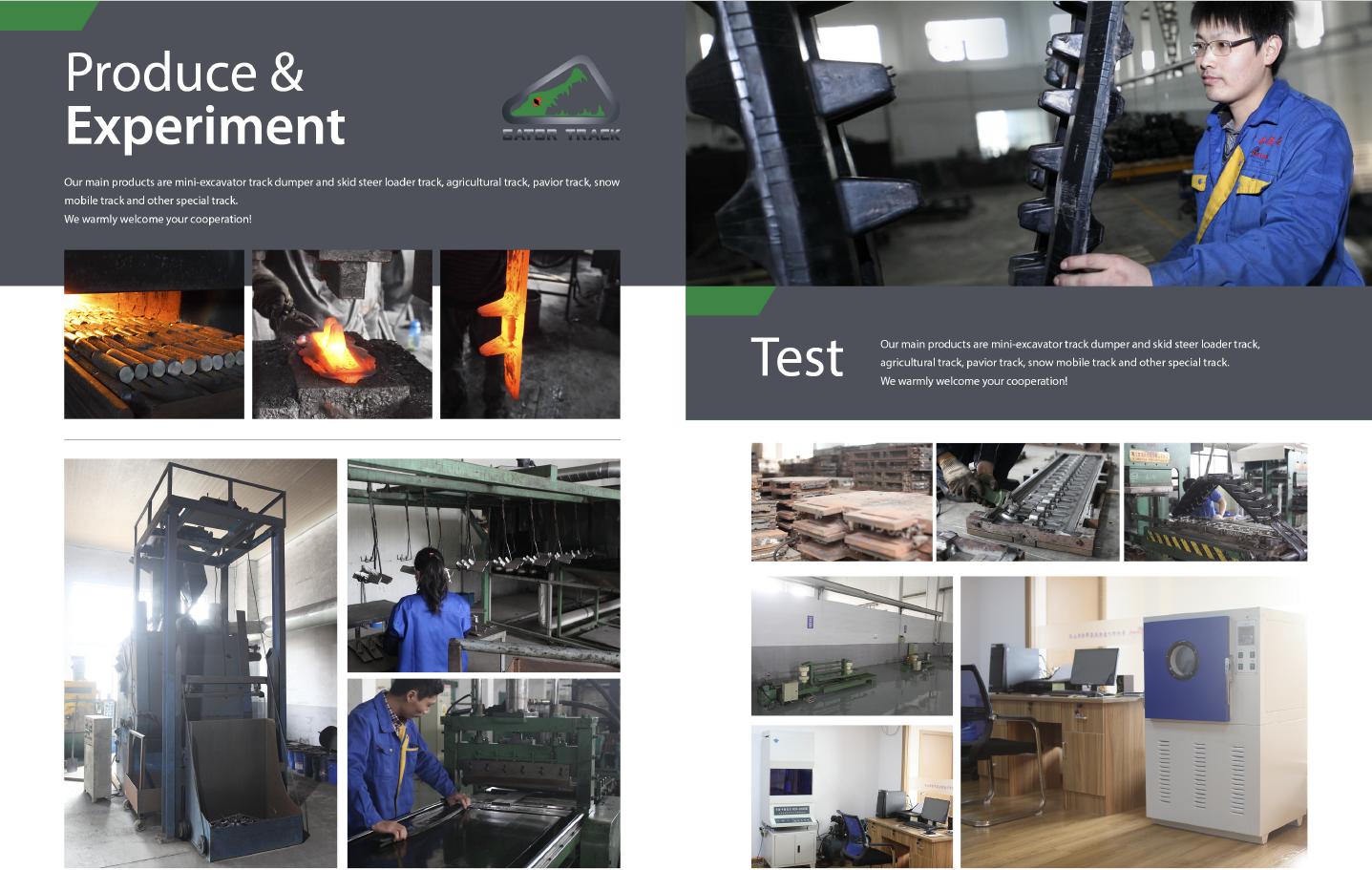

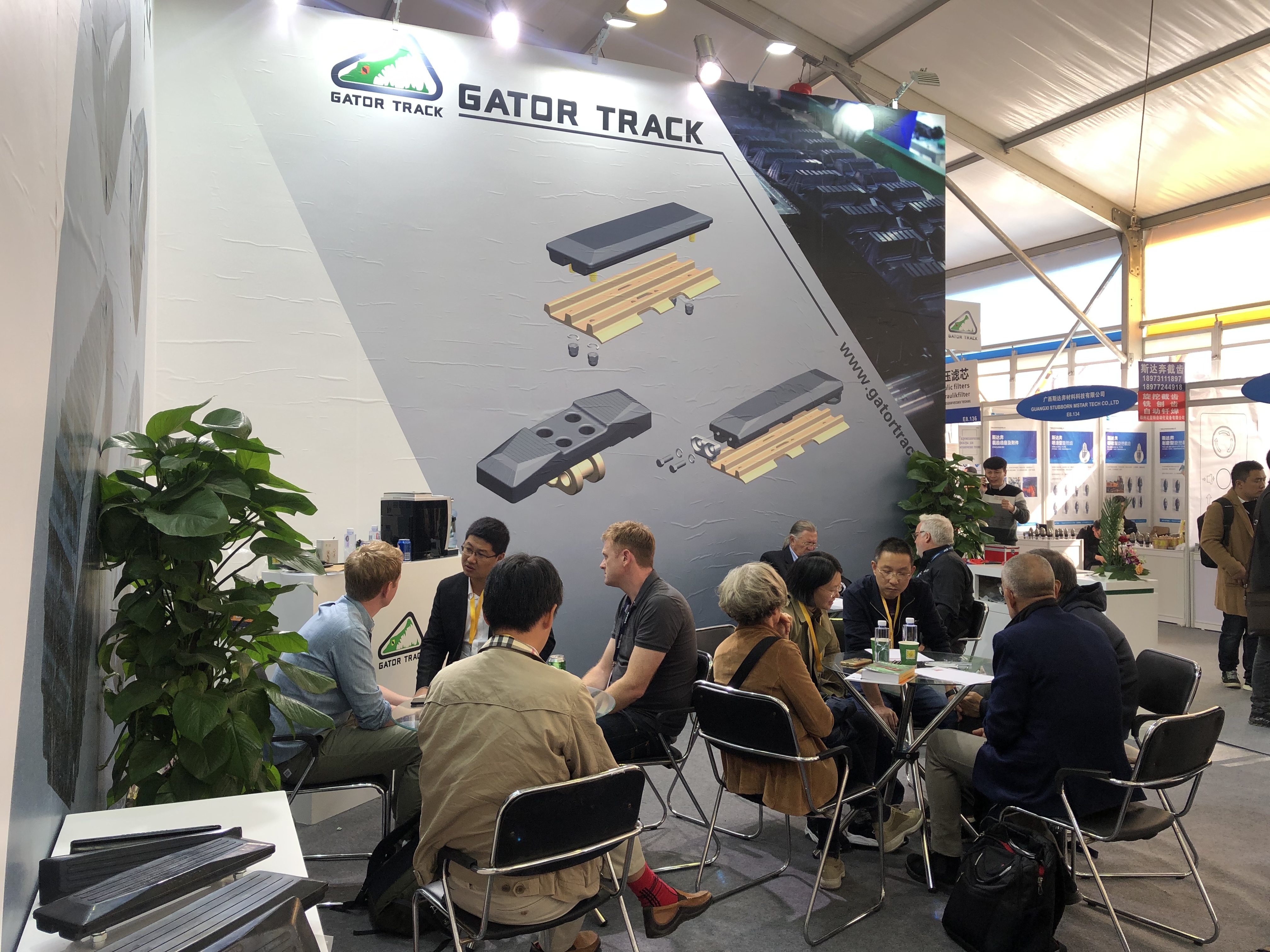

Founded in 2015, Gator Track Co., Ltd, is specialized in manufacturing rubber tracks and rubber pads. Production plant locates at No. 119 Houhuang, Wujin District, Changzhou, Jiangsu Province. We are happy to meet customers and friends from all parts of the world, it is always joyful to meet in person!

We currently have 10 vulcanization workers, 2 quality management personnel, 5 sales personnel, 3 management personnel, 3 technical personnel, and 5 warehouse management and container loading personnel.

Currently, our production capacity is 12-15 20 feet containers of rubber tracks per month. Annual turnover is US$7 million

1. What is your minimum order quantity?

We do not have a certain quantity requirement to start, any quantity is welcome!

2. What advantages do you have?

A1. Reliable quality,Resonable prices and quick aftersales service.

A2. Punctual delivery time. Normally 3 -4 weeks for 1X20 container

A3. Smooth shipping. We have expert shipping department and forwarder, so we can promise faster

delivery and make the goods well protected.

A4. Customers all over the world. Rich experience in foreign trade, we have customers all over the world.

A5. Active in reply.Our team will respond your request within 8-hour working time. For more questions

and details, pls contact us by email or WhatsApp.