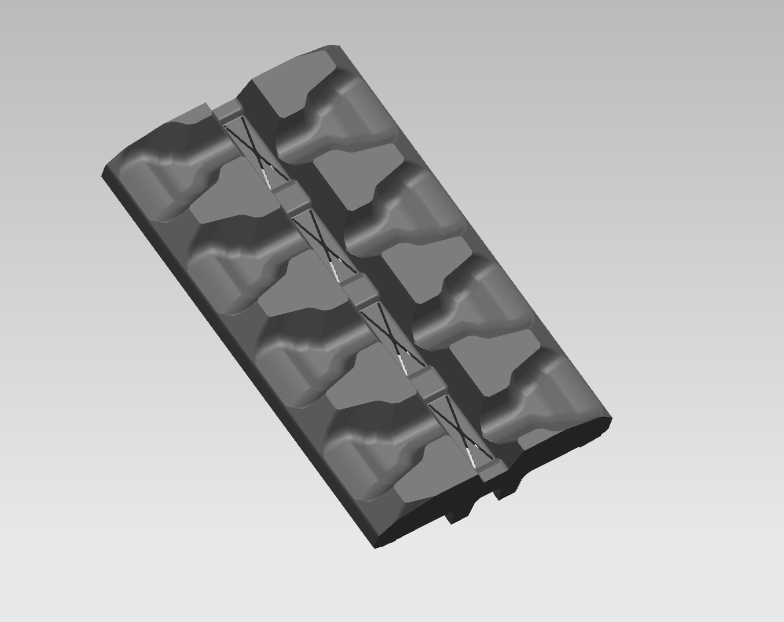

HXP300HD Track pad excavator

Excavator track pads HXP300HD

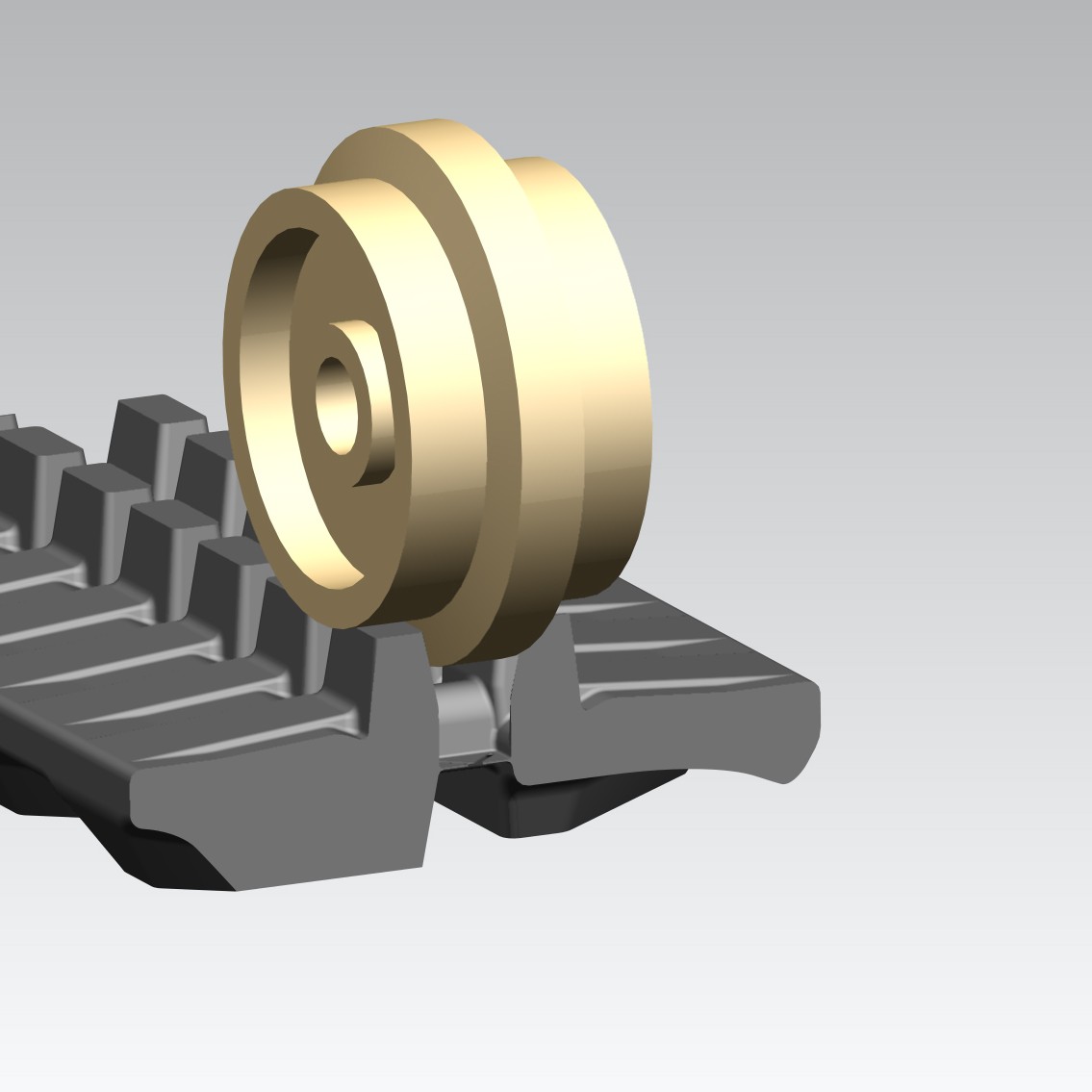

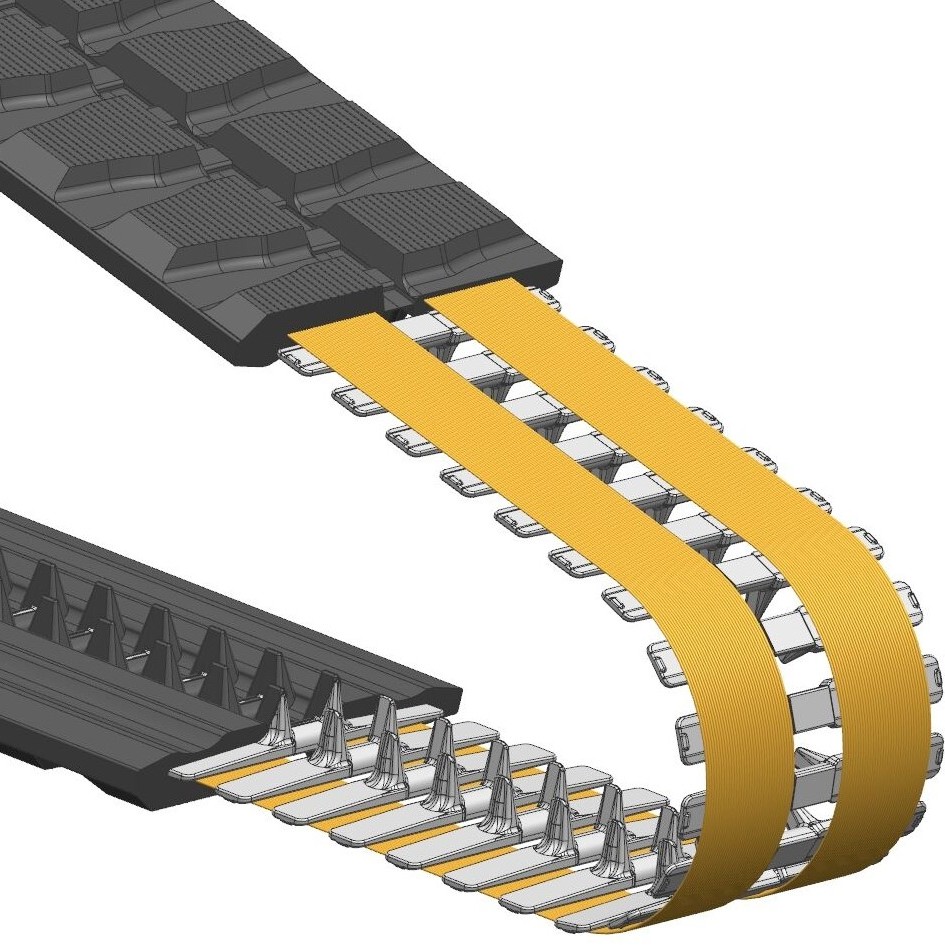

Installing excavator rubber pads is a straightforward process, compatible with most modern excavator models. These excavator track pads are designed with universal bolt patterns, allowing for quick replacement without requiring extensive modifications. Many rubber pads excavator systems feature interlocking mechanisms or pre-drilled holes for seamless attachment, reducing downtime during maintenance. Compared to steel digger track pads, rubber versions are lighter, making handling and installation easier for technicians. Additionally, their flexibility ensures a snug fit, minimizing the risk of detachment during operation. Whether replacing old pads or upgrading from metal tracks, excavator pads made from rubber offer a hassle-free installation process.

Excavator rubber pads are engineered to perform exceptionally well in diverse weather conditions, from freezing temperatures to scorching heat. Unlike steel digger track pads, which can become brittle in cold climates or slippery when wet, rubber pads excavator maintain consistent traction and flexibility. The advanced rubber compounds used in excavator track pads resist cracking in sub-zero environments while preventing overheating in high-temperature operations. This makes them ideal for year-round use in regions with extreme seasonal changes. Additionally, excavator pads provide superior mud-shedding capabilities, preventing clay and debris buildup that could impair mobility. For contractors working across multiple job sites with varying ground conditions, these excavator track pads deliver reliable performance regardless of weather challenges.

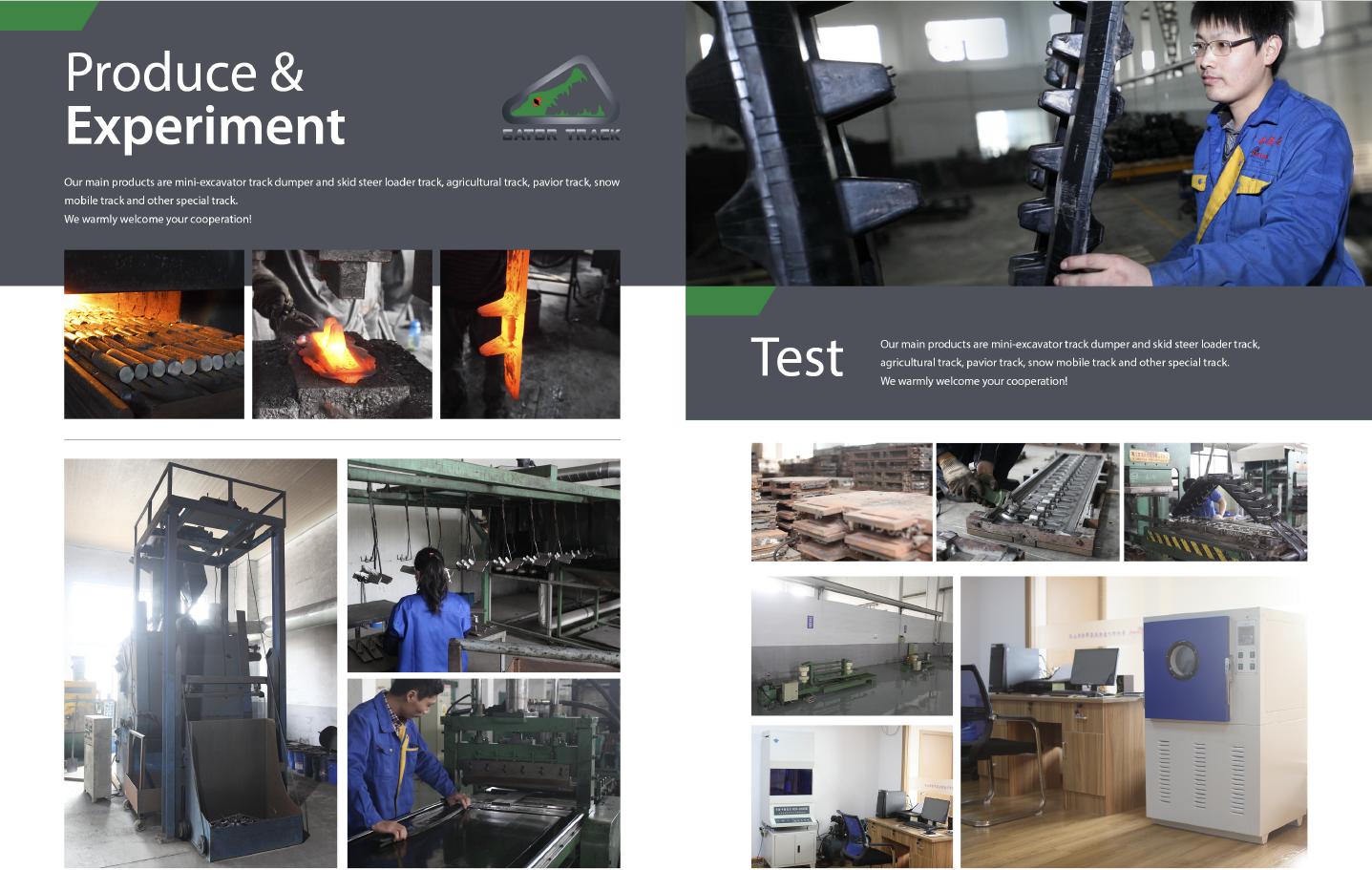

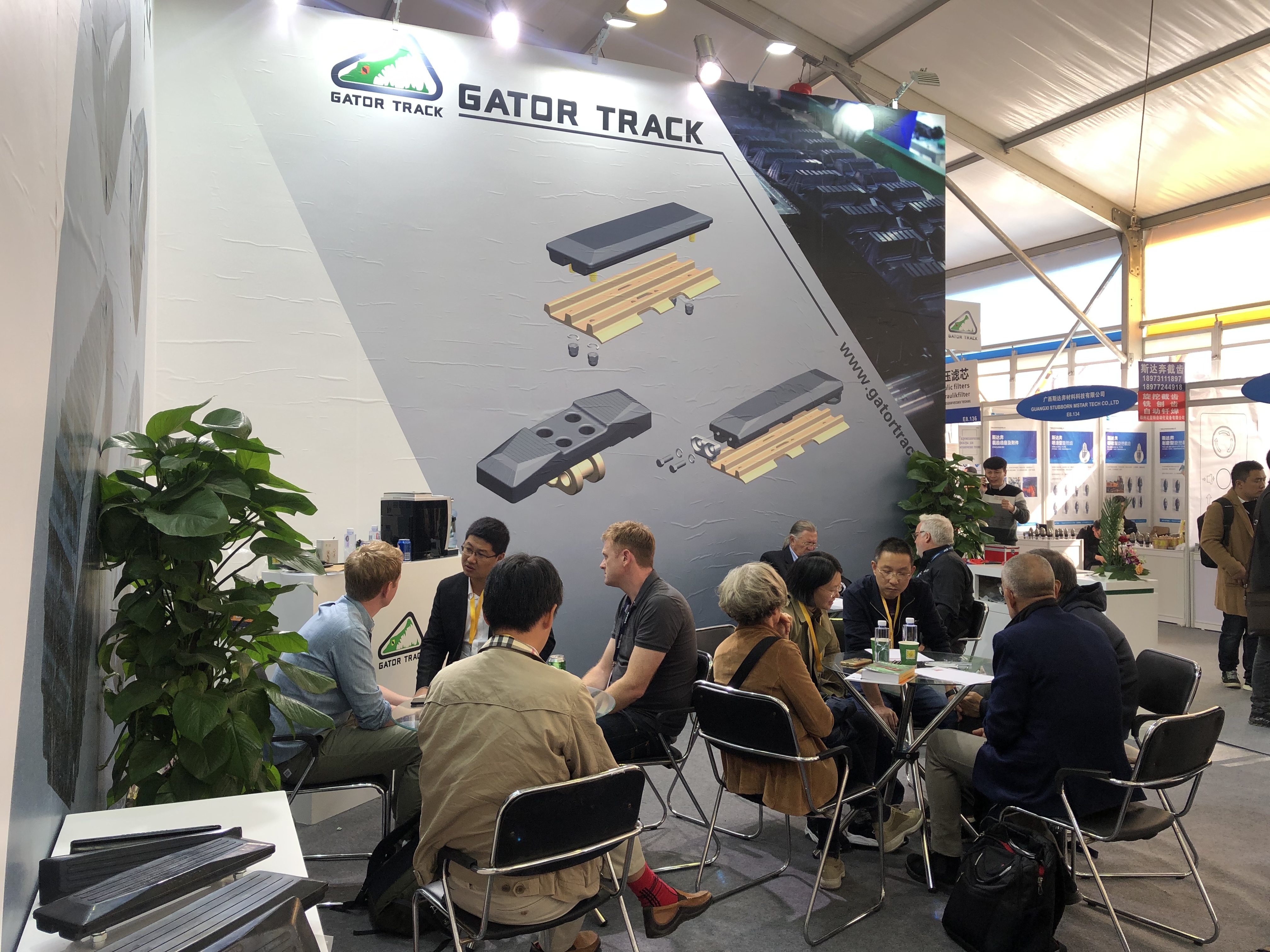

Founded in 2015, Gator Track Co., Ltd, is specialized in manufacturing rubber tracks and rubber pads. Production plant locates at No. 119 Houhuang, Wujin District, Changzhou, Jiangsu Province. We are happy to meet customers and friends from all parts of the world, it is always joyful to meet in person!

We currently have 10 vulcanization workers, 2 quality management personnel, 5 sales personnel, 3 management personnel, 3 technical personnel, and 5 warehouse management and container loading personnel.

Currently, our production capacity is 12-15 20 feet containers of rubber tracks per month. Annual turnover is US$7 million

1. What is your minimum order quantity?

We do not have a certain quantity requirement to start, any quantity is welcome!

2. How long is the delivery time?

30-45 days after order confirmation for 1X20 FCL.

3. Which port is closest to you?

We usually ship from Shanghai.

4. What advantages do you have?

A1. Reliable quality,Resonable prices and quick aftersales service.

A2. Punctual delivery time. Normally 3 -4 weeks for 1X20 container

A3. Smooth shipping. We have expert shipping department and forwarder, so we can promise faster

delivery and make the goods well protected.

A4. Customers all over the world. Rich experience in foreign trade, we have customers all over the world.

A5. Active in reply.Our team will respond your request within 8-hour working time. For more questions

and details, pls contact us by email or WhatsApp.