Selecting the right rubber tracks transforms machinery performance. Different designs, like dumper, ASV, and agricultural tracks, deliver unique benefits:

- Improved traction and stability boost safety and efficiency.

- High-quality tracks tailored to each machine reduce maintenance costs and extend equipment life.

- Proper sizing and fit prevent premature wear.

Key Takeaways

- Dumper, ASV, and agricultural rubber tracks each offer unique benefits that improve machine traction, stability, and efficiency in different terrains and industries.

- Choosing the right track size, tread pattern, and material for your machine and work environment helps extend track life, reduce maintenance costs, and protect soil and surfaces.

- Regular track inspection, cleaning, and proper tension adjustment are essential to maximize performance, prevent damage, and save money over time.

Rubber Tracks for Dumper Machinery

Dumper Track Definition

Dumper tracks are specialized rubber tracks designed for carrier dumpers and compact construction equipment. These tracks help machines move heavy loads over rough or uneven ground. Carrier dumpers, mini excavators, skid steers, and compact track loaders often use these tracks. They work well in construction sites, muddy fields, and other tough environments.

Design Features of Dumper Rubber Tracks

Manufacturers build dumper rubber tracks with strong rubber compounds and steel cable reinforcement. This design gives the tracks flexibility and durability. Many tracks have deep tread patterns for better grip on mud, snow, or gravel. Some models offer rotating beds for 360-degree unloading, making them even more versatile. Gator Track produces a wide range of dumper rubber tracks, using strict quality control and advanced technology to ensure long-lasting performance.

Strengths and Weaknesses of Dumper Tracks

Dumper tracks offer several strengths:

- Long lifespan and cost-effectiveness.

- Superior traction and stability on soft or uneven terrain.

- Smoother and quieter operation compared to steel tracks.

- Even weight distribution, which protects sensitive surfaces.

However, users should consider that rubber tracks can wear out over time and may require skilled technicians for maintenance. The initial purchase cost is higher than traditional wheels, but the benefits often outweigh this investment.

Best Applications for Dumper Rubber Tracks

Dumper rubber tracks shine in many industries:

- Construction sites for moving heavy materials.

- Mining, agriculture, and landscaping for handling tough terrain.

- Urban projects where reduced noise and ground damage matter.

These tracks provide better fuel efficiency, improved safety, and less soil compaction. Gator Track supplies high-quality dumper rubber tracks in various sizes and tread patterns, helping businesses boost productivity and protect their equipment investment.

Rubber Tracks for ASV Equipment

ASV Track Overview

ASV equipment stands out in the industry for its advanced undercarriage and drive systems. These machines require specialized rubber tracks to match their unique design. ASV’s Posi-Track system uses a patented undercarriage that maximizes ground contact and traction. Operators benefit from smoother rides, less vibration, and improved stability, even on soft or slippery terrain.

Unique Construction of ASV Rubber Tracks

ASV rubber tracks feature several innovative design elements:

- Fiber-reinforced industrial rubber compounds replace traditional steel cords, preventing rust and corrosion.

- Seven embedded layers resist punctures, cuts, and stretching.

- Flexible reinforcements allow the tracks to bend around obstacles without damage.

- An all-season bar-style tread pattern and specially formulated exterior tread maximize traction year-round.

- The single-cure manufacturing process eliminates seams and weak points, ensuring consistent performance.

These features make ASV tracks reliable and long-lasting, even in harsh industrial environments.

Performance of ASV Tracks

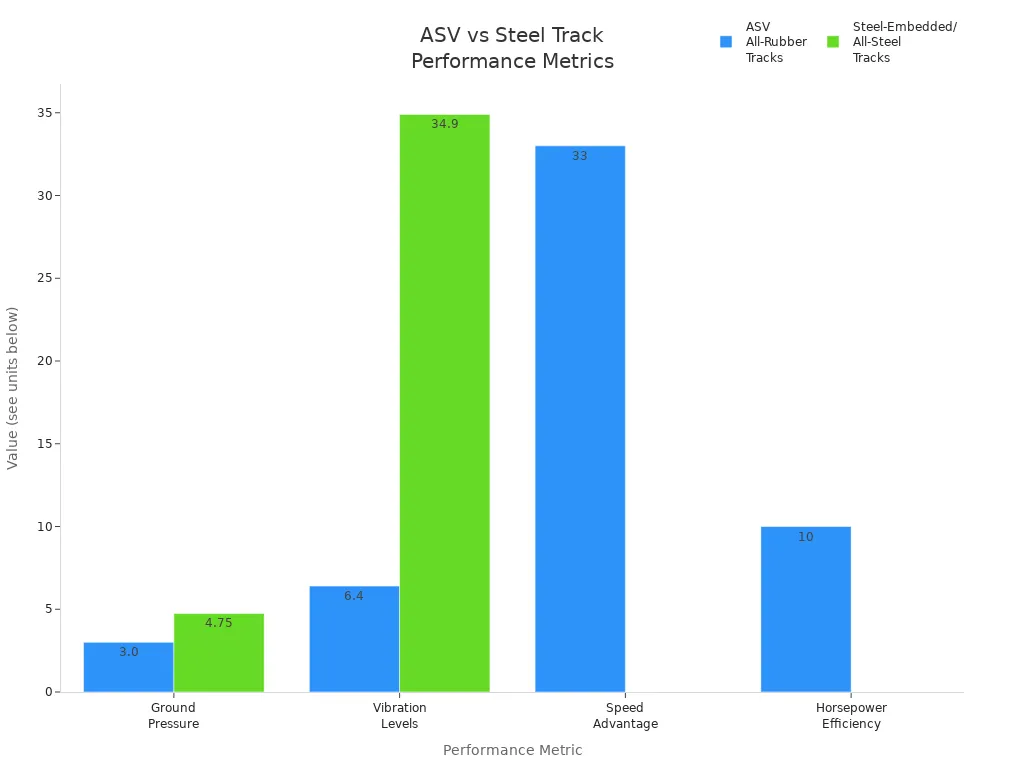

ASV tracks deliver impressive performance metrics compared to traditional steel-embedded tracks:

| Performance Metric | ASV All-Rubber Tracks | Steel-Embedded Tracks |

|---|---|---|

| Ground Pressure | ~3.0 psi | ~4 to 5.5 psi |

| Track Life (hours) | 1,500–2,000 (up to 5,000) | Shorter lifespan |

| Speed Capability | Up to 33% faster | Slower |

| Horsepower Efficiency | Up to 10% better | Lower |

| Track Derailment Frequency | Virtually none | Multiple derailments |

| Vibration Levels (G-force) | 6.4 Gs | 34.9 Gs |

Ideal Use Cases for ASV Rubber Tracks

ASV rubber tracks excel in several industries:

- Construction: Transition easily between debris-filled and finished surfaces.

- Agriculture: Minimize soil compaction and extend working seasons.

- Landscaping: Work on lawns and hardscapes without causing damage.

Operators enjoy enhanced traction, stability, and comfort. Gator Track offers high-quality ASV rubber tracks, helping businesses achieve top performance and reliability.

Rubber Tracks for Agricultural Machinery

Agricultural Track Definition

Agricultural tracks help tractors, harvesters, and other farm equipment move smoothly across fields. These tracks replace traditional tires, giving machines a larger surface area to touch the ground. Farmers use them to work in muddy, soft, or uneven fields where wheels might get stuck. Rubber tracks support heavy machinery and keep it stable during planting, tilling, and harvesting.

Key Design Elements of Agricultural Rubber Tracks

Modern agricultural tracks use advanced materials and smart engineering to boost performance.

- A larger ground contact area keeps machines from sinking in soft soil and improves stability.

- Special tread patterns grip muddy, steep, or wet ground, so equipment can work in tough conditions.

- Strong rubber compounds and steel cords resist cuts, stretching, and wear.

- Anti-corrosion treatments and weather-resistant features protect tracks from sun, rain, and chemicals.

- Vibration reduction and noise control make long days in the field more comfortable for operators.

- Custom options for width, tread, and undercarriage design help farmers match tracks to their land and crops.

Pros and Cons of Agricultural Tracks

| Advantage / Disadvantage | Description |

|---|---|

| Advantages | - Superior traction in wet soil |

- Zero-turn maneuverability

- No risk of flats

- Lower maintenance costs over time

- Versatility for many machines

- Reduced soil compaction and fuel use

- Improved stability and precision | | Disadvantages | – Higher upfront cost

- More moving parts to maintain

- Heavier weight can cause deep soil compaction

- Slower road speeds

- Limited adjustability

- Higher replacement cost

- Less effective in dry soil compared to some tires |

Note: Many farmers find that the long-term benefits of rubber tracks, such as better yields and lower maintenance, outweigh the initial investment.

Typical Uses for Agricultural Rubber Tracks

Farmers use rubber tracks on tractors, harvesters, and mini-excavators. These tracks help cover more acres, reduce fuel costs, and protect soil health.

- Tracked equipment can boost crop production by up to 25% compared to wheeled machines.

- Tracks allow for one-pass tillage, saving time and reducing soil disturbance.

- Machines with rubber tracks work longer in wet seasons, letting farmers plant and harvest on schedule.

- Lower soil compaction means better root growth and higher yields.

- Gator Track supplies durable agricultural tracks that help farmers increase productivity and reduce downtime.

Choosing the Right Rubber Tracks

Matching Tracks to Machinery Type

Selecting the correct tracks starts with matching them to the machinery. Each machine type—dumper, ASV, or agricultural—has unique requirements. Operators must check the machine’s model, size, and drive system. Tracks must fit the undercarriage exactly. A mismatch can cause early wear or even damage. The table below highlights important criteria for choosing between OEM and aftermarket tracks:

| Criteria | OEM Tracks | Aftermarket Tracks |

|---|---|---|

| Compatibility | Guaranteed fit for specific models | May vary; requires careful selection |

| Quality | High, strict standards | Variable; some premium options |

| Cost | Generally higher | Often more economical |

| Warranty | Usually included with machine | May be limited or separate |

| Application Options | Limited specialized designs | Greater variety and innovation |

Operators should always measure track width, pitch, and link count. Consulting the machine’s manual or a trusted supplier like Gator Track ensures the right fit. Gator Track offers a wide range of tracks for mini diggers, skid loaders, dumpers, and ASV equipment, helping customers find the perfect match for their machinery.

Evaluating Work Environment and Terrain

The work environment shapes the choice of tracks. Construction sites, muddy fields, rocky ground, and soft lawns all demand different features. Tracks spread the machine’s weight, giving better stability on soft or wet ground. This reduces the risk of sinking or losing balance. ASV tracks perform well on mud, snow, sand, and rocky surfaces. Their tread design and weight distribution help machines move safely and efficiently.

Operators should consider:

- Terrain type: Deep grooves for mud, block patterns for turf, and multi-bar treads for gravel.

- Machine weight: Heavier machines need reinforced tracks for durability.

- Ground disturbance: ASV tracks protect sensitive areas like lawns and wetlands.

- Weather resistance: Tracks must handle extreme heat, cold, or moisture.

Tip: Matching tread pattern and width to the terrain boosts traction and safety.

Considering Workload and Frequency

Workload and usage frequency affect track selection. Machines that run daily or carry heavy loads need tracks built for endurance. High-speed or high-frequency use increases vibration and motion resistance. This can lead to faster wear if the tracks are not designed for such stress. Operators should choose tracks with strong materials and reinforced edges for demanding jobs.

- Daily use: Pick tracks with high wear resistance.

- Occasional use: Standard tracks may be enough.

- Heavy loads: Wide tracks distribute weight and prevent sinking.

- High speeds: Tracks with low vibration and strong tension hold up better.

Gator Track’s products use advanced rubber compounds and strict quality checks, making them ideal for both light and heavy-duty applications.

Balancing Cost, Performance, and Maintenance

Operators must balance cost, performance, and maintenance when choosing tracks. High-quality tracks may cost more upfront but save money over time by lasting longer and reducing downtime. Regular inspections and proper care extend track life. The following best practices help maximize value:

- Select tracks that match OEM size and specifications.

- Choose tread patterns based on terrain and job needs.

- Inspect tracks daily for cuts, cracks, or debris.

- Adjust track tension regularly to prevent wear.

- Store equipment in dry, shaded areas to protect the rubber.

- Invest in premium tracks for harsh conditions.

- Schedule professional maintenance to avoid costly repairs.

Note: Ignoring small issues or skipping maintenance can lead to expensive breakdowns.

Gator Track provides reliable tracks and expert support, helping businesses achieve the best balance of cost, performance, and maintenance.

Choosing the right track boosts machine performance and saves money.

- Dumper tracks handle heavy loads on rough ground.

- ASV tracks give smooth rides and strong grip.

- Agricultural tracks protect soil and work well in wet fields.

Operators should check track fit, inspect parts, and follow expert care tips for best results.

FAQ

What makes Gator Track rubber tracks a smart investment?

Gator Track uses advanced materials and strict quality checks. Customers get longer-lasting tracks, less downtime, and better machine performance. Choose Gator Track for reliable results.

How do operators select the right track for their machine?

Operators should check the machine’s manual, measure track size, and consult experts. Gator Track’s team helps match tracks to any dumper, ASV, or agricultural equipment.

Can Gator Track rubber tracks handle extreme weather?

Yes! Gator Track designs tracks to resist heat, cold, and moisture. Operators can trust these tracks to perform in any season or climate.

Post time: Jul-29-2025