ASV tracks redefine ground performance in 2025 with cutting-edge features that boost efficiency. Their advanced design delivers longer track life, fewer replacements, and lower repair costs. Operators enjoy extended workable seasons, reduced fuel consumption, and unmatched traction. These tracks are durable, stable, and ready for any terrain, making them an essential upgrade for modern equipment.

Key Takeaways

- ASV tracks work better with new features, lasting longer and costing less to fix.

- The rubber-on-rubber design makes rides smoother and reduces damage, helping workers stay comfortable longer.

- The Posi-Track system spreads weight evenly, improving balance and grip on any surface, perfect for tough jobs.

Technological Advancements in ASV Tracks

Rubber-on-Rubber Contact for Improved Ride Quality

ASV tracks use a unique rubber-on-rubber contact design that transforms ride quality. This innovative feature reduces wear on both the machine and the tracks, ensuring smoother operation. The suspended frame complements this design by absorbing shocks and vibrations, making the ride more comfortable for operators.

Tip: The rubber-on-rubber contact minimizes stress on the equipment, extending its lifespan and reducing maintenance costs.

This advancement doesn’t just improve comfort—it boosts efficiency. Operators can work longer hours without fatigue, and the equipment performs reliably across uneven terrain. Whether it’s construction sites or agricultural fields, ASV tracks deliver consistent results.

High-Strength Polyester Wires for Durability

Durability is a cornerstone of ASV tracks, thanks to their high-strength polyester wires embedded within the rubber structure. These wires prevent track stretching and derailment, ensuring the tracks stay firmly in place

. Unlike steel, polyester wires resist cracking from repeated bending, making them lighter and rust-free.

The adaptable ropes allow the tracks to conform to the terrain’s contours, enhancing traction and stability. This design ensures that ASV tracks can handle all-season, all-terrain conditions without compromising performance.

| Metric | Before ASV Tracks | After ASV Tracks | Improvement |

|---|---|---|---|

| Average Track Life | 500 hours | 1,200 hours | Increased by 140% |

| Annual Replacement Frequency | 2-3 times/year | 1 time/year | Decreased by 67%-50% |

| Emergency Repair Calls | N/A | 85% decrease | Significant reduction |

| Total Track-Related Expenses | N/A | 32% decrease | Cost savings |

| Workable Season Extension | N/A | 12 days | Extended operational time |

| Fuel Consumption Reduction | N/A | 8% decrease | Efficiency gain |

These metrics highlight the durability and cost-effectiveness of ASV tracks, making them a smart investment for operators across industries.

Posi-Track System for Enhanced Stability and Traction

The Posi-Track system is a game-changer for stability and traction. It distributes weight evenly across the tracks, reducing ground pressure and improving flotation. This system ensures that ASV tracks maintain grip on slippery or uneven surfaces, making them ideal for challenging terrains.

Field tests on steep slopes revealed impressive results. The traction force kept bending stress and wheel-rail forces well within allowable limits, confirming the system’s reliability. Operators benefit from improved ground clearance and stability, enabling them to tackle tasks with confidence.

ASV tracks equipped with the Posi-Track system excel in all weather conditions. Whether it’s mud, snow, or gravel, these tracks deliver unmatched performance, ensuring uninterrupted operations year-round.

Practical Benefits of ASV Tracks

Superior Traction Across All Terrains

ASV tracks deliver exceptional traction, no matter the terrain. Their all-season tread design grips surfaces like mud, gravel, snow, and sand with ease. Operators can confidently navigate steep slopes, uneven ground, or slippery conditions without worrying about losing control.

The adaptable rubber structure plays a key role here. It molds to the terrain, ensuring maximum contact and grip. This feature makes ASV tracks a reliable choice for industries like construction, agriculture, and forestry, where unpredictable ground conditions are common.

Note: Superior traction means fewer delays and more productivity. Operators can keep working even when the weather or terrain gets tough.

Enhanced Stability with Even Weight Distribution

Stability is another standout benefit of ASV tracks. Their Posi-Track system evenly distributes weight across the tracks, reducing pressure on any single point. This design prevents sinking into soft ground and improves flotation, allowing equipment to move smoothly over challenging surfaces.

Operators notice the difference immediately. The machine feels balanced, even when carrying heavy loads or operating on uneven terrain. This stability boosts safety and efficiency, making ASV tracks a preferred choice for tasks that demand precision and reliability.

| Feature | Benefit | Impact |

|---|---|---|

| Even Weight Distribution | Prevents sinking into soft ground | Improved operator confidence |

| Enhanced Flotation | Smooth movement on tough terrain | Reduced downtime |

| Balanced Operation | Safer handling of heavy loads | Increased productivity |

Reduced Environmental Impact withLow Ground Pressure

ASV tracks are designed with the environment in mind. Their low ground pressure minimizes soil disturbance, making them ideal for sensitive areas like wetlands or agricultural fields. Unlike traditional tracks, they leave a lighter footprint, preserving the integrity of the terrain.

This eco-friendly feature doesn’t compromise performance. Operators can complete tasks efficiently while reducing damage to the environment. Industries focused on sustainability, such as landscaping and forestry, benefit greatly from this innovation.

Tip: Choosing ASV tracks means investing in equipment that works hard while protecting the planet.

Real-World Applications of ASV Tracks

Construction and Earthmoving

ASV loader tracks shine in construction and earthmoving projects. Their superior traction allows heavy equipment to navigate muddy or uneven surfaces without slipping. Operators can rely on their stability when carrying heavy loads or working on steep inclines. The even weight distribution prevents machines from sinking into soft ground, which is common on construction sites.

These tracks also reduce wear and tear on equipment. The rubber-on-rubber contact absorbs vibrations, protecting the machine and improving operator comfort. This feature enables longer working hours without fatigue. Whether it’s digging foundations or moving debris, ASV tracks ensure reliable performance in demanding environments.

Agriculture and Forestry

Farmers and foresters benefit greatly from ASV tracks. Their low ground pressure minimizes soil compaction, preserving the health of agricultural fields. This feature is especially useful during planting and harvesting seasons when soil conditions are critical.

In forestry, ASV tracks provide the grip needed to navigate through dense woods and over uneven terrain. Their durability ensures they can handle the rough conditions of logging operations. Operators appreciate the tracks’ ability to maintain traction in wet or snowy conditions, making them a year-round solution for outdoor work.

Landscaping and Snow Removal

ASV tracks excel in landscaping and snow removal tasks. Their specialized tread patterns offer enhanced traction and stability, allowing operators to work efficiently on various surfaces. The wide footprint reduces ground pressure by up to 75%, making them ideal for delicate lawns or gardens.

These tracks also absorb vibrations, providing a smoother ride for operators. This comfort translates to increased productivity during long workdays. Additionally, their extended lifespan offers cost savings over time, making them a smart investment for landscaping and snow removal businesses.

| Benefit | Description |

|---|---|

| Enhanced Traction & Stability | Specialized tread patterns provide exceptional grip on various terrains, improving operational efficiency. |

| Reduced Ground Pressure & Soil Compaction | Wider footprint reduces ground pressure by up to 75%, making them ideal for sensitive surfaces. |

| Vibration Reduction for Operator Comfort | Absorbs machine vibration, leading to a smoother ride and increased operator comfort. |

| Longevity: Cost Savings Over Time | Extended lifespan of tracks offers long-term value despite higher initial investment. |

Maintenance Best Practices for ASV Tracks

Regular Cleaning to Prevent Wear

Keeping ASV tracks clean is one of the easiest ways to extend their lifespan. Dirt, mud, and debris can build up quickly, especially in tough job site conditions. Regular cleaning prevents excessive wear and ensures the tracks perform at their best.

Operators should clean the tracks after each use to avoid debris accumulation. In muddy or abrasive environments, cleaning several times a day is recommended. A pressure washer works well for removing stubborn dirt, while a shovel can help clear the undercarriage.

Tip: Adjust cleaning frequency based on the terrain. Daily cleaning is usually enough, but harsher conditions may require more attention.

Proper Tensioning for Longevity

Track tension plays a big role in maintaining performance. Loose tracks can derail, while overly tight ones may cause unnecessary wear. Operators should check the tension regularly and adjust it as needed.

To find the right tension, consult the equipment manual or follow the manufacturer’s guidelines. A simple test involves lifting the track slightly to check its slack. If it feels too loose or too tight, it’s time for an adjustment.

| Tension Issue | Impact | Solution |

|---|---|---|

| Loose Tracks | Risk of derailment | Tighten to recommended level |

| Overly Tight Tracks | Increased wear and tear | Loosen slightly |

| Properly Tensioned Tracks | Smooth operation and longevity | Regular checks and adjustments |

Inspection and Replacement of Worn Components

Inspecting ASV tracks regularly helps catch issues early. Look for signs of wear, such as cracks, fraying, or missing tread. Pay attention to the undercarriage and rollers, as these areas often experience the most stress.

Replace worn components promptly to avoid further damage. Ignoring small issues can lead to bigger problems, like track derailment or reduced traction. Operators should keep spare parts handy for quick replacements.

Note: A quick inspection before and after each use can save time and money in the long run.

Why Choose ASV Tracks

Unique Features That Set ASV Tracks Apart

ASV rubber tracks stand out due to their innovative design and unmatched performance. Their rubber-on-rubber contact system reduces wear and enhances ride quality. The high-strength polyester wires embedded in the tracks prevent stretching and derailment, ensuring durability. These features make them lighter, rust-free, and more adaptable to various terrains compared to traditional steel tracks.

The Posi-Track system is another game-changer. It evenly distributes weight, reducing ground pressure and improving flotation. This ensures smooth operation on soft or uneven surfaces. Operators benefit from better control, increased safety, and reduced machine stress. These unique features make ASV tracks a reliable choice for demanding tasks across industries.

Long-Term Cost Savings and Efficiency

Investing in ASV tracks pays off in the long run. Operators report significant improvements in maneuverability and traction, which boost productivity. Reduced downtime means fewer interruptions, translating into cost savings.

- Key benefits include:

- Enhanced machine control for better performance.

- Lower maintenance costs due to durable materials.

- Extended track life, reducing replacement frequency.

These advantages make ASV tracks a cost-effective solution for businesses aiming to maximize efficiency while minimizing expenses.

Proven Performance Across Industries

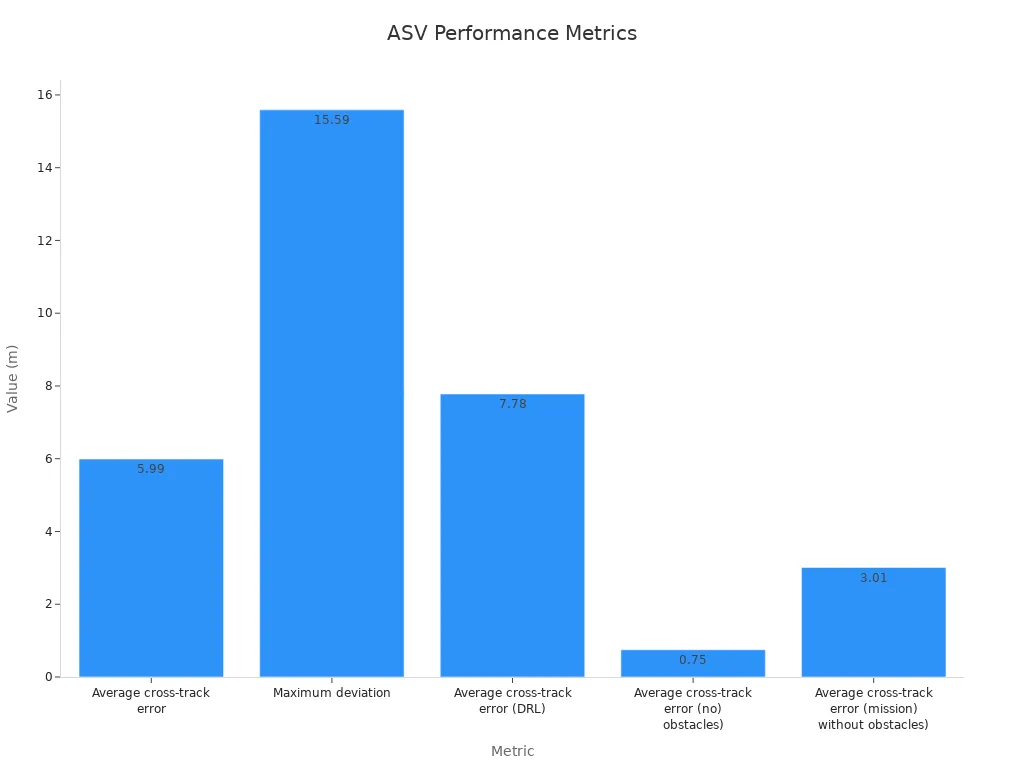

ASV tracks have consistently delivered exceptional results across various applications. Their performance metrics highlight their reliability:

| Metric | Value |

|---|---|

| Average cross-track error | 5.99 m |

| Maximum deviation | 15.59 m |

| Average cross-track error (DRL) | 7.78 m |

| Average cross-track error (no obstacles) | 0.75 m |

The tracks excel in obstacle avoidance and terrain adaptability. They perform exceptionally well in simpler scenarios, with an average cross-track error of just 0.75 m. This level of precision makes them ideal for industries like construction, agriculture, and forestry.

Tip: Businesses looking for reliable, high-performing equipment will find ASV tracks to be a valuable asset.

ASV tracks are transforming ground performance in 2025. Their advanced technology offers unmatched traction, stability, and durability. These features make them a top choice for industries like construction and agriculture. Operators can extend their lifespan by following maintenance tips.

For more details, contact:

- Email: sales@gatortrack.com

- WeChat: 15657852500

- LinkedIn: Changzhou Hutai Rubber Track Co., Ltd.

FAQ

What makes ASV tracks different from traditional tracks?

ASV tracks feature rubber-on-rubber contact, high-strength polyester wires, and the Posi-Track system. These innovations improve durability, traction, and ride quality across all terrains.

Can ASV tracks handle extreme weather conditions?

Yes! Their all-season tread design ensures reliable performance in mud, snow, and rain. Operators can work confidently in any weather without interruptions.

How often should ASV tracks be inspected?

Operators should inspect tracks daily for wear or damage. Regular checks help catch issues early, ensuring optimal performance and extending track lifespan.

Post time: May-09-2025