Excavator rubber track shoes have transformed how you approach excavation tasks. These advanced components, like the HXP500HT Excavator Pads by Gator Track, deliver unmatched efficiency. They improve traction, protect surfaces, and enhance stability during operations. You can rely on them to reduce downtime and boost productivity. Their innovative design ensures smoother performance, even in challenging conditions. Whether you work on sensitive grounds or rugged terrains, these track shoes provide the reliability you need for modern excavation projects.

Key Takeaways

- Excavator rubber track shoes, like the HXP500HT by Gator Track, enhance traction and stability, making excavation tasks more efficient across various terrains.

- These track shoes minimize ground damage, protecting sensitive surfaces such as asphalt and grass, which is crucial for urban and residential projects.

- Rubber track shoes significantly reduce noise and vibrations, creating a quieter work environment, especially important in populated areas.

- Their flexible design allows for better adaptability on uneven or soft surfaces, ensuring consistent performance even in challenging conditions.

- Regular maintenance, including inspections and proper storage, can extend the lifespan of rubber track shoes, maximizing your investment.

- Choosing high-quality options like Gator Track’s HXP500HT pads not only boosts productivity but also reduces operational costs over time.

- Gator Track provides excellent after-sales support, ensuring you have the assistance needed to maintain optimal performance of your excavator rubber track shoes.

Overview of Excavator Rubber Track Shoes

Design and Purpose

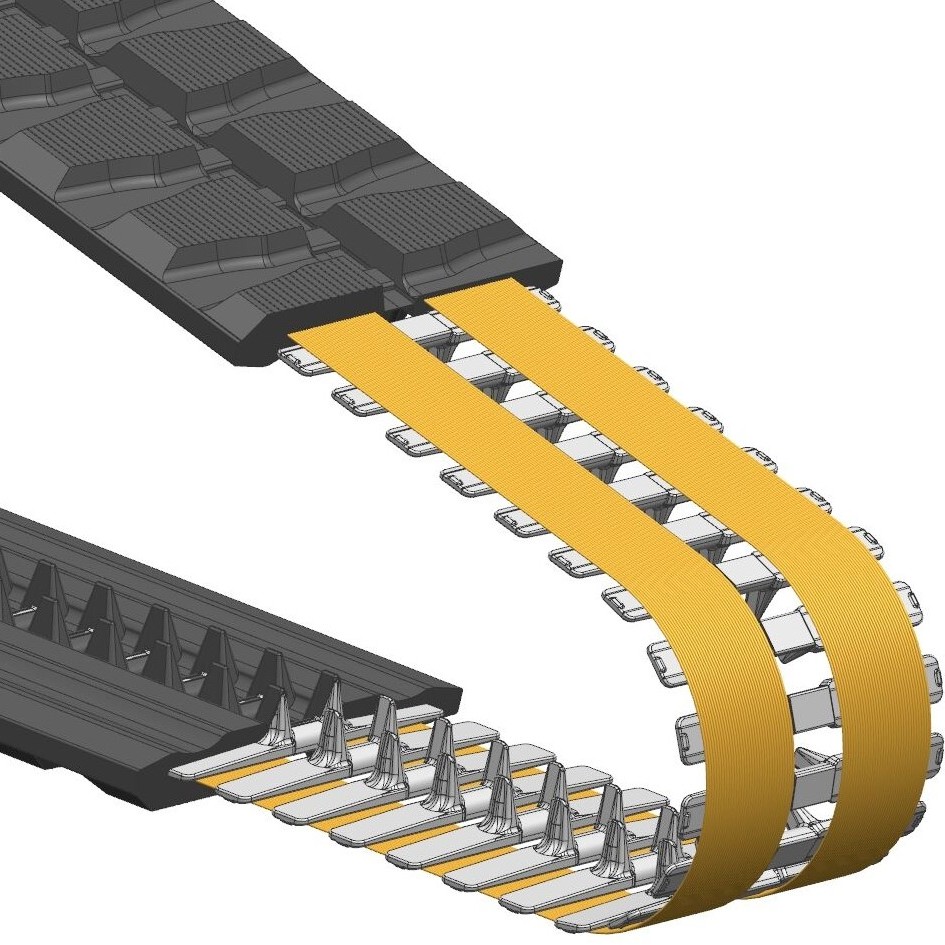

Composition and materials used in rubber track shoes.

Excavator rubber track shoes are crafted using high-quality rubber compounds. These materials combine strength and flexibility, ensuring durability in demanding environments. The rubber is reinforced with steel cores or embedded fibers to enhance structural integrity. This design allows the shoes to withstand heavy loads while maintaining their shape and performance. The unique composition also provides excellent resistance to wear and tear, making them suitable for prolonged use.

How they differ from traditional steel tracks.

Rubber track shoes differ significantly from traditional steel tracks. Steel tracks often cause damage to delicate surfaces like asphalt or grass. In contrast, rubber track shoes minimize ground impact, preserving the integrity of sensitive terrains. Steel tracks generate more noise and vibrations during operation, which can disrupt nearby environments. Rubber track shoes reduce these disturbances, offering a quieter and smoother experience. Additionally, rubber tracks adapt better to uneven surfaces, providing enhanced traction and stability.

Key Features

Flexibility and adaptability to various terrains.

Excavator rubber track shoes excel in versatility. Their flexible design allows them to conform to different terrains, whether you are working on rocky grounds, muddy fields, or paved roads. This adaptability ensures consistent performance across diverse environments. You can rely on them to maintain grip and stability, even on slopes or rugged surfaces. Their ability to handle varying conditions makes them an essential tool for modern excavation tasks.

Noise reduction and vibration dampening.

Rubber track shoes significantly reduce noise levels during operation. The rubber material absorbs sound, creating a quieter work environment. This feature proves invaluable in urban areas or residential projects where noise restrictions apply. Vibration dampening is another key advantage. The rubber absorbs shocks and vibrations, protecting the excavator’s components from excessive wear. This not only extends the machine’s lifespan but also enhances operator comfort by reducing fatigue.

Introduction to Gator Track’s HXP500HT Excavator Pads

High-quality construction and durability.

The HXP500HT Excavator Pads by Gator Track stand out for their exceptional construction. These pads use premium rubber and advanced manufacturing techniques to ensure durability. Their robust design allows them to endure tough working conditions without compromising performance. You can trust these pads to deliver consistent results, even in the most challenging excavation projects.

Designed for a wide range of excavators and tough conditions.

Gator Track’s HXP500HT pads are engineered for versatility. They fit a wide variety of excavators, making them a practical choice for contractors with diverse equipment. Their design ensures reliable performance in harsh environments, including wet, muddy, or rocky terrains. Whether you are working on a construction site or a landscaping project, these pads provide the support and reliability you need to get the job done efficiently.

Key Benefits of Excavator Rubber Track Shoes

Enhanced Traction

Improved grip on slippery or uneven surfaces.

Excavator rubber pads provide superior grip when working on slippery or uneven surfaces. The rubber material molds itself to the ground, creating a stable connection between the excavator and the terrain. This feature ensures that your machine maintains control, even on challenging surfaces like loose gravel or wet rocks. With better traction, you can operate confidently without worrying about slippage or loss of balance.

Better performance in wet or muddy conditions.

Rubber track shoes excel in wet or muddy environments. The flexible design prevents the tracks from sinking too deeply into soft ground, allowing your excavator to move smoothly. The rubber material resists clogging, which helps maintain consistent performance in muddy conditions. This capability ensures that your projects stay on schedule, even when the weather or terrain becomes less than ideal.

Reduced Ground Damage

Minimizing impact on sensitive surfaces like asphalt or grass.

Rubber track shoes protect delicate surfaces during excavation tasks. Unlike steel tracks, which can scratch or dent asphalt, rubber tracks distribute the machine’s weight evenly. This reduces the risk of damage to paved roads or landscaped areas. You can work on sensitive grounds, such as residential lawns or urban streets, without leaving behind unsightly marks or costly repairs.

Preventing deep ruts and soil displacement.

Rubber track shoes prevent deep ruts and excessive soil displacement. The wide surface area spreads the excavator’s weight, reducing pressure on the ground. This feature is especially useful in agricultural or landscaping projects, where preserving the natural state of the soil is crucial. By minimizing ground disturbance, you can maintain the integrity of the worksite while completing your tasks efficiently.

Improved Stability and Durability

Increased balance on uneven terrain.

Rubber track shoes enhance stability on uneven terrain. The flexible rubber conforms to the ground, providing a steady base for your excavator. This increased balance allows you to operate safely on slopes, rocky areas, or other challenging landscapes. With better stability, you can focus on precision and productivity without compromising safety.

Longer lifespan compared to traditional tracks in certain conditions.

Rubber track shoes often last longer than steel tracks in specific conditions. The rubber material resists wear and tear caused by abrasive surfaces, extending the lifespan of the tracks. Additionally, the reduced vibration and noise levels protect the excavator’s components, further enhancing durability. By choosing rubber track shoes, you invest in a solution that delivers long-term value and reliability.

Competitive Advantages of HXP500HT Pads

Superior performance and global customer satisfaction.

The HXP500HT Excavator rubber track Pads deliver unmatched performance in the field. Their robust construction ensures they can handle the most demanding excavation tasks without compromising efficiency. You can rely on these pads to maintain stability and traction, even in challenging conditions like muddy or rocky terrains. This reliability allows you to complete projects faster and with greater precision.

Customers worldwide trust the HXP500HT pads for their exceptional quality. Professionals from industries such as construction, agriculture, and landscaping consistently praise their durability and adaptability. These pads have earned a reputation for meeting the needs of diverse excavation projects, making them a preferred choice for contractors and operators globally. When you choose the HXP500HT pads, you join a community of satisfied users who value performance and dependability.

Competitive pricing and excellent after-sales service.

The HXP500HT pads offer premium quality at a price that fits your budget. Gator Track prioritizes affordability without sacrificing the durability or functionality of its products. This balance ensures you get the best value for your investment. Whether you manage a small operation or a large-scale project, these pads provide cost-effective solutions for your excavation needs.

Gator Track’s commitment to customer satisfaction extends beyond the sale. The company provides responsive after-sales support to address any questions or concerns you may have. Their team ensures you receive timely assistance, helping you maintain the performance of your excavator rubber track shoes. With Gator Track, you gain access to a reliable partner dedicated to your success.

Common Excavation Challenges Solved

Uneven Terrain

How rubber track shoes provide better adaptability.

Rubber track shoes adapt seamlessly to uneven terrain. Their flexible design molds to the contours of the ground, ensuring a stable connection between your excavator and the surface. This adaptability allows you to work efficiently on rocky landscapes, loose gravel, or soft soil. By using rubber track shoes, you can maintain control and precision, even when the terrain presents unexpected challenges.

Maintaining stability on slopes and rugged surfaces.

Operating on slopes or rugged surfaces often feels risky. Rubber track shoes enhance stability by distributing the excavator’s weight evenly. This balance reduces the chances of tipping or sliding, giving you confidence while working on inclines or uneven ground. The improved grip ensures that your machine stays steady, allowing you to focus on completing tasks safely and effectively.

Minimizing Wear and Tear

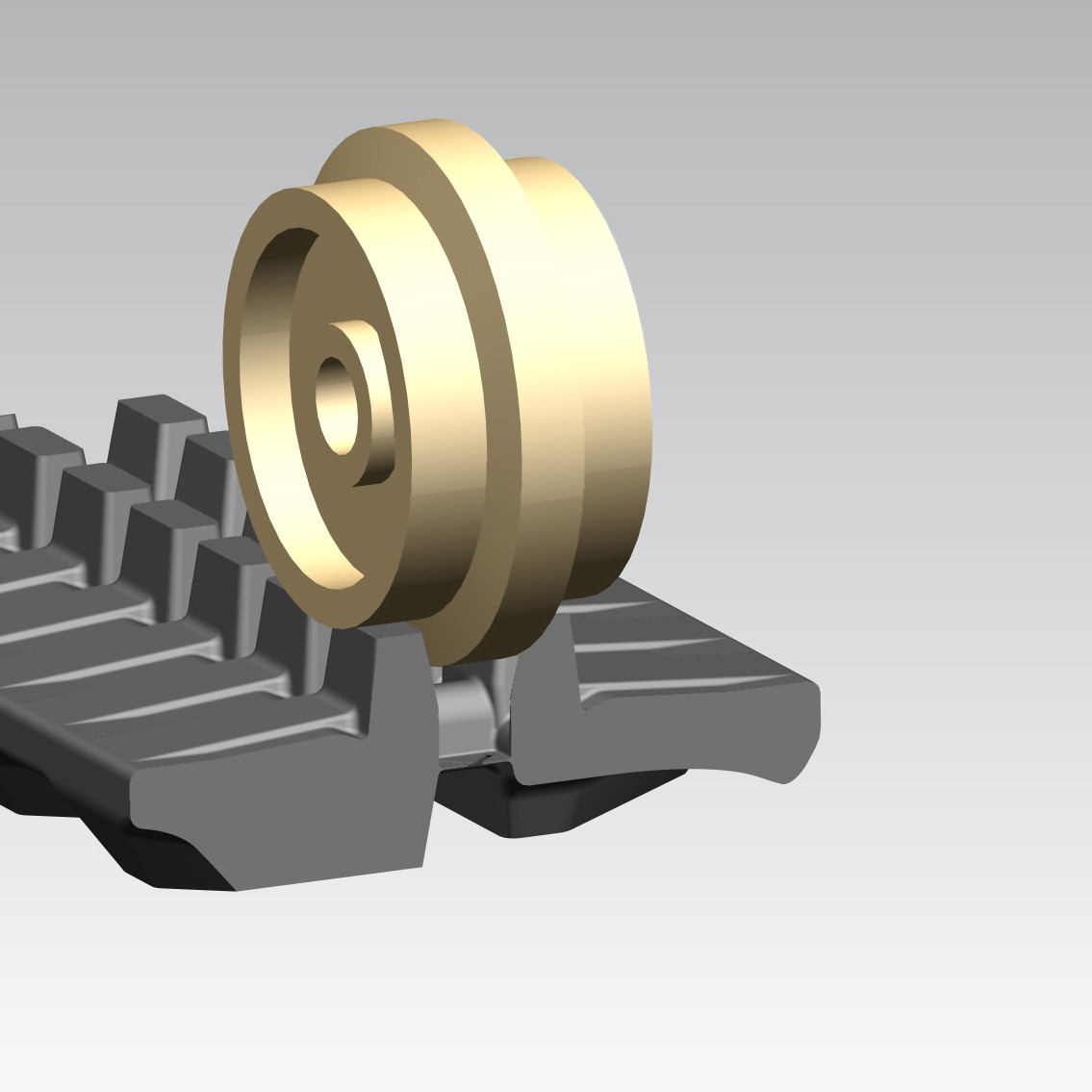

Reducing stress on the excavator’s undercarriage.

Rubber track shoes absorb shocks and vibrations during operation. This feature reduces the strain on your excavator’s undercarriage, protecting critical components from excessive wear. By minimizing stress, you can avoid costly repairs and extend the lifespan of your equipment. Rubber track shoes act as a protective layer, ensuring your machine performs reliably over time.

Extending the life of the machine and its components.

The durability of rubber track shoes contributes to the longevity of your excavator. Their robust construction withstands harsh conditions, preventing damage to essential parts. By reducing friction and impact, these track shoes help preserve the integrity of your machine. Investing in high-quality rubber track shoes ensures that your equipment remains operational for years, saving you money on replacements and repairs.

Reducing Downtime

Faster transitions between different types of terrain.

Rubber track shoes enable quick adjustments when moving between various terrains. Their adaptable design allows you to transition smoothly from hard surfaces to soft ground without losing traction. This efficiency minimizes delays, keeping your projects on schedule. You can rely on rubber track shoes to maintain consistent performance, regardless of the environment.

Lower maintenance requirements compared to steel tracks.

Rubber track shoes require less maintenance than traditional steel tracks. Their material resists wear and tear, reducing the need for frequent inspections or repairs. You spend less time addressing issues and more time focusing on your work. With lower maintenance demands, rubber track shoes help you maximize productivity and reduce operational costs.

How HXP500HT Pads Address These Challenges

Robust construction for tough working conditions.

The HXP500HT Excavator Pads are built to handle the most demanding excavation tasks. Their design incorporates premium rubber and reinforced materials, ensuring they withstand heavy loads and harsh environments. You can rely on these pads to maintain their integrity, even when working on rocky terrains or in extreme weather conditions. The robust construction minimizes wear and tear, allowing you to focus on completing your projects without interruptions.

These pads excel in providing consistent performance across various terrains. Whether you are navigating muddy fields, uneven slopes, or compacted soil, the HXP500HT pads deliver the stability and traction you need. Their durability ensures that they remain effective over time, reducing the need for frequent replacements. By choosing these pads, you invest in a solution that supports your operations in the toughest conditions.

Trusted by professionals worldwide for reliability.

Professionals across industries trust the HXP500HT Excavator Pads for their proven reliability. Contractors, landscapers, and agricultural workers consistently praise these pads for their ability to meet the demands of diverse projects. You can join a global network of satisfied users who depend on these pads to enhance their excavation efficiency.

The HXP500HT pads have earned a reputation for delivering exceptional results. Their adaptability makes them suitable for a wide range of excavators, ensuring compatibility with your equipment. Customers from countries like the United States, Canada, and Australia value their performance and durability. When you use these pads, you gain confidence knowing they are backed by positive feedback from professionals worldwide.

“The HXP500HT pads are a game-changer for excavation tasks. Their quality and reliability make them an essential tool for any project.” – A satisfied customer.

By selecting the HXP500HT Excavator Pads, you align yourself with a product trusted by experts. Their consistent performance and global recognition make them a reliable choice for tackling excavation challenges effectively.

Post time: Mar-17-2025