Rubber tracks revolutionize how your skid loader performs. Products like the Rubber Track T450X100K by Gator Track deliver unmatched traction and stability. These tracks reduce ground damage, making them ideal for sensitive environments. They tackle challenges like wear and tear while adapting to various terrains. This ensures your machine operates efficiently and lasts longer. Choosing high-quality skid loader tracks and maintaining them properly allows you to maximize their benefits and keep your equipment in top condition.

Key Takeaways

- Rubber tracks enhance traction and stability, allowing skid loaders to operate efficiently on challenging surfaces like mud, sand, and gravel.

- These tracks distribute weight evenly, reducing ground pressure and minimizing damage to sensitive environments, making them ideal for landscaping and construction.

- Investing in high-quality rubber tracks, such as the T450X100K, ensures durability and longevity, reducing the need for frequent replacements and saving costs.

- Regular maintenance, including cleaning and inspections, is crucial for extending the lifespan of rubber tracks and ensuring optimal performance.

- Choosing the right tread pattern and track width based on your specific terrain can significantly improve your skid loader’s efficiency and adaptability.

- Proper storage of rubber tracks protects them from environmental damage, ensuring they remain in top condition for future use.

Key Benefits of Rubber Tracks

Enhanced Traction

Rubber tracks provide superior grip on challenging surfaces. When you operate your skid loader on loose terrain like gravel or sand, these tracks ensure better control and stability. They reduce the risk of slipping, even in wet or muddy conditions. This enhanced traction allows you to work efficiently, regardless of the environment. By using high-quality skid loader tracks, you can tackle demanding tasks with confidence.

Increased Stability

Rubber tracks improve the overall stability of your skid loader. They reduce machine vibration, which results in smoother operation and less wear on your equipment. On slopes or uneven ground, these tracks help maintain balance, preventing tipping or instability. This added stability ensures safer and more precise handling, especially in difficult working conditions.

Lower Ground Pressure

Rubber tracks distribute the weight of your skid loader evenly across the ground. This minimizes soil compaction, making them ideal for landscaping projects or other tasks in sensitive environments. The reduced ground pressure also prevents damage to delicate surfaces, such as lawns or paved areas. With skid loader tracks designed for lower ground pressure, you can protect the terrain while maintaining peak performance.

Addressing Common Skid Loader Challenges

Durability and Longevity

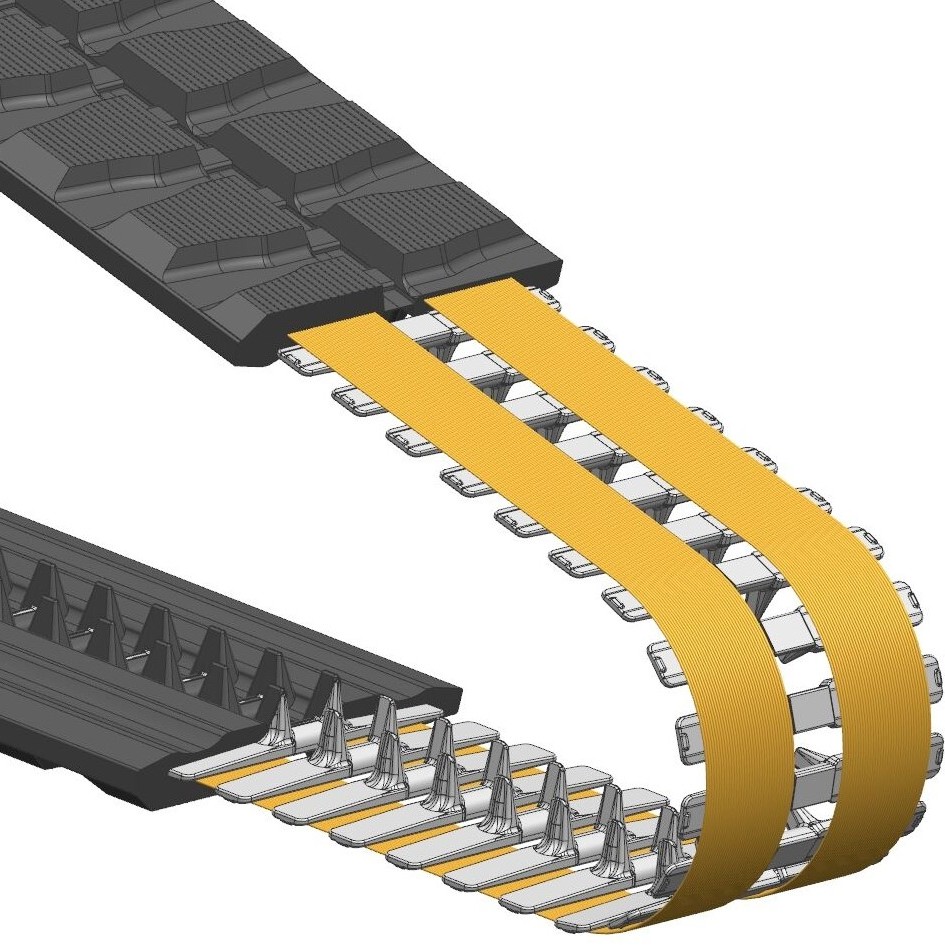

Rubber tracks, like the T450X100K, are built to last. Manufacturers use tear-resistant materials and steel cores to ensure these tracks withstand demanding conditions. This design enhances their lifespan, making them a reliable choice for your skid loader. Unlike pneumatic tires, rubber tracks resist punctures and wear. This durability reduces the need for frequent replacements, saving you time and money. By investing in high-quality skid loader tracks, you ensure your equipment performs efficiently over the long term.

Wear and Tear

Even weight distribution is a key feature of rubber tracks. This design minimizes excessive wear, keeping your skid steer rubber tracks in better condition for longer periods. Regularly inspecting your tracks helps you identify early signs of wear. Look for cracks, cuts, or uneven treads during your routine checks. Addressing these issues promptly prevents further damage and ensures your skid loader operates at its best. Maintaining your tracks properly extends their usability and keeps your machine running smoothly.

Terrain Adaptability

Rubber tracks excel in adapting to various terrains. Whether you work on gravel, sand, mud, or snow, these tracks provide consistent performance. Their versatility allows you to handle different environments without compromising efficiency. On challenging surfaces, rubber tracks reduce slippage, giving you better control over your skid loader. This adaptability makes them an essential component for tackling diverse tasks with confidence and precision.

Maintenance Practices for Optimal Performance

Proper maintenance ensures your skid loader tracks perform efficiently and last longer. By following these practices, you can prevent damage, reduce downtime, and maximize the lifespan of your equipment.

Regular Cleaning

Debris and mud can accumulate on your tracks during operation. This buildup increases wear and reduces performance. You should remove dirt and debris after each use. Use tools like a pressure washer to clean the tracks thoroughly. Focus on areas where mud or stones may get lodged. Keeping your tracks clean prevents unnecessary damage and ensures smooth operation.

Routine Inspection

Frequent inspections help you identify potential issues before they escalate. Check your tracks for cracks, cuts, or uneven wear. Examine the treads to ensure they remain intact and functional. Inspect the undercarriage components, including rollers and sprockets, for alignment and damage. Addressing these problems early keeps your skid loader tracks in optimal condition and avoids costly repairs.

Proper Storage

Storing your tracks correctly protects them from environmental damage. Keep them in a cool, dry place to prevent degradation. Avoid exposing them to direct sunlight or chemicals, as these can weaken the rubber over time. If you store your equipment for extended periods, ensure the tracks are clean and free from debris. Proper storage practices maintain the quality and durability of your tracks.

By implementing these maintenance practices, you can extend the life of your skid loader loader tracks and ensure consistent performance. Regular care not only saves money but also enhances the efficiency of your equipment.

Post time: Apr-01-2025