When it comes to heavy machinery, excavators are among the most versatile and essential tools in the construction, landscaping, and mining industries. However, the performance and safety of these machines can be significantly affected by the components they use. One often-overlooked component is the excavator rubber pads. These pads play a vital role in the machine’s overall functionality, and understanding their importance can improve the performance and lifespan of your equipment.

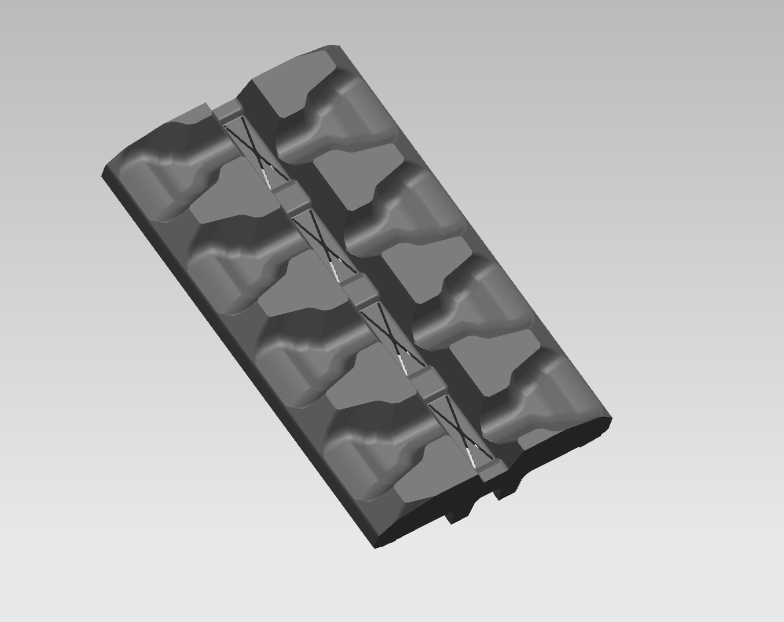

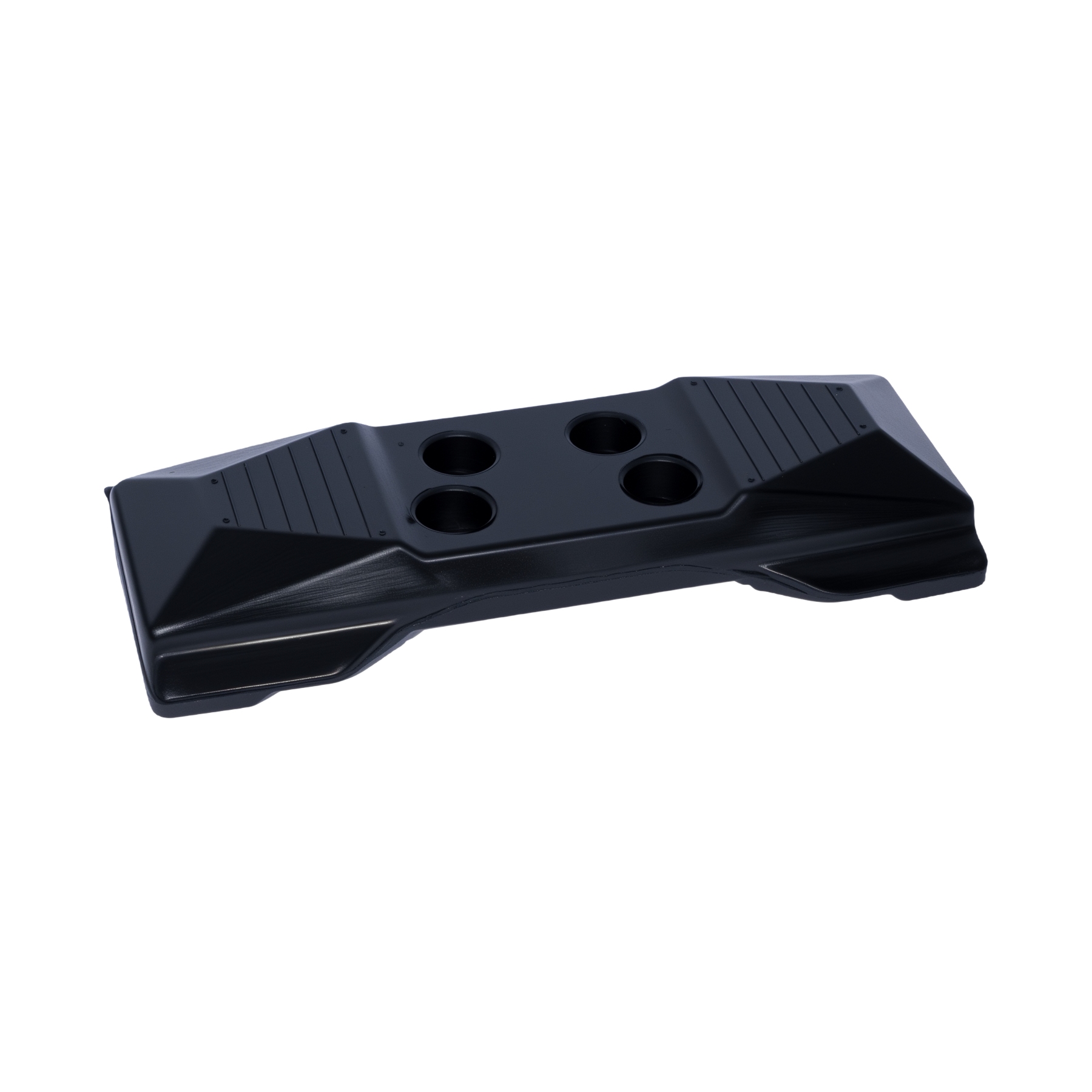

What are excavator rubber pads?

Rubber pads are specially designed attachments that fit onto an excavator’s tracks. Unlike traditional steel tracks, rubber pads have a softer, more flexible surface that adapts to a variety of terrains. They are particularly beneficial for excavators operating in urban environments or on delicate surfaces such as asphalt or concrete, where traditional steel tracks can cause damage.

Benefits of using rubber mats

1. Reduced Ground Damage: One of the main benefits of rubber mats is their ability to minimize ground damage. The softer material distributes the excavator’s weight more evenly, reducing the risk of rutting and other ground damage. This is particularly important in residential areas or construction sites, where ground integrity is paramount.

2. Enhanced Traction: The rubber pads provide excellent traction on a variety of surfaces, including mud, gravel, and sand. This enhanced grip allows the excavator to operate more efficiently, reduces the likelihood of slipping, and improves overall productivity. Operators can work confidently, knowing their machine will remain stable even in challenging conditions.

3. Reduced Noise: Heavy machinery generates noise when in operation, which can be a problem in urban environments or near residential areas. Rubber pads for excavators help reduce noise generated by the tracks, resulting in quieter operation. This not only improves the operator’s working environment but also helps maintain good relations with nearby residents.

4. Versatility: Rubber mats are available in a variety of sizes and designs to suit a wide range of excavator models. Whether you own a small or large excavator, there’s a rubber mat to suit your specific needs. This versatility allows operators to customize their machine for different jobsites and applications.

5. Cost-effectiveness: While the initial investment in rubber tracks may be higher than traditional steel tracks, the long-term benefits often outweigh the cost. By reducing ground damage and wear on the excavator itself, rubber tracks can reduce maintenance costs and extend equipment life. Furthermore, this increased efficiency can shorten project completion times, ultimately saving costs.

Choose the right rubber pad

When choosing rubber mats for excavators, it’s important to consider a variety of factors, such as the type of work you’ll be performing, the terrain you’ll be operating on, and the specific model of excavator. Consulting with an experienced supplier can help you make an informed decision and ensure you select the right rubber mats for your needs.

In summary

Excavator pads are more than just an accessory; they’re key components that enhance machine performance, safety, and efficiency. By choosing high-quality rubber mats, operators can enjoy numerous benefits, such as reduced ground damage, improved traction, lower noise levels, and improved overall cost-efficiency. As the construction and landscaping industries continue to evolve, the importance of such innovations cannot be underestimated. Adopting rubber mats is a step toward more sustainable and efficient on-site operations.

Post time: Oct-13-2025