Key Takeaways

- Skid loader tracks improve grip and balance on slippery or rough ground.

- Strong materials like tough rubber or steel make tracks last longer, cutting repair costs and work delays.

- Tracks spread weight evenly, lowering ground pressure and keeping surfaces safe, perfect for yard work and building jobs.

Key Features of Skid Loader Tracks

Traction and Stability

Skid loader tracks are designed to provide exceptional traction and stability, even in the toughest conditions. Their specialized tread patterns grip slick surfaces like mud or loose gravel with ease. This feature ensures that the machine doesn’t lose its footing, even when the ground is slippery. Additionally, aggressive, self-cleaning treads prevent debris buildup, which helps maintain consistent performance. These tracks also enhance stability on slopes and uneven terrain, reducing the risk of tipping and making operations safer.

By improving traction, skid loader tracks allow the machine to use its engine power more efficiently. This means less energy is wasted on slippage, and more is directed toward getting the job done. Whether you’re working on a construction site or navigating a muddy field, these tracks keep your loader steady and reliable.

Durability and Resilience

Durability is a standout feature of skid loader tracks. They are built to withstand harsh environments and heavy use. High-quality materials, like reinforced rubber or steel, ensure these tracks can handle sharp rocks, rough surfaces, and extreme weather without wearing out quickly. This resilience means fewer replacements and repairs, saving both time and money.

Moreover, skid loader tracks are designed to resist punctures and tears. This makes them ideal for demanding tasks where other equipment might fail. Their long lifespan ensures they remain a cost-effective choice for operators who need reliable performance day after day.

Ground Pressure and Weight Distribution

One of the most impressive features of skid steer rubber tracks is their ability to distribute weight evenly. Unlike wheeled machines, which can create deep ruts in soft ground, these tracks spread the machine’s weight over a larger surface area. This reduces ground pressure by up to 75%, making them perfect for delicate surfaces like lawns or wetlands.

This optimized weight distribution not only protects the ground but also improves the machine’s efficiency. By minimizing sinking and slippage, skid loader tracks allow operators to work faster and more effectively. Whether you’re landscaping or working on a construction site, this feature ensures smooth and steady progress.

Versatility Across Terrains

Skid loader tracks shine when it comes to versatility. They perform exceptionally well on a variety of terrains, from rocky paths to muddy fields. Their superior traction and reduced ground pressure make them suitable for challenging environments where wheeled machines might struggle.

These tracks are also ideal for tight spaces, offering excellent maneuverability. This adaptability makes them a go-to choice for industries like construction, landscaping, and agriculture. No matter the task or terrain, skid loader tracks provide the reliability and performance operators need to get the job done.

Benefits of Skid Loader Tracks

Enhanced Performance in Challenging Conditions

Skid loader tracks excel in tough environments where traditional tires might struggle. Their design allows machines to navigate muddy fields, snowy landscapes, and rocky terrains with ease. The tracks’ superior traction ensures that the loader maintains a firm grip, even on slippery or uneven surfaces. This feature not only boosts performance but also reduces the risk of accidents. Operators can confidently tackle challenging tasks, knowing their equipment is up to the job.

Additionally, the self-cleaning treads on many skid loader tracks prevent debris buildup. This keeps the machine running smoothly, even in messy conditions. Whether it’s a construction site or a farm, these tracks help operators work efficiently and safely.

Reduced Ground Disturbance

One of the standout benefits of skid steer loader tracks is their ability to minimize ground disturbance. Unlike wheeled machines, which can leave deep ruts, tracks distribute the machine’s weight evenly across a larger surface area. This reduces ground pressure significantly, making them ideal for delicate surfaces like lawns or wetlands. Wider tracks, in particular, are highly effective on soft ground, preventing sinking and preserving the terrain.

- High-performance rubber tracks reduce ground disturbance in industries like construction, agriculture, and landscaping.

- Less ground disturbance means fewer repairs to the worksite, saving time and resources.

- Skid trails created by these tracks can even reduce soil erosion compared to undisturbed areas.

By protecting the ground, skid loader tracks not only enhance efficiency but also contribute to environmental preservation.

Cost-Effectiveness and Longevity

Skid loader tracks offer a cost-effective solution for operators looking to maximize their investment. Compared to other tracked construction machinery, skid steers are relatively inexpensive to purchase and maintain. The tracks themselves are designed for durability, with features that extend their lifespan and reduce maintenance costs.

- Internal positive drive systems reduce friction, leading to less wear and longer service intervals.

- Some manufacturers offer warranties of up to two years or 2,000 hours, reflecting confidence in their product’s longevity.

- Open undercarriage designs can extend component life by up to 50%, further lowering maintenance expenses.

These features make skid loader tracks a smart choice for operators who want reliable performance without breaking the bank.

Improved Operator Comfort and Efficiency

Modern skid loader tracks are designed with operator comfort in mind. Their ergonomic features reduce fatigue, allowing operators to work longer without discomfort. Properly placed controls and smoother rides contribute to a more pleasant working experience. Many operators report less back pain and strain, thanks to these thoughtful design improvements.

- Ergonomic designs help reduce operator fatigue, boosting productivity.

- Skid loader tracks provide a smoother ride, even on rough terrain, enhancing comfort.

- The evolution of skid-steer loaders has made them more user-friendly for a wider range of operators.

By prioritizing comfort and efficiency, skid loader tracks ensure that operators can focus on their tasks without unnecessary distractions.

Comparing Types of Skid Loader Tracks

Rubber Tracks: Features and Applications

Rubber tracks are a popular choice for skid loaders due to their versatility and performance on soft or uneven surfaces. They provide excellent traction, making them ideal for tasks like landscaping, farming, and light construction. Their lower ground pressure minimizes damage to delicate surfaces, such as lawns or wetlands, ensuring a smoother operation.

Durability is another key feature of rubber tracks. High-quality options, especially those made from 100% virgin rubber, last longer and resist wear better. Operators also benefit from reduced vibrations, which enhance comfort during long work hours. These tracks are perfect for environments where minimizing ground disturbance is critical.

Steel Tracks: Features and Applications

Steel tracks are built for heavy-duty applications and challenging terrains. They excel in extreme conditions, such as muddy, rocky, or icy surfaces, making them a go-to choice for industries like demolition, forestry, and land clearing. Their exceptional durability ensures they can handle abrasive surfaces without frequent replacements.

Steel tracks also offer increased stability and traction, which are crucial for carrying heavy loads or working on steep slopes. Different types, like steel pad tracks for construction or steel bar tracks for aggressive terrains, cater to specific needs. While they may cause more ground disturbance, their longevity and performance make them a reliable option for demanding tasks.

| Feature | Description |

|---|---|

| Increased Stability | Steel tracks enhance stability and traction, crucial for control during challenging tasks. |

| Performance in Extreme Conditions | Steel tracks improve performance on muddy, rocky, and icy surfaces, suitable for various industries. |

| Exceptional Durability | Known for wear resistance, ideal for heavy-duty applications on abrasive surfaces. |

| Longevity | Longer lifespan than rubber tracks, reducing replacement frequency and maintenance costs. |

Choosing the Right Tracks for Your Needs

Selecting the right tracks depends on your operational requirements. Rubber tracks are ideal for soft terrains and projects requiring minimal ground disturbance. They also reduce vibrations, improving operator comfort. On the other hand, steel tracks are better suited for heavy-duty tasks and extreme conditions.

Consider the pros and cons of each type. Rubber tracks offer lower ground pressure and smoother rides but may wear faster on abrasive surfaces. Steel tracks provide unmatched durability and stability but can damage delicate grounds. By evaluating your specific needs, you can choose the best tracks to maximize efficiency and performance.

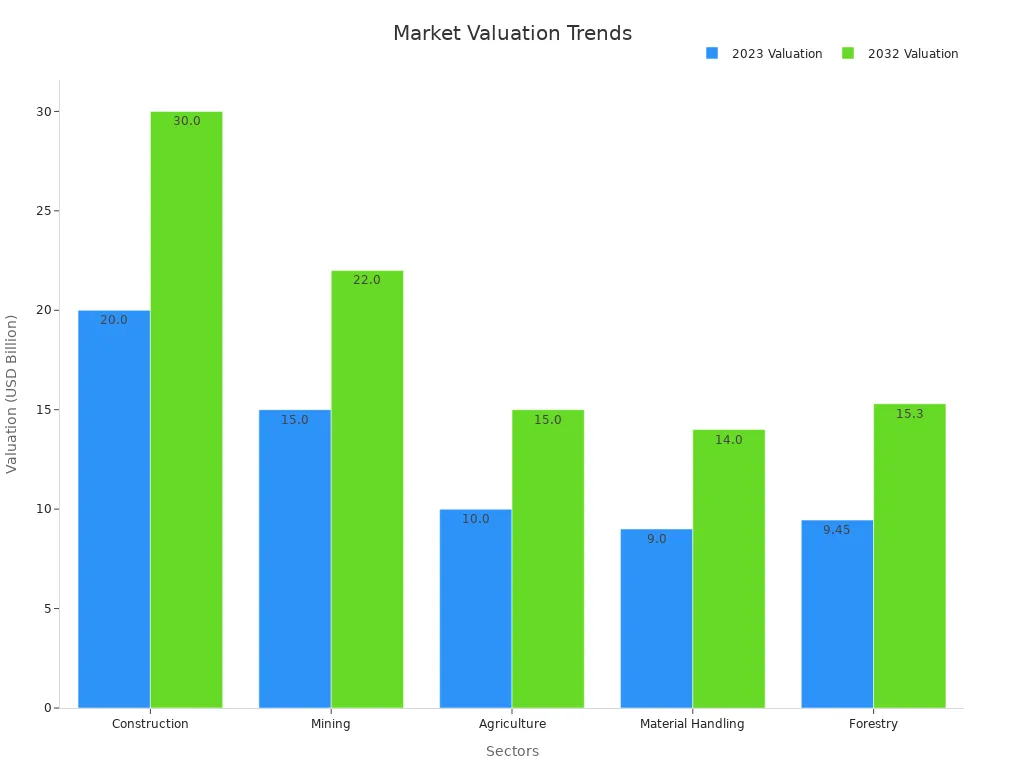

Tracks for skid loader offer unmatched traction, durability, and versatility, making them essential for various industries. Choosing the right tracks ensures optimal performance and cost-efficiency. For instance, market data highlights the growing demand across sectors:

| Sector | 2023 Valuation (USD Billion) | Projected 2032 Valuation (USD Billion) |

|---|---|---|

| Construction | 20.0 | 30.0 |

| Mining | 15.0 | 22.0 |

| Agriculture | 10.0 | 15.0 |

| Material Handling | 9.0 | 14.0 |

| Forestry | 9.45 | 15.3 |

Gator Track stands out as a trusted provider, serving markets in the U.S., Canada, Europe, and beyond. Their strong partnerships and same-day after-sales support ensure customer satisfaction. Explore Gator Track’s offerings to find the perfect tracks for your needs.

Contact Us:

- Email: sales@gatortrack.com

- WeChat: 15657852500

- LinkedIn: Gator Track LinkedIn

FAQ

What are skid loader tracks made of?

Skid loader tracks are typically made from durable materials like reinforced rubber or steel. These materials ensure long-lasting performance and resistance to wear and tear.

How do skid loader tracks improve performance?

Tracks enhance traction, reduce ground pressure, and provide stability. This allows skid loaders to operate efficiently on challenging terrains like mud, snow, or rocky surfaces.

Post time: May-06-2025