I see agricultural tracks as the strategic choice for modern farms in 2025. These systems offer unparalleled advantages over traditional tires. They excel in traction, soil health, efficiency, and operator comfort. I find agricultural rubber tracks, in particular, lead the way for superior performance and sustainability.

Key Takeaways

- Agricultural tracks give farm machines better grip. This means less fuel use and faster work.

- Tracks help keep farm soil healthy. They spread the machine’s weight. This helps crops grow better.

- Tracks last a long time. They save money on repairs. They make farming more efficient.

Enhanced Traction and Versatility with Agricultural Tracks

Superior Grip and Reduced Slippage

I find that agricultural tracks give machines a much better grip on the ground. This superior grip means less slippage. When a machine slips less, it uses its power more effectively. This directly translates to several important benefits for my farm.

- Reduced Fuel Consumption: Machines with less slippage need fewer working hours to cover the same area. This means I use less fuel.

- Decreased Operational Time: My equipment can cover more ground in the same amount of time. This reduces overall operational hours.

- Reduced Hourly Operating Costs: Lower fuel use and less time working mean lower costs per hour.

- Increased Yield: Independent tests show a measurable yield increase of approximately €30 per hectare. This is a significant gain.

Adaptability to Diverse Field Conditions

I see agricultural tracks as incredibly versatile. They spread the machine’s weight over a larger area. This means my equipment can work effectively in many different soil types. I can move from soft, sandy fields to firmer, clay-rich ground without issues. Tracks also handle uneven terrain very well. They conform to the ground’s contours. This gives my machines stability and consistent performance. I can work confidently across my entire farm, no matter the field’s condition.

Maintaining Performance in Challenging Weather

I know that challenging weather can stop farm work. However, agricultural tracks help me keep going. They perform very well in wet or muddy fields. I have seen how certain track surfaces improve year-round usability.

- Tar and chip surfaces improve year-round usability in rural environments. These areas often have significant rain and runoff.

- They help with water runoff because they have a naturally porous surface.

- They prevent standing water and mud patches.

- They provide safer and cleaner access in wet weather.

Tarmac agricultural tracks show strong performance in challenging wet conditions. This is because they are impermeable. This feature prevents rutting caused by rain or standing water. It ensures the surface stays usable all year, even during very wet winters. I can rely on my equipment to perform, even when the weather turns bad.

Agricultural Tracks for Reduced Soil Compaction and Healthier Farms

Preserving Soil Structure and Fertility

I know how important healthy soil is for my farm. Track systems help me keep my soil healthy. They reduce soil compaction. Their larger surface area spreads the tractor’s weight evenly. This minimizes the pressure on the soil. This is very important for keeping the soil structure and health good. Healthy soil directly helps my crops grow better.

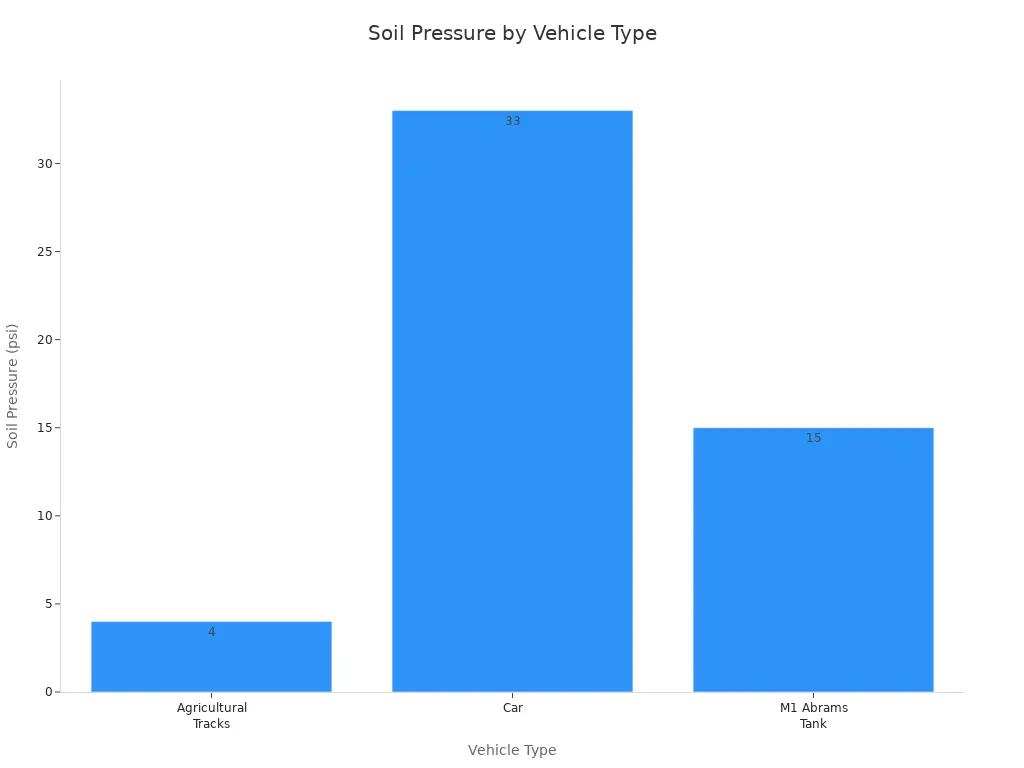

Agricultural tracks distribute weight evenly. They can reduce soil pressure to as low as 4 psi. I find this amazing. Think about it: a car puts up to 33 psi on the ground. Even an M1 Abrams tank puts over 15 psi. My tracks are much gentler.

| Vehicle Type | Soil Pressure (psi) |

|---|---|

| Agricultural Tracks | 4 |

| Car | 33 |

| M1 Abrams Tank | 15 |

Tracked tractors also affect soil moisture less. Wheeled tractors on wet soil can really change soil bulk density and porosity. My tracks help avoid these problems. Rubber tracks reduce soil compaction compared to tires. They help keep the soil structure good during harvest. This helps my soil stay healthy and productive for a long time.

Improving Water Infiltration and Aeration

When I reduce soil compaction, I also help water and air move better through the soil. Healthy soil needs good water infiltration. It also needs good aeration. This means water can soak into the ground easily. Air can also reach the plant roots. This creates a better environment for roots to grow.

Farmers who switch to tracks often see clear improvements in their crops. I notice taller plants and wider root spread. My yields also increase. This shows me that tracks make the soil healthier. Roots can grow freely. Water can go deep into the soil. The soil stays loose and has plenty of air.

Boosting Crop Yields and Long-Term Productivity

Healthy soil directly leads to better crop yields. It also helps my farm stay productive for many years. Avoiding vehicle compaction always gives me positive crop yield responses. These can range from 82% to 190% compared to old traffic systems. This is a huge difference.

Heavy wheel loads, over 5 Mg, can cause lasting damage to the subsoil. This can reduce my yield by 2.5%. I want to avoid this. Avoiding compaction can also increase how well my plants use nutrients by up to 20%. Compaction deep in the soil can last a long time. In sandy soils, it can even last forever.

I see the impact of heavy machinery in just one season:

| Impact of Trafficking in One Season | Value |

|---|---|

| Increase in soil penetration resistance | 47% |

| Increase in bulk density | 15% |

| Reduction in soil porosity | 10% |

| Reduction in infiltration | Factor of four |

| Reduction in wheat yield | Up to 16% |

These numbers show me why tracks are so important. They protect my soil. They help me get better harvests. They ensure my farm stays productive for the future.

Durability, Efficiency, and Cost-Effectiveness of Agricultural Rubber Tracks

Extended Lifespan and Reduced Downtime

I always look for ways to make my farm equipment last longer. Agricultural tracks offer a clear advantage here. They are built tough. This means they can handle the hard work of farming day after day. I find that tracks often outlast traditional tires. This durability means I do not have to replace them as often. When my equipment is working, it is making money. When it is in the shop for repairs or replacements, it costs me money. Tracks help me keep my machines in the field and working. This reduces downtime significantly. I can rely on my tracked equipment to perform when I need it most.

Fuel Savings and Operational Efficiency

I constantly look for ways to make my farm run more efficiently. Agricultural tracks play a big role in this. They help me save fuel and get more work done. I notice that my operators can drive faster with tracks. They also have better control over the machinery. This means tasks get done quicker and more accurately. This is especially true for jobs that need multiple passes.

Tracks keep more of their surface on the ground. This continuous contact helps with planting accuracy. It gives my high-tech farming tools the stability they need. They work seamlessly with my digital farming systems. I also see better power transfer to the ground. This is because tracks have a larger contact area. This design reduces slip. It also prevents soil smearing, especially when I turn. My machines can handle more power without issues, which also helps the tracks last longer. I can pull wider implements with tracks. This means I cover more ground in fewer passes. This is very important when I have a small window of time to work. The ride is also smoother with tracks. This makes my operators more comfortable. They can work longer and stay focused. This leads to faster and more precise work.

Lower Maintenance and Long-Term Value

When I invest in new equipment, I always think about the long-term costs. Tracks might seem like a bigger upfront cost. However, I find they save me money over time.

Let’s look at the numbers for track replacement:

| Track Type | Replacement Interval (Hours) | Maintenance/Repair Savings (5-year period) |

|---|---|---|

| Rubber Tracks | 3,000 to 4,000 | Up to $15,000 (compared to steel tracks) |

| Steel Tracks | 1,000 to 2,000 | N/A |

I see that rubber tracks last much longer than steel tracks. This means I replace them less often. This saves me money on parts and labor. Rubber tracks generally have lower operating costs. They need less frequent maintenance. This makes them more economical over their lifespan. I have noticed fewer repairs and replacements since switching to tracks. This directly lowers my maintenance spending. The increased efficiency and productivity also lead to better crop yields. This makes tracks a smart financial choice for my farm.

I also consider the overall value.

- Tracks offer great grip on various terrains. This includes mud, sand, and hills. They have deep treads and special rubber.

- They are built with strong rubber and sturdy parts. This makes them robust. It gives them a long life and keeps maintenance costs down.

- Tracks handle heavy loads well. They give reliable performance all season.

- They provide maximum stability for my tractors. This makes tasks like plowing, planting, and harvesting safer and more efficient.

I see tracks as a smart long-term investment. They balance quality with budget-friendliness.

I believe agricultural machine rubber tracks are a strategic investment for modern farming. They deliver superior performance, sustainability, and economic benefits. This shift to agricultural tracks is essential for future-proofing my farm operations. I know they will help me succeed.

FAQ

Do agricultural tracks cost more than tires initially?

I find tracks often have a higher upfront cost. However, they offer significant long-term savings. These savings come from better fuel efficiency, less soil damage, and increased productivity.

Can I use tracks on all types of farm equipment?

I see tracks on many machines. You can use them on tractors, combines, and other heavy farm equipment. They adapt well to various models and brands.

How often do I need to replace agricultural tracks?

I have found rubber tracks last 3,000 to 4,000 hours. This is much longer than steel tracks. Their durability means less frequent replacement and lower maintenance costs for me.

Post time: Nov-20-2025