Selecting the right dumper rubber track transforms fleet performance. Operators notice smoother rides and fewer repairs. High-quality tracks, tested from -25°C to 80°C, last up to 5,000 km and save hundreds of maintenance hours. Teams gain confidence, knowing their equipment runs reliably on any terrain.

Key Takeaways

- Choosing high-quality dumper rubber tracks improves fleet performance by providing better grip, longer lifespan, and smoother rides on all terrains.

- Proper maintenance and selecting the right tread design help reduce downtime, lower fuel costs, and extend track life, saving money over time.

- Easy installation and versatile track sizes ensure compatibility with many dumper models, making it simple to keep your fleet running efficiently and safely.

The Role of Dumper Rubber Track in Machinery Performance

Traction, Stability, and Ground Protection

A fleet equipped with the right dumper rubber track can conquer any terrain. Operators see the difference on muddy, rocky, or uneven ground. The unique rubber compound in our tracks delivers maximum grip and smooth maneuverability. This means machines move confidently, even when the ground gets tough.

Advanced tread patterns and sturdy construction help distribute weight evenly. This reduces ground pressure and protects sensitive surfaces from damage. Operators notice less soil compaction and fewer ruts, which keeps job sites cleaner and safer.

Studies show that advanced dumper rubber tracks nearly double operational lifespan compared to standard tracks. They also provide up to 60% more grip, thanks to specialized tread designs. The table below highlights these improvements:

| Feature | Standard Tracks | Advanced/Premium Tracks |

|---|---|---|

| Lifespan (hours) | 500-800 | 1,000-1,500+ |

| Grip Improvement | Baseline | Up to 60% more grip |

Japanese construction firms report a 22% efficiency improvement in earthmoving tasks using automated rubber tracked dumpers. These machines also reduce ground pressure by up to 60%, making them ideal for construction, mining, and landscaping projects.

Enhancing Operator Comfort and Safety

A smooth ride matters. Dumper rubber track systems absorb shocks and vibrations, creating a more comfortable experience for operators. Fully suspended frames and rubber-on-rubber contact reduce fatigue and help operators stay focused throughout long shifts.

Operators feel less tired and more in control, even on rough terrain. This leads to fewer mistakes and safer job sites.

Safety records confirm that improved track designs extend track life by up to 140% and lower maintenance costs. Enhanced traction and stability mean machines grip better on mud, snow, and gravel. Fuel consumption drops by 8% due to efficient weight distribution. Operators also gain more workable days each season, boosting productivity.

Versatility Across Different Applications

Dumper rubber track systems adapt to many tasks. Construction, agriculture, mining, and landscaping all benefit from their versatility. Our tracks fit a wide range of dump trucks, with sizes and configurations to match different models. The most popular size—750 mm wide, 150 mm pitch, and 66 links—ensures seamless integration and easy installation.

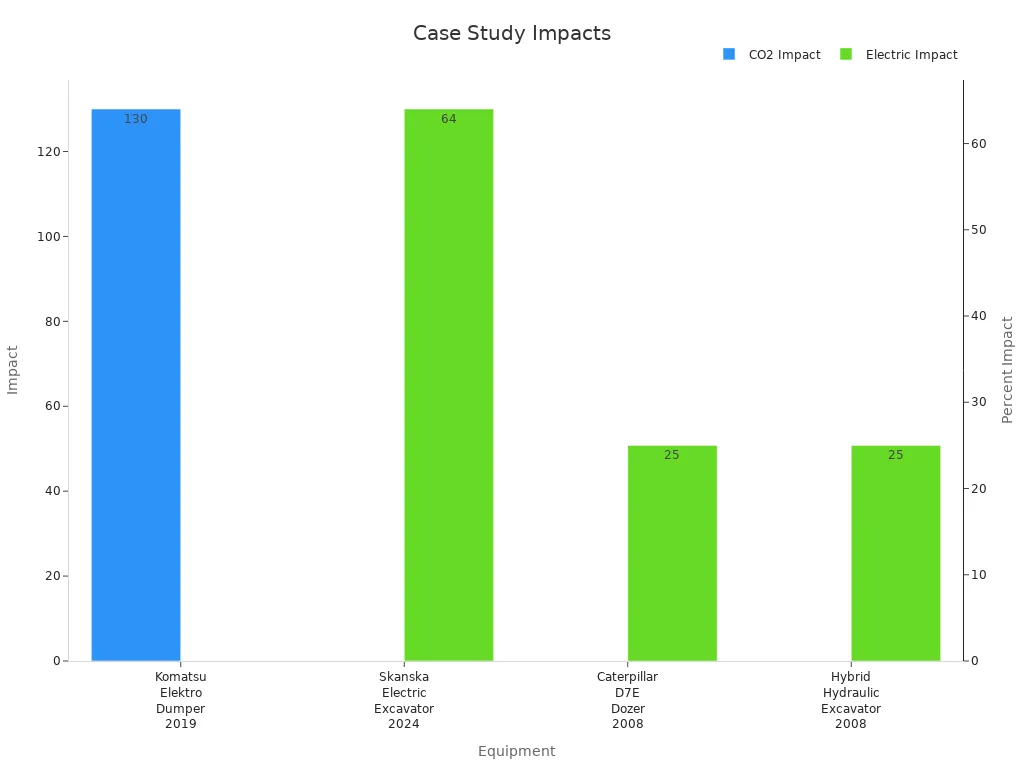

Case studies from leading equipment brands show how versatile dumper rubber tracks support electric, hybrid, and traditional machines. These tracks help reduce emissions, save fuel, and protect the environment. The chart below shows the impact of versatile track systems across various applications:

Adjustable features like track tension and grip customization let operators optimize performance for every job. Durable materials and innovative designs mean less downtime and more time getting work done.

Dumper rubber track technology continues to evolve, meeting the demands of modern fleets. Operators and fleet managers see real results—better efficiency, safer operation, and reliable performance on every site.

Selecting the Best Dumper Rubber Track for Your Fleet

Quality, Material, and Durability

Fleet managers know that quality matters most when choosing tracks. High-quality dumper rubber tracks start with the best raw materials. Manufacturers use advanced rubber compounds, often reinforced with additives like carbon black, to boost strength and resist wear. Every step of production follows strict quality assurance systems, including ISO9001:2015 standards. This means each track meets international benchmarks for durability and safety.

Companies test their tracks with abrasion resistance, tensile strength, and heat tolerance assessments. These tests show how well the tracks handle heavy loads, rough terrain, and extreme temperatures. Independent labs review test reports and certifications, such as CE markings and ASTM standards, to confirm product reliability.

A strong warranty often backs up these claims. It shows confidence in the product’s long life and performance. When a fleet uses tracks built with these standards, downtime drops and productivity rises.

Tread Design and Efficiency

Tread design shapes how a dumper rubber track performs on the job. The right pattern gives machines better grip, smoother rides, and longer life. Engineers use advanced tools like finite element modeling and 3D groove-pattern technology to create treads that boost traction and reduce rolling resistance. These designs help machines move easily over mud, snow, or gravel.

| Performance Metric | Description | Relation to Fuel/Efficiency Benefits |

|---|---|---|

| Traction Rating | Measures stopping ability on wet surfaces | Influences tread design and safety |

| Treadwear Rating | Predicts tire longevity | Longer-lasting tracks keep efficiency high |

| Temperature Rating | Shows heat resistance | Better heat dissipation means less wear and more durability |

| Rolling Resistance | Energy lost when rolling | Lower resistance saves fuel and boosts efficiency |

| Load Index & Speed Rating | Maximum load and speed | Ensures safe, efficient operation |

| Wet Grip Performance | Traction and braking on wet surfaces | Affects safety and rolling resistance |

Designers also study how groove angles, tread depth, and block shapes affect grip and stiffness. For example, a biomimetic tread inspired by goat hooves can increase maximum adhesion by over 14%. These innovations mean operators get more control, less slippage, and better fuel economy. The right tread design turns every job into a success story.

Compatibility, Sizing, and Easy Installation

No two fleets are the same. That’s why dumper rubber tracks come in many sizes and configurations. Manufacturers test their tracks on different dumper models to ensure a perfect fit. Specialized rubber formulas, treated metal cores, and precise vulcanizing processes guarantee that tracks adapt to various machines and terrains.

- Tracks are available in multiple sizes and shapes for different dumpers.

- The most popular size—750 mm wide, 150 mm pitch, and 66 links—fits many models and installs quickly.

- Custom tracks can match unique machines, like the Hitachi CG 45.

- Easy installation means less downtime and more time working.

- Regular checks for tension and alignment keep tracks running smoothly.

Operators appreciate how simple it is to install and maintain these tracks. Quick sizing and compatibility checks prevent mistakes and keep machines safe. Regular cleaning and inspections help spot wear early, so fleets stay productive.

Choosing the right dumper rubber track means every machine in the fleet works at its best. With the right size, design, and quality, teams can tackle any challenge with confidence.

Cost-Effectiveness and Maintenance of Dumper Rubber Track

Long-Term Savings and Reduced Downtime

Fleet owners see real savings when they invest in high-quality dumper rubber tracks. Premium tracks last longer and help machines work better. Operators notice fewer breakdowns and less time spent on repairs. Studies show that these tracks increase durability by about 25%. They also lower fuel use because the tracks roll smoothly and weigh less. Maintenance costs drop since the tracks protect the undercarriage and do not rust. Teams spend less time adjusting or greasing rubber tracks compared to steel ones. Regular care, like cleaning and checking tension, can even double the track’s lifespan. These benefits add up to big savings over the life of the machine.

- Premium rubber tracks extend machine life.

- Fuel costs go down with lighter, smoother tracks.

- Less maintenance means more time working.

- Fewer replacements save money year after year.

High-quality tracks use advanced rubber and steel cords. These features make them tough against wear and heat. Smart Track Technology lets teams monitor track health in real time, stopping problems before they start. Quick support and strong warranties keep machines running and reduce downtime.

Maintenance Tips for Maximum Longevity

Operators who follow expert tips get the most from their dumper rubber tracks. Simple habits make a big difference.

- Stick to weight limits and spread loads evenly.

- Inspect tracks often for cracks or misalignment.

- Clean off mud and debris after every use.

- Keep track tension just right.

- Drive carefully and avoid sharp turns.

- Store tracks in cool, dry places away from sunlight.

- Fix problems early and keep good records.

Regular care helps tracks last longer and keeps machines safe on every job.

Practical Advice for Track Selection

Choosing the right track means matching tread and width to the job. The table below shows which tread patterns work best for different terrains and tasks:

| Tread Pattern | Best For | Key Benefits |

|---|---|---|

| Block Tread | Gravel, lawns, sand, mud | Versatile, works in many conditions |

| Straight Bar | Muddy or wet surfaces | Great traction, protects turf |

| Multi-Bar | Wet, dirt, general construction | All-season, long-lasting |

| Premium C-Pattern | Rocky, demolition, mud | Top traction, extra durability |

| Zig-Zag | Snow, clay, slippery slopes | Prevents sliding, easy to clean |

Wide tracks work well on soft ground and protect surfaces. Narrow tracks help in tight spaces. Tracks with tough rubber and strong steel belts last longer and handle rough jobs. Operators should always check that the track fits their dumper model for easy installation and best results.

Fleet managers see real results when they choose the right tracks. Premium options last longer and reduce downtime. The table below shows how premium tracks double lifespan and cut replacement needs. Regular benchmarking helps teams track progress and unlock new levels of safety, savings, and performance.

| Track Type | Lifespan (Hours) | Replacement Frequency (for 1,000 hours/year) |

|---|---|---|

| Standard Tracks | 500-800 | Every 6-9 months |

| Premium Tracks | 1,000-1,500+ | Every 12-18 months or longer |

FAQ

How do dumper rubber tracks improve job site safety?

Dumper rubber tracks give machines better grip and stability. Operators feel more secure. Teams work with confidence, knowing equipment stays steady on any surface.

Are these tracks easy to install on different dumpers?

Yes! Most tracks fit many dumper models. Operators follow simple steps. Quick installation means less downtime and more time working.

What makes your dumper rubber tracks last longer?

Our tracks use a unique rubber compound. This material resists wear and tear. Operators see fewer replacements and enjoy longer service life.

Post time: Jul-04-2025