I observe 700mm Excavator Rubber Pads are essential. They protect surfaces, reduce noise, and enhance traction for excavators. Both 700mm Rubber Pads and 800mm Rubber Pads offer versatile solutions for various construction and landscaping tasks. The market for these pads shows consistent growth.

Key Takeaways

- Excavator rubber pads protect surfaces, reduce noise, and improve traction. They are good for urban construction and landscaping.

- Buying rubber pads directly from the manufacturer saves money. It also ensures high quality and offers custom options.

- Future rubber pads will use better materials and smart technology. They will also be more sustainable and customizable.

Why Choose 700mm & 800mm Excavator Rubber Pads?

Surface Protection Benefits of Excavator Rubber Pads

I consistently recommend these pads for their excellent surface protection. My experience shows that 700mm and 800mm rubber pads are crucial for preventing damage. They safeguard delicate surfaces like finished concrete, asphalt, and even manicured lawns. This capability avoids expensive site repairs and helps maintain a professional appearance on every job.

Enhanced Traction Advantages of Excavator Rubber Pads

I also observe significant improvements in traction. These specialized pads provide superior grip across diverse terrains. They perform exceptionally well on slippery, wet, or uneven ground conditions. This enhanced traction directly translates to improved operational safety and greater efficiency for my equipment and crew.

Noise Reduction Capabilities of Excavator Rubber Pads

Noise reduction is another compelling reason I choose these pads. The inherent properties of rubber effectively absorb sound. This significantly lowers the overall operational noise levels of excavators. It makes working in noise-sensitive environments, such as urban areas or residential zones, much more considerate and compliant.

Vibration Dampening Effects of Excavator Rubber Pads

I find the vibration dampening effects particularly beneficial. These rubber pads can reduce vibration levels by up to 75%. This impressive reduction often comes from specialized designs, such as those featuring “Diamond Shaped” technology, which ensures a smooth and continuous roller runningway. This not only enhances operator comfort during long shifts but also contributes to extending the lifespan of the machinery itself.

Versatility in Applications for Excavator Pads

Finally, I value the remarkable versatility these pads offer. They adapt seamlessly to a wide array of applications. From demanding urban construction sites to meticulous landscaping projects and golf course maintenance, they provide a flexible and effective solution. This adaptability makes them an indispensable component for various tasks I undertake.

Key Applications for 700mm & 800mm Excavator Rubber Pads in 2026

Urban Construction Projects with Excavator Rubber Pads

I find these pads indispensable for urban construction. They protect surfaces like roads, pavements, and landscaped areas from damage. This is crucial for city infrastructure. I have seen how they reduce machine noise, important in residential areas. They also enhance traction, improving control and stability. My experience shows these pads lead to fewer repairs and faster project completion. I have observed a 20-30% reduction in surface repair costs. For heavy-duty excavation, these pads enhance machine stability and reduce ground vibrations, improving safety.

Landscaping and Golf Course Maintenance with Excavator Rubber Pads

For landscaping and golf course maintenance, I rely on these pads to protect delicate grounds. Traditional surfaces like pea shingle, gravel, or tarmac often cause problems. Rubber solutions address these issues. They provide a smooth, seamless, and durable surface. This surface withstands heavy footfall and harsh weather. It also offers significant safety benefits. I appreciate their durability and weather resistance; they withstand extreme temperatures. They also offer low maintenance and good drainage. The open-hole grid design allows grass to grow through, maintaining a natural look and permitting free water drainage.

Indoor Demolition Work with Excavator Rubber Pads

When I undertake indoor demolition, these pads are essential. They prevent damage to interior flooring and sensitive structures. The reduced vibration and noise are critical in enclosed spaces. This allows for safer, more controlled operations. I find they help maintain a cleaner work environment.

Utility Infrastructure Projects with Excavator Rubber Pads

I consider Excavator Rubber Pads crucial for utility infrastructure projects. They protect valuable urban infrastructure during excavation. This includes vital components like gas lines, water pipes, electrical cables, and telecommunications lines. I ensure my teams use them to prevent costly damage.

Rental Fleet Versatility with Excavator Rubber Pads

For my rental fleet, the versatility of these pads is a major advantage. They allow excavators to be used across a wider range of jobs. This increases their appeal to diverse clients. I find they reduce potential damage claims, a significant benefit for my business.

Selecting the Right 700mm or 800mm Excavator Rubber Pad: What to Look For

I understand choosing the correct 700mm or 800mm excavator rubber pad is a critical decision. This choice directly impacts operational efficiency, safety, and cost-effectiveness. I always consider several key factors before making a purchase.

Material Quality and Durability of Excavator Rubber Pads

I prioritize material quality and durability above all else. High-quality pads offer superior performance and a longer lifespan. I look for specific material properties. These include excellent heat resistance. This is crucial because high temperatures can cause degradation, chain cracking, and changes in material hardness and strength. I also examine the material composition, including additives, curing agents like sulfur, peroxides, metal oxides, antioxidants, and accelerators. The vulcanizing system also matters.

Abrasion resistance is another key factor I consider. Constant friction from materials like rocks and concrete significantly reduces pad lifespan. Reinforcement technologies, such as steel cords, polyester canvas interlayers, wear-resistant covers, and specialized core rubber, enhance this property. Material hardness, measured by durometer readings, indicates resistance to indentation. Higher durometer materials offer superior resistance to abrasion, deformation, and impact. This contributes to extended wear life.

Adhesion strength is vital for pad durability. I ensure strong rubber-to-metal bonding. Manufacturers test this using methods like pulling or peeling bonded specimens. They adhere to standards such as ASTM D429, ASTM D903, ISO 813, and ASTM D2228. I also pay attention to surface texture and tread patterns. These are vital for traction, ground protection, and wear life. Various patterns suit different operational needs. I also look for certifications like ISO:9001:2000 and ISO:14001 for manufacturing facilities. These indicate quality and environmental management. ISO9001 certification specifically assures quality manufacturing. ASTM standards serve as benchmarks for quality assurance. Regulatory frameworks in North America also enforce safety standards and certification requirements. These ensure rubber pads meet durability benchmarks.

Attachment Type Compatibility for Excavator Rubber Pads

I know the attachment type is crucial for proper fit and function. Different systems suit various operational needs.

| Attachment Type | Description |

|---|---|

| Clip-On | This type quickly attaches to steel tracks without extra hardware. It is ideal for temporary use or frequent surface changes. |

| Bolt-On | This type secures with bolts to the track shoe. It offers a durable solution for consistent work on surfaces needing protection. |

| Chain-On | This type integrates directly into the track chain. It provides a robust option for heavy-duty applications requiring high durability and stability. |

I always match the attachment type to my specific excavator and job requirements.

Excavator Model Fit for Rubber Pads

I ensure the rubber pads fit my excavator model perfectly. A precise fit prevents operational issues and maximizes pad effectiveness. I have used 700mm and 800mm pads on various common excavator models. These include the PC30, PC35, PC40, PC45, PC50, PC55, PC60, 75UU, and CAT305. Always confirm compatibility with your specific machine.

Environmental Resistance of Excavator Rubber Pads

I consider the environmental conditions where my excavators operate. The pads must withstand various elements. High-quality materials, as I mentioned, offer excellent heat resistance. This prevents degradation in hot climates. Abrasion resistance protects against wear from rough terrain and debris. I also look for resistance to chemicals and UV exposure. This ensures the pads maintain their integrity in diverse outdoor environments.

Warranty and Manufacturer Support for Excavator Rubber Pads

I always check the warranty and manufacturer support. A strong warranty indicates a manufacturer’s confidence in their product. For example, Superior Tire & Rubber Corp. offers a 2-year or 2000-hour wear-life guarantee for their CUSHOTRAC® ReDDi™ Track Pads. This ensures against bond or material failure. Good manufacturer support means I can get technical assistance and replacement parts when needed. This minimizes downtime and protects my investment.

The Advantage of Buying Wholesale Excavator Rubber Pads Direct from the Manufacturer

I consistently find significant advantages when I purchase directly from the manufacturer. This approach offers benefits beyond just the product itself. It impacts my budget, quality control, customization options, and operational efficiency.

Cost Savings and Wholesale Pricing for Excavator Rubber Pads

I always prioritize cost-effectiveness for my operations. Buying wholesale directly from the manufacturer provides substantial financial savings. Manufacturers offer tiered pricing structures. These structures reward larger orders with lower unit costs. I have observed this pattern repeatedly.

| Quantity Range | Unit Price (Example 1) | Unit Price (Example 2) |

|---|---|---|

| 1-99 pcs | $30 | N/A |

| 10-19 pcs | N/A | $6.90 |

| 20-49 pcs | N/A | $4.60 |

| 50-99 pcs | N/A | $4.14 |

| 100+ pcs | $8 | $3.91 |

This table clearly illustrates the price reduction. For instance, the unit price can drop from $30 for smaller quantities to $8 when I order 100 or more pieces. Another example shows a reduction from $6.90 per unit for 10-19 pieces down to $3.91 per unit for orders of 100 or more. These examples demonstrate substantial price decreases with increased order volume. This direct purchasing model eliminates intermediary markups. It allows me to allocate my budget more efficiently.

Quality Assurance and Control for Excavator Rubber Pads

I value consistent quality. Manufacturers ensure quality control through rigorous processes and certifications. They build pads using industry-leading rubber technology. Extensive engineering experience backs these products. Each pad undergoes rigorous quality control. This guarantees consistent performance and durability. Furthermore, manufacturing facilities are ISO:9001:2000 and ISO:14001 certified. These certifications indicate adherence to international quality management and environmental management standards. Quality control is also ensured by using superior rubber compounds. These compounds are designed for long-lasting durability. I trust the product when I know it comes directly from a certified source.

Customization Options Available for Excavator Rubber Pads

I often require specific solutions for unique job sites. Direct manufacturers offer extensive customization options. This goes beyond standard tread patterns. The effectiveness of rubber tracks depends on the quality of their components. Fortis HD, for example, uses premium natural rubber with additives. This produces a fine-tuned rubber compound for enhanced longevity. Their tracks are also thicker than OEM. This increases resistance to puncture, cuts, and friction degradation.

I can also choose from a variety of tread patterns:

- Block Tread: This is the most common. It works well in various conditions like gravel, finished lawns, sand, clay, asphalt, mud, and heated paved surfaces. It features large block-shaped pads in straight or staggered arrangements.

- Straight Bar Tread: This features slimmer pads. It offers excellent traction, a smooth ride, and dependable dirt compaction. It is ideal for muddy or wet surfaces. It maximizes traction and reduces the risk of getting stuck. It has a lower durometer rating. It is less likely to shred or tear turf.

- Multi-Bar: This provides high-performance traction and durability in muddy, wet conditions. It features two rows of slim pads. It is an all-season pattern. It reduces wear and extends performance life on flat, hard surfaces. It works well for dirt, sand, and general construction.

- Standard C-Pattern: This is highly versatile. It offers traction and durability. It features two rows of C-shaped pads. It is great for working in mud and dirt.

- Premium C-Pattern: This features larger C-shaped pads. It provides excellent traction for mud, dirt, and rocky terrain. It works well in demolition applications.

- H-Pattern: This is useful for multiple applications and general use. Each pad resembles a sideways H. It gives excellent traction and minimizes vibration. It is suitable for general construction on concrete, mud, rock, or slopes.

- Zig-Zag: This has a stepped design. It offers improved cleanout, reduced vibration, and prevention of side-to-side sliding. It is best for snow removal or excessively wet and muddy work sites, clay, or slippery slopes.

- Hex: This features hexagon-shaped pads. It offers durability and versatility on gravel, sand, solid dirt, or turf. It provides a comfortable, smooth ride and leaves minimal markings on lawns. I avoid it in excessively wet conditions.

- Technology Design Formulation (TDF): This is a linear tread. It effectively grips snowy and icy surfaces rather than digging. It is ideal for snow removal or tasks in snowy conditions. It prevents slipping.

These options allow me to tailor the pads precisely to my operational needs.

Expert Support and Technical Assistance for Excavator Rubber Pads

I rely on expert advice. Buying direct gives me access to specialized knowledge. Manufacturers offer comprehensive technical support. BLS Enterprises, with over 39 years of experience, offers support to end-users, dealers, and manufacturers. They are recognized for their industry leadership. They provide a hassle-free warranty and excellent customer service. This indicates a commitment to assisting customers with their product needs. ConEquip Parts also provides technical support through their highly trained and knowledgeable staff and parts specialists. These experts accurately identify and supply the appropriate rubber track pads for specific requirements. They leverage their extensive knowledge of heavy equipment machines and access to manufacturers’ parts books. They also offer a full parts warranty. They emphasize excellent customer service with experienced parts specialists. This direct line to experts helps me make informed decisions and troubleshoot issues quickly.

Faster Delivery and Logistics for Excavator Rubber Pads

I appreciate efficiency in logistics. Purchasing directly from the manufacturer often results in faster delivery times. This is because I eliminate intermediaries in the supply chain. The manufacturer can process and ship orders more directly. This reduces lead times. It allows me to manage my inventory more effectively. I can get the parts I need when I need them. This minimizes downtime for my equipment.

Future Trends in Excavator Rubber Pads for 2026 and Beyond

I see exciting developments ahead for these essential components. Innovation drives progress in our industry.

Advanced Material Composites for Excavator Rubber Pads

I anticipate significant advancements in material science. Manufacturers are exploring new elastomers, polymers, and composite materials. These innovations create lighter, stronger pads. They improve fuel efficiency and operational effectiveness. Advanced synthetic rubber compounds offer superior resistance to abrasion and environmental factors. This ensures longer-lasting pads, even in heavy-duty applications. I expect composite materials and advanced bonding technology to improve overall strength and reliability. This allows pads to withstand harsh environments.

Smart Pad Technology Integration in Excavator Rubber Pads

I believe smart technology will revolutionize pad management. We will see embedded sensors monitoring wear patterns, temperature, and pressure distribution in real-time. This allows us to predict pad replacement needs with high accuracy. Pilot programs show smart systems can predict replacement needs with 92% accuracy. This reduces unplanned downtime by 38%. Sensor fusion technology, including load cell integration, will enhance monitoring capabilities.

Sustainability in Manufacturing Excavator Rubber Pads

I observe a growing focus on sustainability. Manufacturers prioritize eco-friendly and recyclable materials. They aim to reduce carbon footprints and minimize ecological harm. Innovations enhancing durability also contribute to waste reduction. This aligns with ESG-focused practices. I expect more bio-based composites and recycled materials. This makes pads tougher and more reliable while reducing environmental impact.

Increased Customization Demands for Excavator Rubber Pads

I foresee a rising demand for specialized designs. The market is growing, driven by construction and mining sectors. This growth fuels a focus on customizable solutions. We need pads tailored to specific operational needs. Product performance, cost-effectiveness, and compatibility influence purchasing decisions. I expect manufacturers to offer more options to meet diverse consumer preferences.

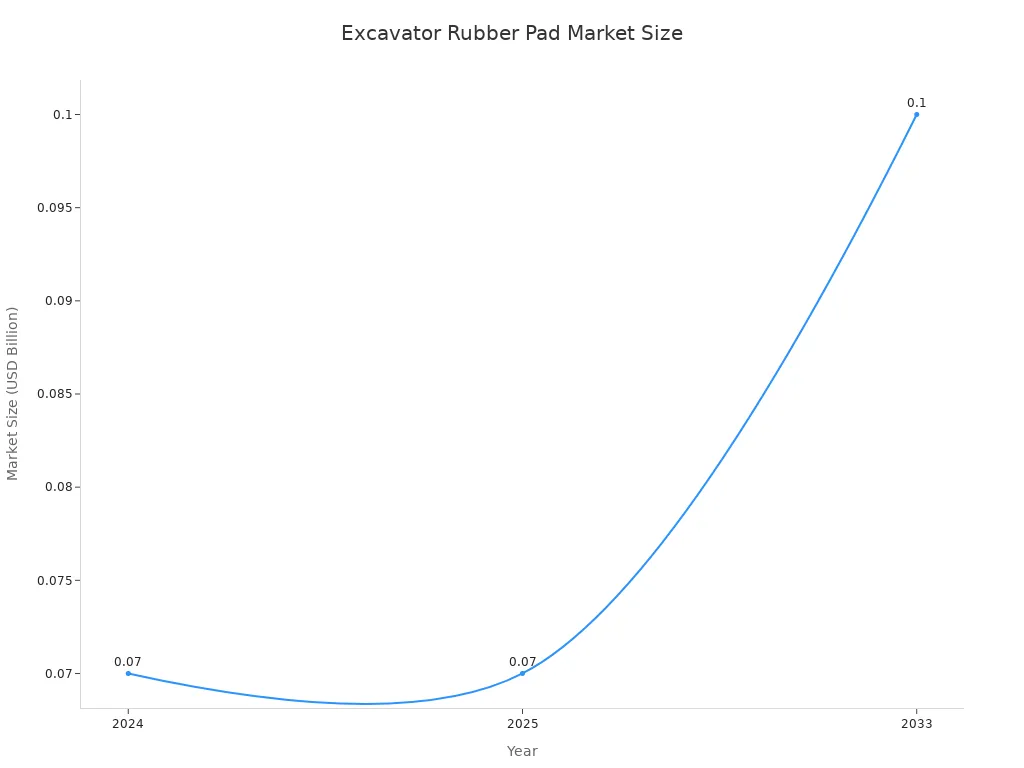

Global Market Expansion for Excavator Rubber Pads

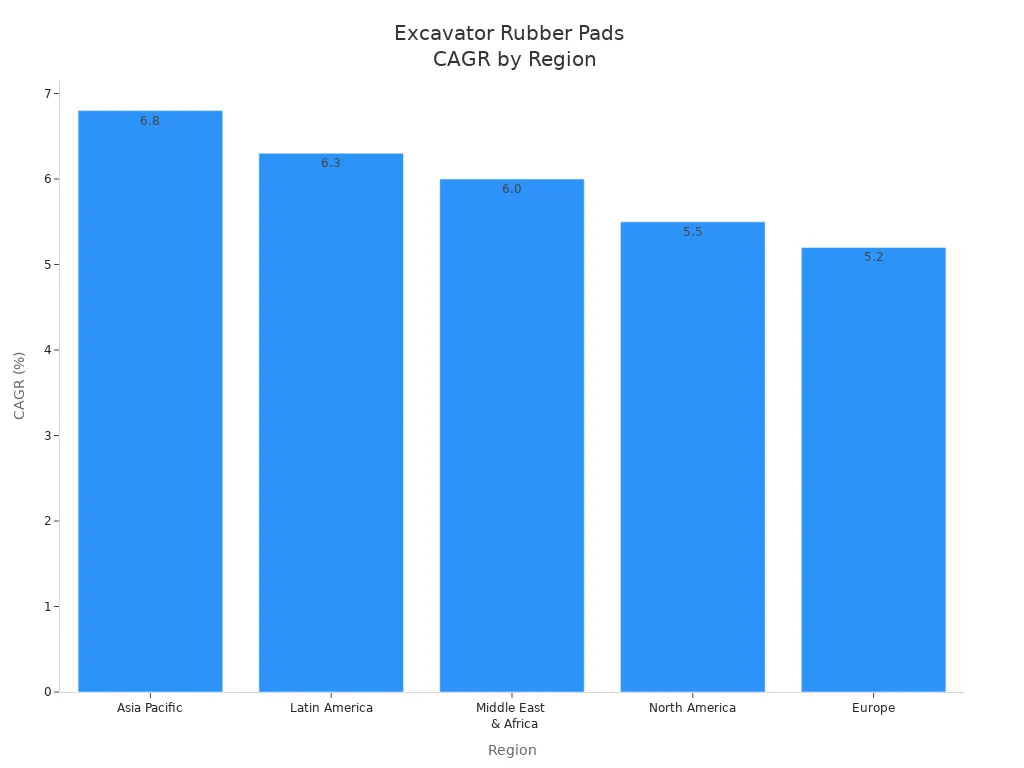

I anticipate continued global market expansion. The Asia Pacific region shows a 6.8% CAGR due to rapid infrastructure development. North America maintains consistent construction activities, with a 5.5% CAGR. Europe focuses on infrastructure maintenance and upgrades, showing a 5.2% CAGR. Latin America and the Middle East & Africa also demonstrate strong growth.

I believe investing in high-quality 700mm and 800mm rubber pads directly from a manufacturer ensures optimal performance. This provides protection and cost-effectiveness for my operations in 2026 and beyond. I make informed decisions to safeguard my equipment and work sites.

FAQ

How do 700mm excavator rubber pads and 800mm excavator rubber pads protect surfaces?

I use these pads to create a soft barrier. This barrier prevents damage to delicate surfaces. It safeguards asphalt, concrete, and lawns.

What are the main benefits of buying direct from the manufacturer?

I gain significant cost savings. I also get assured quality. Direct purchase provides customization options and expert support.

Can I customize 700mm and 800mm excavator rubber pads?

Yes, I can. Manufacturers offer various tread patterns. They also provide specific material compositions. This allows me to tailor pads for my unique job requirements.

Post time: Jan-07-2026