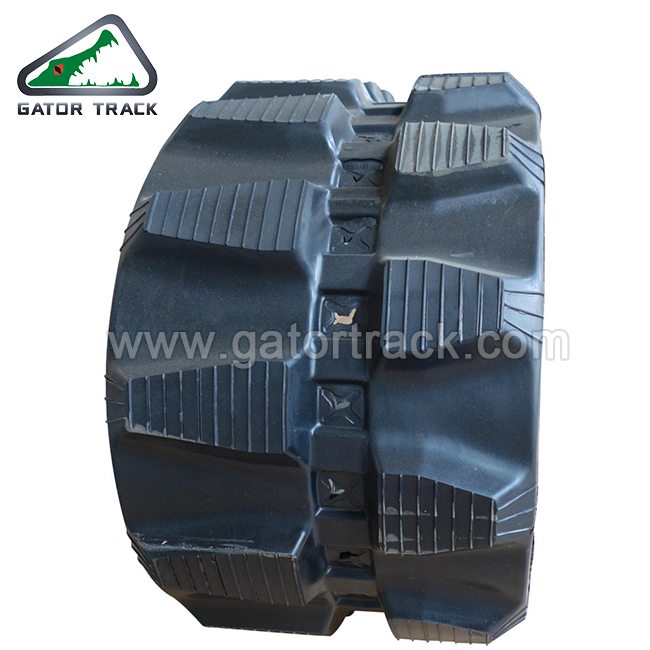

Top China Manufacturer of Bridgestone Mini Excavator Tracks

When I’m in need of top-quality tracks for Bridgestone mini excavators, I always turn to reliable options from China manufacturers. These tracks are designed to provide exceptional durability and performance, enhancing the operation of your excavator while minimizing downtime. With a keen focus on craftsmanship, they understand the unique demands of construction and landscaping applications. Whether you're involved in heavy-duty excavating or delicate site work, these tracks are engineered to fit perfectly and deliver impressive traction on various terrains. I've often found that choosing the right manufacturer can make all the difference, and the ones in China are known for their innovation and efficiency. Choosing the right tracks not just improves my machine's performance, but also ensures longevity. Make an informed decision for your Bridgestone mini excavator tracks, and watch how it elevates your operational efficiency to the next level!

Bridgestone Mini Excavator Tracks Manufacturer Application

When it comes to enhancing the performance of mini excavators, the choice of tracks plays a crucial role. High-quality tracks not only improve mobility and stability but also ensure efficiency and longevity in various working conditions. As the demand for durable and reliable mini excavator tracks grows globally, manufacturers are stepping up to provide excellent solutions tailored for diverse applications. Mini excavators are commonly used in construction, landscaping, and agricultural projects, and the right tracks can make a significant difference in operating costs and productivity. For instance, rubber tracks offer excellent grip and reduced ground pressure, making them ideal for soft or delicate surfaces. Steel tracks, on the other hand, are perfect for heavy-duty applications where durability is paramount, providing enhanced traction and longevity even in the most challenging environments. Selecting a manufacturer that understands these diverse needs is vital for procurement professionals. A reliable manufacturer not only ensures product quality but also offers customization options to fit specific requirements. By investing in high-performance tracks, operators can achieve better maneuverability and efficiency, ultimately leading to successful project outcomes and improved return on investment.

Bridgestone Mini Excavator Tracks Manufacturer Application

| Application | Excavator Model | Track Type | Material | Width (mm) | Height (mm) |

|---|---|---|---|---|---|

| Construction | BRJ-100 | Rubber | Synthetic Rubber | 300 | 100 |

| Demolition | BRJ-200 | Steel | High-Strength Steel | 320 | 110 |

| Landscaping | BRJ-150 | Rubber | Natural Rubber | 280 | 95 |

| Mining | BRJ-300 | Steel | Carbon Steel | 350 | 120 |

| Agricultural | BRJ-250 | Rubber | Nitrile Rubber | 310 | 105 |

Related Products