Rubber Pads for Steel Tracks to Colombia - China Manufacturer Solutions

When it comes to sourcing high-quality rubber pads for steel tracks, I know the importance of reliability and performance. I've worked closely with manufacturers in China that specialize in producing durable rubber pads, specifically designed to enhance the lifespan of your steel tracks in Colombia's diverse environments. These pads provide excellent cushioning and traction, reducing wear and tear while improving safety on the job. With a keen understanding of B2B needs, I can ensure that these products meet your exact specifications and requirements. Each rubber pad is crafted using top-notch materials, guaranteeing resistance to extreme conditions. Partnering with a trusted China manufacturer means not only quality assurance but also the ability to optimize costs, making it a better choice for your projects. Reach out today to find out how our rubber pads can transform your operations!

Rubber Pads For Steel Tracks to Colombia Guarantees Peak Performance Supplies the World\u2019s Top Brands

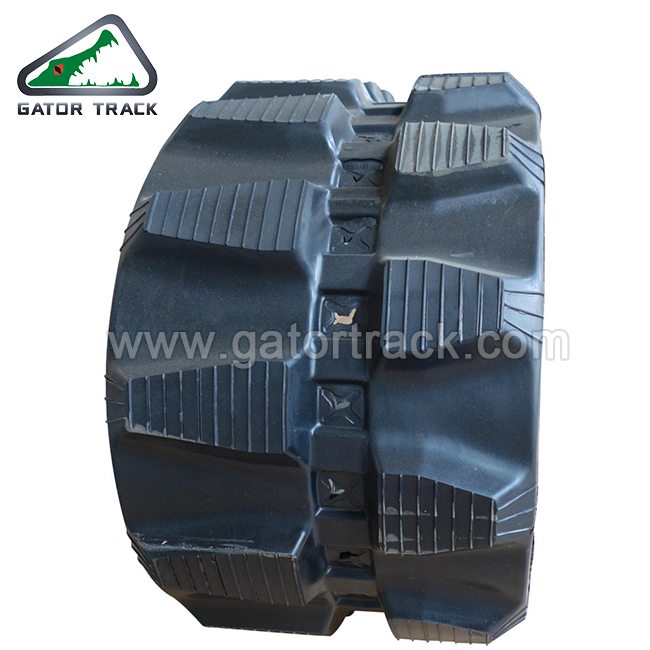

Rubber pads for steel tracks play a crucial role in enhancing performance and safety in various heavy machinery operating environments. As industries worldwide demand more from their equipment, the need for high-quality rubber pads has surged. These pads not only provide excellent shock absorption but also protect the underlying steel tracks from wear and tear, ensuring longevity and reliability of machinery used in construction, mining, and agriculture. Colombia has emerged as a significant player in the global market, with its rapidly expanding infrastructure projects and growing agricultural sector. By investing in innovative rubber pad solutions, companies can ensure their machinery operates at peak performance levels. The right rubber pads can improve traction and stability, reduce noise and vibration, and ultimately enhance operational efficiency, which is essential for winning contracts and improving overall profitability. Global buyers can benefit immensely from sourcing top-grade rubber pads tailored to their specific machinery requirements. By choosing high-performance rubber solutions, businesses can not only extend the lifespan of their equipment but also ensure they remain competitive in an increasingly demanding marketplace. Adopting advanced materials and technologies in rubber pad manufacturing guarantees optimal function and user satisfaction, making it a wise investment for any organization looking to maximize performance and minimize downtime.

Rubber Pads For Steel Tracks to Colombia Guarantees Peak Performance Supplies the World’s Top Brands

| Type | Material | Dimensions (mm) | Weight (kg) | Color |

|---|---|---|---|---|

| Standard Pad | Rubber | 200 x 300 x 50 | 1.5 | Black |

| Heavy Duty Pad | Reinforced Rubber | 250 x 350 x 60 | 2.0 | Dark Gray |

| Vibration Absorption Pad | Natural Rubber | 220 x 320 x 55 | 1.8 | Green |

| Custom Pad | Synthetic Rubber | Made to Order | Varies | Varies |

Related Products