Snow Rubber Tracks glide over snowy fields like a sled on a perfect winter day. They spread out the weight, so vehicles leave behind smooth, gentle trails instead of deep ruts. Their clever design keeps the snow looking fresh and protects what lies underneath.

Key Takeaways

- Snow rubber tracks spread vehicle weight over a wide area, reducing pressure on snow and preventing deep ruts or damage.

- Their flexible rubber design improves grip and smooth movement, helping vehicles avoid slipping and protecting snow surfaces.

- Compared to tires and metal tracks, snow rubber tracks offer better traction, longer life, less maintenance, and keep snow looking fresh.

How Snow Rubber Tracks Minimize Surface Damage

Wide Surface Area and Even Weight Distribution

Snow Rubber Tracks look like giant belts wrapped around a vehicle’s wheels. These tracks stretch out wide, almost like a snowshoe for machines. When a vehicle rolls over snow with these tracks, it spreads its weight over a much bigger area than regular tires. This means the snow doesn’t get squished down into deep ruts. Instead, the tracks leave behind a smooth, gentle path.

Tracked vehicles, even the really heavy ones, put less pressure on the ground than cars with regular tires. For example, a tank with tracks presses down with about 15 psi, while a car tire can push down with 28 to 33 psi. That’s a big difference! The wide surface area of Snow Rubber Tracks helps vehicles glide over soft snow, mud, or even sand without sinking or getting stuck.

Snow Rubber Tracks act like a gentle giant, carrying heavy loads but leaving only a whisper of a footprint behind.

- Snow Rubber Tracks have a wide surface area that distributes the weight of machinery more evenly.

- This larger contact area reduces ground pressure, which helps minimize soil compaction.

- Reduced ground pressure is great for protecting sensitive terrains and keeping snow surfaces looking fresh.

Flexible Rubber Material and Low Ground Pressure

Rubber is a superhero when it comes to flexibility. Snow Rubber Tracks bend and flex as they move, hugging the ground and absorbing bumps. This flexibility means the tracks don’t dig into the snow or tear it up. Instead, they glide smoothly, keeping the snow surface intact.

Low ground pressure is the secret weapon here. Because the tracks are wide and made of rubber, they press down softly on the snow. This gentle touch keeps the snow from getting packed too tightly or damaged. Farmers, snowmobile riders, and even rescue teams love this feature because it helps them travel across snowy fields without leaving a mess behind.

Product Features of Snow Rubber Tracks

Snow Rubber Tracks come packed with features that make them perfect for snowy adventures. They use a mix of rubber and strong skeleton materials, giving them both strength and flexibility. The walking system on these tracks runs quietly and with little vibration, so the ride feels smooth and comfortable. Drivers can count on advanced electrical instruments and a complete machine status monitoring system to keep everything running safely.

Here’s a quick look at what makes these tracks special:

| Feature | Benefit |

|---|---|

| Wide, flexible rubber surface | Even weight distribution, less damage |

| Low noise and vibration | Comfortable ride |

| All-terrain performance | Handles snow, mud, and more |

| Reliable monitoring systems | Keeps drivers informed and safe |

Snow Rubber Tracks work best in temperatures from -25°C to +55°C. They handle high-speed transfers and tough winter conditions with ease. Their design helps vehicles move smoothly over snow, protecting both the snow and what’s underneath.

Enhanced Traction and Real-World Benefits of Snow Rubber Tracks

Preventing Slippage, Digging, and Rutting

Snow Rubber Tracks grip the snow like a mountain goat on a rocky cliff. Their wide, directional treads bite into the snow, giving vehicles up to 25% better traction than regular tires. Operators notice that these tracks keep machines from slipping, digging, or leaving deep ruts. The secret lies in their design. Directional treads push snow away, while the flexible rubber hugs the ground.

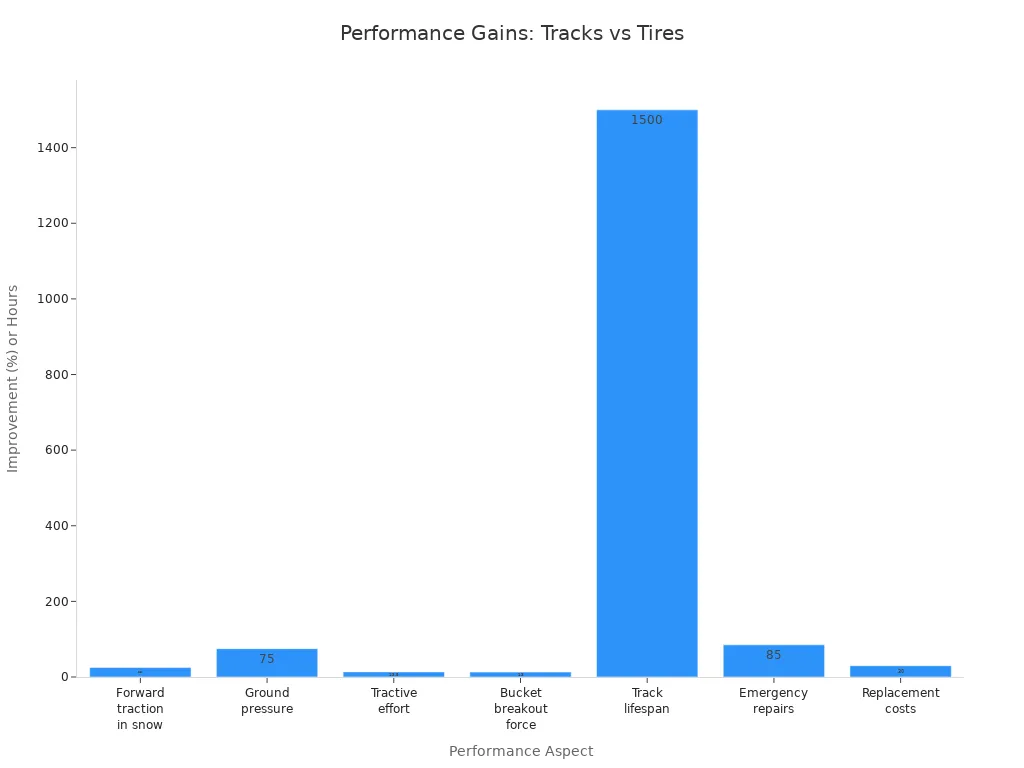

Here’s a quick look at how they stack up:

| Performance Aspect | Improvement / Benefit |

|---|---|

| Forward traction in snow | Up to 25% better traction with directional treads |

| Ground pressure | Reduced by up to 75%, lowering soil compaction and rutting |

| Tractive effort | Increased by +13.5%, improving pushing power |

| Bucket breakout force | Increased by +13%, enhancing digging capability |

| Track lifespan | 1,000–1,500 hours, leading to fewer replacements |

| Emergency repairs | Up to 85% fewer, reducing downtime |

| Replacement costs | Up to 30% lower than tires |

Operators say Snow Rubber Tracks spread weight so well that machines glide over snow instead of sinking.

Comparison with Metal Tracks and Traditional Tires

Snow Rubber Tracks outshine metal tracks and regular tires in winter. Metal tracks can chew up snow and leave scars, while tires often spin and dig holes. Rubber tracks, on the other hand, use advanced materials like reinforced steel cables and special rubber compounds. These features help them last longer and grip better.

Check out this comparison:

| Aspect | OTT Rubber Tracks | Dedicated Track Equipment |

|---|---|---|

| Traction Improvement | 40-60% increase over standard tires in wet/snow | Maximum traction and stability |

| Surface Protection | Non-marking rubber protects asphalt, concrete | N/A |

| Installation Time | Quick (30-90 minutes), minimal downtime | N/A |

| Initial Investment | 60-70% less than dedicated track machines | High capital investment |

| Equipment Compatibility | Retrofit existing equipment (skid steers, loaders) | Purpose-built machines |

| Operational Flexibility | High, suitable for mixed terrain | Limited versatility |

| Maintenance Complexity | Lower, regular inspection and tension adjustment | Higher maintenance and repair costs |

| Payback Period | Typically 6-12 months through reduced downtime and costs | N/A |

Preserving Snow Quality and Reducing Maintenance

Snow Rubber Tracks keep snow looking fresh and smooth. They don’t leave behind ugly ruts or packed-down patches. This matters for ski resorts, city parks, and anywhere people want perfect snow. Heavy Duty Bar tread tracks work best for deep snow, while Zig-Zag treads handle lighter jobs like snow removal in parking lots.

People use these tracks for:

- Snow removal in cities and towns

- Smoothing trails for snowmobiles and skiers

- Keeping construction sites safe in winter

Machines with Snow Rubber Tracks need fewer repairs and last longer. That means less time in the shop and more time working. Snow stays pretty, and everyone wins.

Winter machines with rubber tracks turn snowy fields into smooth highways. Experts point out that:

- Staggered tread patterns keep vehicles steady on ice.

- Siping boosts grip on slippery snow.

- Multi-bar and C-lug tracks shine in deep drifts. Choosing the right track keeps snow surfaces safe and beautiful.

FAQ

Do snow rubber tracks work on icy surfaces?

Snow rubber tracks grip ice like a penguin’s feet. They keep vehicles steady and safe, even when the world turns into a giant skating rink.

Tip: Choose tracks with siping for extra grip on slick ice!

Can you use snow rubber tracks all year round?

Yes! Snow rubber tracks handle mud, sand, and grass. They turn any season into adventure season. Just clean them after use for a longer life.

How do you care for snow rubber tracks?

Keep tracks clean. Remove salt, oil, and debris. Check for sharp objects. Regular care keeps tracks rolling smoothly and looking sharp.

Post time: Aug-05-2025