Mini Skid Steer Rubber Tracks help machines move easily over soft or muddy ground. These tracks give better traction and help keep the equipment stable. Farmers, landscapers, and builders often use these tracks to work more safely and finish jobs faster.

Key Takeaways

- Mini skid steer rubber tracks improve machine traction and stability on soft or uneven ground, helping operators work safely and efficiently.

- These tracks use strong rubber and steel materials that resist wear, tear, and harsh conditions, making them durable and long-lasting.

- Regular maintenance, like checking tension and cleaning, extends track life and reduces costly repairs, saving time and money.

Mini Skid Steer Rubber Tracks: Features and Benefits

Materials and Construction

Mini Skid Steer Rubber Tracks use advanced materials to deliver strength and flexibility. Manufacturers combine natural rubber for elasticity and tear resistance with synthetic rubbers like SBR for abrasion protection and temperature stability. These tracks often include steel core technology, where continuous steel cords or all-steel chain links add strength and help the track keep its shape under heavy loads. Some brands use drop-forged steel parts and special adhesives to create a strong bond inside the track, making it more robust and reliable.

Hybrid rubber tracks now resist extreme temperatures, UV rays, and harsh chemicals. This means they last longer and perform better in tough environments.

A typical track consists of several layers:

- Outer rubber for grip and wear resistance

- Reinforced steel cords for strength

- Inner rubber for flexibility and bonding

| Material Component | Function |

|---|---|

| Natural/Synthetic Rubber | Elasticity, abrasion, and tear resistance |

| Steel Cords/Links | Structural strength and shape retention |

| Adhesive Bonding | Durability and internal cohesion |

Our Mini Skid Steer Rubber Tracks use specially formulated rubber compounds that resist cutting and tearing. The all-steel chain links fit machines precisely, ensuring smooth operation and stability.

Tread Patterns and Design

Tread patterns play a big role in how Mini Skid Steer Tracks perform. There are four main tread types: lateral, directional, block, and hybrid. Lateral treads have lugs that run across the track, which helps the machine turn smoothly and reduces turf damage. Directional treads point forward and give better grip in mud or soft soil. Block treads work well on mixed surfaces, while hybrid designs combine features for use on different terrains.

Studies show that lateral tread patterns can reduce turf damage by up to 40% and improve maneuverability by up to 35%. Landscapers and builders often choose these patterns to protect lawns and finish jobs faster. Multi-bar tread designs also reduce vibration, making the ride smoother and more comfortable for the operator.

Data shows that lateral tread designs lower fuel use by 3-7% and increase resistance to sideways slipping by up to 60%. This means less ground disturbance and better control.

Traction, Stability, and Surface Protection

Mini Skid Steer Rubber Tracks give machines better traction and stability, especially on soft, muddy, or uneven ground. The wide surface area spreads the machine’s weight, lowering ground pressure and helping the loader avoid sinking or slipping. This protects the surface and keeps the machine steady.

| Performance Metric | Improvement / Value | Benefit / Explanation |

|---|---|---|

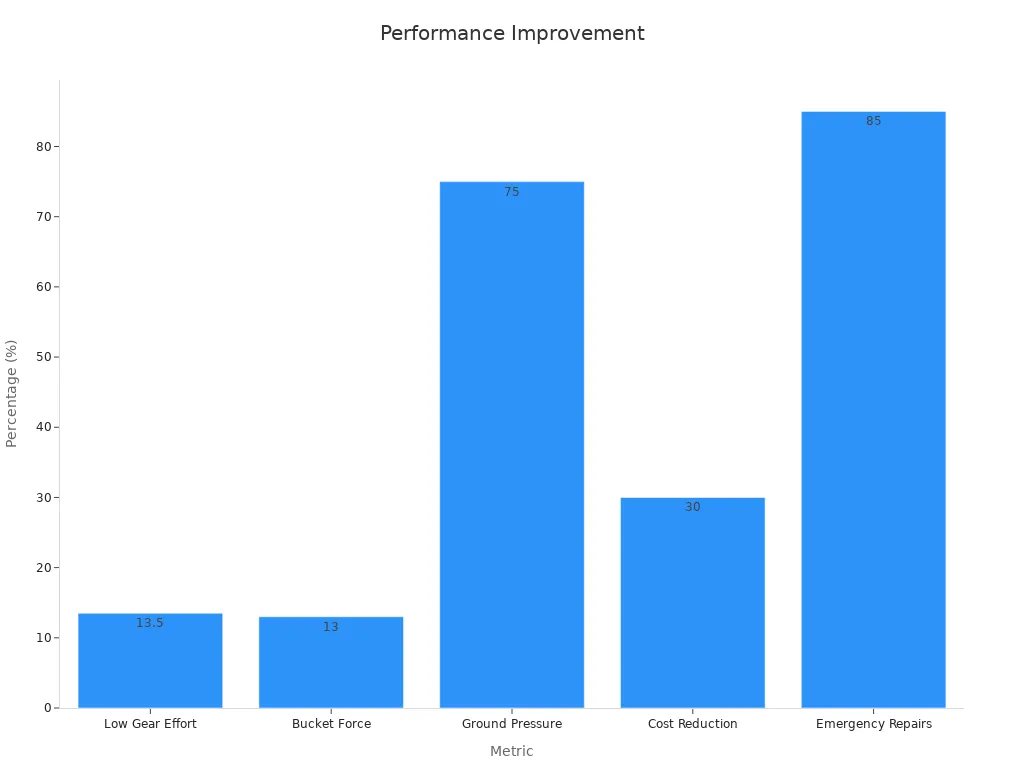

| Tractive effort (low gear) | +13.5% | Increased pushing power |

| Bucket breakout force | +13% | Enhanced digging and handling |

| Ground contact points | 48 | Smoother, lighter footprint |

| Ground pressure | Up to 75% less | Less soil compaction and ground disturbance |

| Emergency repairs reduction | 85% less | Fewer breakdowns and downtime |

Field tests and engineering studies confirm that these tracks improve turning precision, reduce slippage, and protect sensitive surfaces like turf. Operators can work on slopes and rough terrain with more confidence and less risk of getting stuck.

Durability and Longevity

Durability is a key benefit of Mini Skid Steer Rubber Tracks. Manufacturers test these tracks to meet strict quality standards, including ISO certifications. Features like thick, gouge-resistant carcasses and aramid fiber layers help prevent stretching and tearing. Premium tracks use higher carbon black content for better heat and gouge resistance.

Many tracks last between 1,000 and 1,500 hours, which is much longer than standard tires or lower-grade tracks. Some brands report up to 30% lower replacement costs and 85% fewer emergency repairs.

Proper maintenance and choosing the right track for the job can extend service life even further. Our tracks use drop-forged steel parts and a unique adhesive process, creating a stronger bond and making the track more reliable for long-term use.

Choosing and Comparing Mini Skid Steer Rubber Tracks

Rubber Tracks vs. Tires and Steel Tracks

When choosing between rubber tracks, tires, and steel tracks for a mini skid steer, it helps to look at how each option performs in real-world jobs. Rubber tracks stand out for their ability to spread the machine’s weight over a larger area. This reduces ground pressure and helps protect grass, soil, and other delicate surfaces. Many landscaping and agricultural projects need this kind of surface protection.

- Rubber tracks absorb shocks and reduce vibrations better than steel tracks or tires. Operators feel less tired after long workdays.

- They run more quietly than steel tracks, which makes them a good choice for work in neighborhoods or near schools.

- Rubber tracks offer better flotation in mud or soft ground, so machines can work longer during wet seasons.

- Advanced rubber tracks use blends of natural and synthetic rubber, steel cords, and anti-corrosion treatments. These features help the tracks last longer—often over 1,000 hours of use.

Market data shows that rubber tracks make up about 40% of the demand for compact construction equipment. Regular rubber tracks hold over 70% of the market because they are versatile, cost-effective, and durable. Newer designs, such as non-marking and reinforced rubber tracks, last even longer and work well in more places. Many owners prefer rubber tracks because they avoid flat tires and reduce downtime, especially in demolition and forestry work.

Rubber tracks also help keep the undercarriage in better shape by absorbing impacts, which lowers repair costs and extends the life of the machine.

Matching Tracks to Application and Terrain

Selecting the right track for skid steer depends on the job and the ground conditions. Different tread patterns and track widths work best for different tasks.

| Factor | Description & Impact | Application/Terrain Example |

|---|---|---|

| Terrain Type | Determines tread pattern and track width needed | Road surfaces, loose terrain, mud, snow, hard surfaces |

| Lug-to-Void Ratio | High ratio increases contact patch for traction on hard surfaces | Road surfaces |

| Groove Width | Wide grooves needed to pack loose materials for traction | Loose terrain (sand, gravel, snow) |

| Track Width | Influences flotation and ground pressure; wider tracks reduce pressure and increase flotation | Wide tracks for loose terrain; narrow tracks for hard ground |

| Track Width Ranges | Narrow: <12 in (305 mm); Standard: 12-18 in (305-457 mm); Wide: 18-24 in (457-610 mm) | General purpose, material handling, demolition, landscaping |

| Example: John Deere 317G | Operational weight: 8,423 lb; Narrow track contact area: 639.95 in²; Wide track contact area: 800 in² | Narrow tracks exert 25% more ground pressure than wide tracks |

| Project Length | Economy tracks for short-term/light use; Premium tracks for heavy-duty/long-term use | Rugged economy vs. premium track lines |

- Multi-bar tread patterns give strong grip on soft or loose ground and clean themselves to prevent mud buildup.

- C-Lug patterns provide traction in many directions and reduce vibration, making them good for mixed terrain.

- Block treads work best on hard surfaces and help lower vibration and ground pressure.

Operators should measure track width, pitch, and link count to ensure a proper fit. Fitment guides help match tracks to specific skid steer models. For construction, tracks designed for debris and mixed surfaces work best. In agriculture, tracks that reduce soil compaction and improve flotation are ideal. Landscaping jobs often use turf-friendly tracks with gentle tread patterns.

A 9-inch wide all-terrain track improves traction and ride quality, helping the machine move safely on slopes, snow, and technical ground.

Maintenance Tips and Replacement Signs

Proper care helps Skid Loader Tracks last longer and perform better. Operators can follow these simple steps to extend track life:

- Inspect and adjust track tension regularly.

- Avoid running the machine over sharp or abrasive surfaces like rocks, asphalt, or scrap metal.

- Clean tracks to remove debris, oil, and chemicals.

- Store equipment indoors to protect tracks from sun damage.

- Run the engine from time to time during storage to keep the rubber flexible.

Signs that tracks need replacement include:

- Dry-rotting or visible cracks in the rubber.

- Worn sprockets or missing lugs.

- Loose track tension that cannot be fixed by adjustment.

Customer stories show that high-quality rubber tracks, combined with regular maintenance, lead to longer track life and better machine performance. Operators report fewer breakdowns and less downtime when they follow a good maintenance routine.

Regular care and the right track choice help operators get the most out of their mini skid steer, saving money and time in the long run.

Mini Skid Steer Rubber Tracks offer strong durability, stability, and surface protection. When choosing tracks, users should:

- Check ground conditions and track type.

- Follow daily maintenance routines.

- Replace worn tracks quickly.

Customer feedback shows that proper care extends track life and improves machine performance.

FAQ

How often should operators check mini skid steer rubber tracks?

Operators should inspect tracks before each use. Regular checks help spot damage early and keep the machine running safely.

Tip: Look for cracks, cuts, or loose tension during every inspection.

Can mini skid steer rubber tracks be used on snow or ice?

Yes, these tracks work well on snow and ice. The tread design gives extra grip and helps prevent slipping.

What makes your rubber tracks different from standard tracks?

Our tracks use special rubber compounds and all-steel chain links. This design improves durability, fit, and smooth operation for many job sites.

Post time: Jul-02-2025