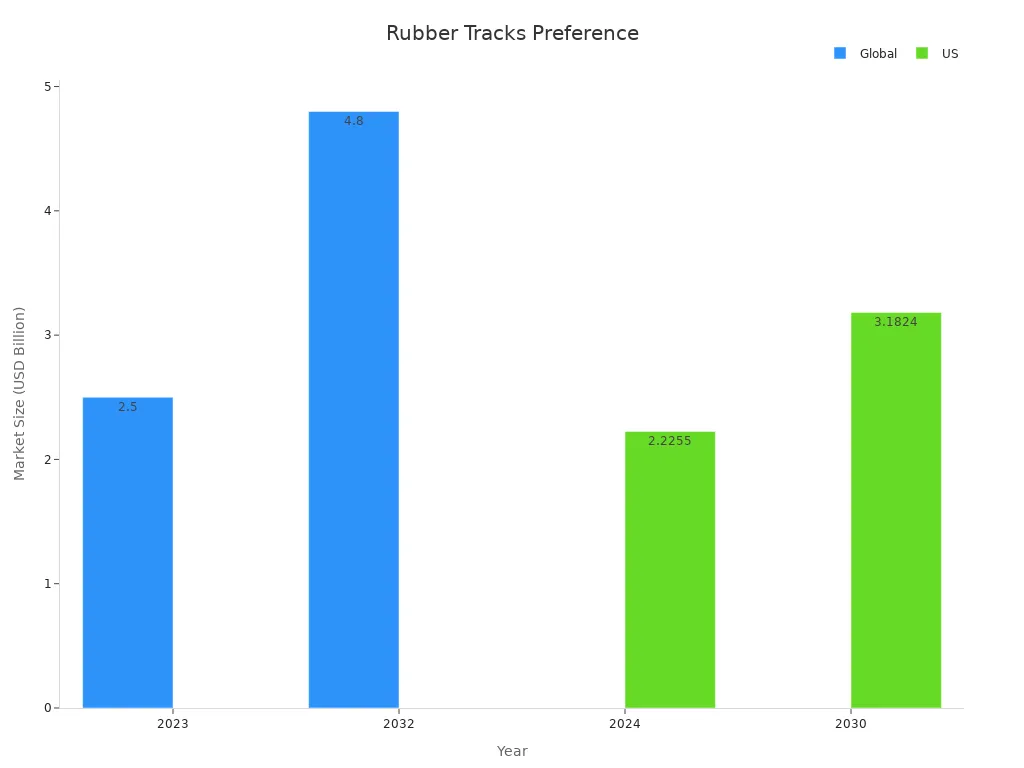

Rubber Excavator Tracks transform modern construction. They protect surfaces, boost maneuverability, and cut noise. Many companies choose them for cost savings and easy installation. The market for these tracks continues to grow, reaching $2.5 billion in 2023.

Key Takeaways

- Rubber excavator tracks protect surfaces by spreading weight evenly, reducing ground damage and noise, making them ideal for sensitive environments like urban areas and landscapes.

- These tracks boost machine performance with better traction, smoother rides, and easier installation, helping operators work more efficiently and comfortably across various terrains.

- Proper maintenance, including daily inspections and careful driving, extends rubber track life significantly, lowering costs and downtime for equipment owners.

Rubber Excavator Tracks vs. Steel Tracks

Material and Design Differences

Rubber Excavator Tracks and steel tracks each bring unique qualities to construction equipment. Rubber tracks use elastic, wear-resistant rubber that wraps around the undercarriage. This design isolates metal from direct contact with the ground, protecting both the track and the surface below. Steel tracks, on the other hand, rely on heavy-duty metal links and plates. These provide strength and durability for demanding environments.

The difference in materials leads to distinct mechanical properties. Recent research highlights how rubber and steel affect strength and flexibility:

| Mechanical Property | Rubber Content Effect | Steel Fiber Content Effect |

|---|---|---|

| Compressive Strength | Medium decrease | Medium increase |

| Tensile Strength | Medium decrease | Large increase |

| Modulus of Rupture | Medium decrease | Large increase |

Rubber content tends to reduce compressive and tensile strength, while steel fibers boost these properties. This means steel tracks excel in raw strength, but rubber tracks offer flexibility and surface protection. The elastic nature of rubber also helps absorb shocks and vibrations, making it ideal for sensitive environments.

Performance in Construction Applications

Construction sites demand equipment that can adapt to changing conditions. Rubber Excavator Tracks shine in urban and landscaped areas. Their soft, flexible material reduces ground damage and keeps surfaces intact. Operators notice less noise and vibration, creating a more comfortable work environment.

Steel tracks perform best on rough, rocky terrain. Their rigid structure handles heavy loads and sharp debris. However, they can leave deep marks on finished surfaces and generate more noise.

Rubber Excavator Tracks have gained popularity in many industries, including agriculture, mining, and forestry. They lower total ownership costs by about 25% in high-use scenarios. This cost advantage comes from easier maintenance and longer service life when operators follow best practices. Regular inspections, proper tension, and clean worksites help extend the lifespan of rubber tracks. Driver training also plays a key role in preventing damage.

Tip: Rubber Excavator Tracks are easy to install and block track segments protect the ground, making them a smart choice for projects where surface preservation matters.

Both track types have their place, but the rise of rubber tracks shows a shift toward versatility, cost savings, and environmental care. Modern equipment owners see these benefits and choose rubber tracks to meet new challenges with confidence.

Advantages of Rubber Excavator Tracks

Surface Protection and Reduced Ground Damage

Rubber Excavator Tracks protect the ground better than traditional alternatives. Their elastic rubber material spreads the machine’s weight over a larger area. This reduces ground pressure and prevents deep ruts or soil compaction. Studies show that rubber tracks can reduce rut depth by up to three times compared to conventional tracks. Operators see less damage on lawns, golf courses, and sensitive landscapes. Laboratory tests confirm that these tracks lower sinkage and keep surfaces smooth, even on soft or wet soils. This makes them ideal for projects where surface preservation matters most.

Note: Rubber tracks are especially effective on grass, mud, and sand, where soil drainage and surface appearance are important.

Enhanced Maneuverability and Versatility

Machines equipped with rubber tracks move with confidence across many terrains. These tracks provide strong traction and stability on slopes, muddy fields, and uneven ground. Operators experience up to 30% higher productivity in muddy regions. Wider tracks can lower ground pressure by as much as 75%, making it easier to work on delicate surfaces. Specialized tread designs help prevent tipping and improve grip. Rubber tracks also allow for zero-turn capability, letting machines rotate in place for precise movement. Farmers and contractors call them “all-terrain heroes” because they perform well on everything from construction sites to snowy roads.

- Key benefits include:

- Superior grip on mud, rocks, and sand

- Reduced slippage, improving fuel efficiency

- Smoother ride and better operator comfort

- Versatility for use on loaders, dumpers, and even robots

Lower Noise and Vibration Levels

Rubber Excavator Tracks create a quieter and more comfortable work environment. The rubber material absorbs vibrations and reduces noise, which benefits both operators and nearby communities. Acoustic tests show that embedded tracks with elastomeric materials can lower radiated noise by 3 to 6 decibels compared to traditional tracks. Increasing the elastic modulus of the pad further improves noise reduction. Operators notice less fatigue and stress during long workdays. This makes rubber tracks a smart choice for urban projects and sensitive environments where noise control matters.

| Track Type | Noise Reduction (dB) | Notes |

|---|---|---|

| Embedded Rubber | 3 – 6 | Lower radiated noise, smoother ride |

| Steel Track | 0 | Higher noise, more vibration |

Cost Efficiency and Maintenance Benefits

Rubber Excavator Tracks offer real savings for equipment owners. Their lower initial price makes them an attractive choice for many projects. The lighter weight and reduced rolling resistance improve fuel efficiency, especially on smooth or compacted surfaces. These tracks cause less ground disturbance, which means less money spent on repairing job sites. In urban and landscaping applications, operators see lower maintenance costs and longer service life. Premium rubber tracks can last between 1,000 and 1,500 hours, while standard tracks last 500 to 800 hours. With proper care, some rubber tracks reach up to 3,000 operating hours. The global market for mini excavator rubber tracks continues to grow, reflecting their cost-effectiveness and operational benefits.

Tip: Rubber Excavator Tracks are easy to install and maintain. Their design helps extend the service life of both the tracks and the machine.

Technological Innovations in Rubber Excavator Tracks

Advances in Rubber Compound Durability

Manufacturers continue to push the boundaries of durability in Rubber Excavator Tracks. They use eco-friendly natural oils, such as neem and soybean, to make rubber compounds tougher and more resistant to wear. Nanofillers like graphene and silica help the rubber last longer by improving how the materials mix together. Modified copolymers reduce cracks and make the tracks stronger over time. New mixing methods and bio-based elastomers also help the rubber stay strong while using less energy. Composite Rubber Tracks combine rubber with carbon nanotubes, carbon fiber, and steel cords. These tracks can last up to 5,000 kilometers, much longer than traditional steel tracks. Maintenance becomes easier and faster, and the risk of losing a track drops by 87%.

Integration with Modern Equipment Systems

Rubber Digger Tracks now fit seamlessly with today’s advanced machines. Track systems can last between 800 and 1,500 hours, depending on the job. Forestry work usually sees about 800 to 1,000 hours, while lighter tasks like trenching can reach up to 1,500 hours. Some compact excavator tracks weigh as much as 900 pounds, showing their strength and reliability. These numbers give equipment owners confidence in their investment. Modern tracks help machines work longer and more efficiently, making every project smoother.

Adaptation to Urban and Sensitive Environments

Construction companies see big benefits when using these tracks in cities and delicate areas. One firm increased track life from 500 to over 1,200 hours, cutting emergency repairs by more than 80%. Reinforced sidewalls and self-cleaning treads help machines move through mud and soft ground without getting stuck. Rubber track pads spread weight evenly, protecting roads and sidewalks. Noise drops by up to 20%, which keeps neighborhoods quieter and happier. Smart tracks with sensors warn operators before problems happen, reducing downtime. Using recycled rubber also helps the planet, proving that innovation can protect both people and the environment.

Practical Considerations for Using Rubber Excavator Tracks

Product Features and Installation Benefits

Rubber tracks bring powerful advantages to modern equipment. Their design increases ground contact, which boosts traction and stability on rough or soft terrain. Operators see less slippage and better safety. These tracks spread the machine’s weight over a larger area, protecting lawns, roads, and sensitive surfaces from damage. Advanced rubber compounds resist punctures, abrasions, and harsh weather, so machines keep working longer with less downtime.

Key features and benefits include:

- Superior traction and stability on uneven ground

- Reduced soil compaction and ground pressure

- High load-bearing capacity for heavy jobs

- Long-lasting materials that resist wear and chemicals

- Improved fuel efficiency from better traction

- Quieter operation for operator comfort

Installation is straightforward. Experts recommend preparing the machine on a level surface, lowering the undercarriage, and releasing track tension. Old tracks come off with simple tools. New tracks fit easily when aligned with sprockets and rollers. Proper tension prevents sagging and keeps the machine running smoothly. Operators test for unusual sounds and adjust as needed.

Customers report less downtime and longer tread life, even in tough environments like quarries and swamps. These tracks prove reliable for both heavy-duty and rental equipment.

Usage Precautions and Best Practices for Longevity

Proper care extends the life of rubber tracks. Field data shows that well-maintained tracks can last up to 5,000 hours, while neglected ones may wear out after only 500 hours.

| Maintenance Condition | Average Track Lifespan (hours) |

|---|---|

| Neglected / Poorly Maintained | 500 |

| Typical Maintenance | 2,000 |

| Well Maintained (Regular Inspection) | Up to 5,000 |

Operators should:

- Inspect tracks daily for cracks, cuts, or worn tread.

- Choose tracks that match the job and terrain.

- Fit tracks accurately and check tension often.

- Clean tracks and remove debris after each use.

- Lubricate grease points and inspect drive wheels.

- Train all operators on careful driving and turning.

- Replace tracks when tread is worn or damaged.

Tip: Smooth driving and regular cleaning help prevent early wear. Following these steps inspires confidence and keeps machines working at their best.

Future Trends for Rubber Excavator Tracks

Emerging Materials and Smart Technologies

The future of excavator tracks shines with innovation. Manufacturers now use advanced materials like synthetic rubbers, polymer blends, and hybrid systems. These new compounds boost durability, flexibility, and weather resistance. Nanotechnology and self-healing polymers help tracks last longer and recover from damage. Companies also add recycled and sustainable materials, supporting green construction goals.

Smart technologies change how operators care for their machines. Tracks with built-in sensors send real-time data about wear and performance. Artificial intelligence uses this data to predict maintenance needs and prevent breakdowns. Prefabricated modules make installation faster and more reliable. Advanced coatings improve grip and reduce abrasion, keeping machines safe and steady.

Operators feel empowered by these changes. They trust their equipment to work harder and last longer, even in tough conditions.

Market Growth and Industry Adoption

The global market for excavator tracks continues to expand. Recent reports show strong growth:

- The market reached USD 2.31 billion in 2024 and could climb to USD 3.92 billion by 2033, with a 6.1% annual growth rate.

- Construction holds a 51% share of the market, thanks to high demand for excavators and compact loaders.

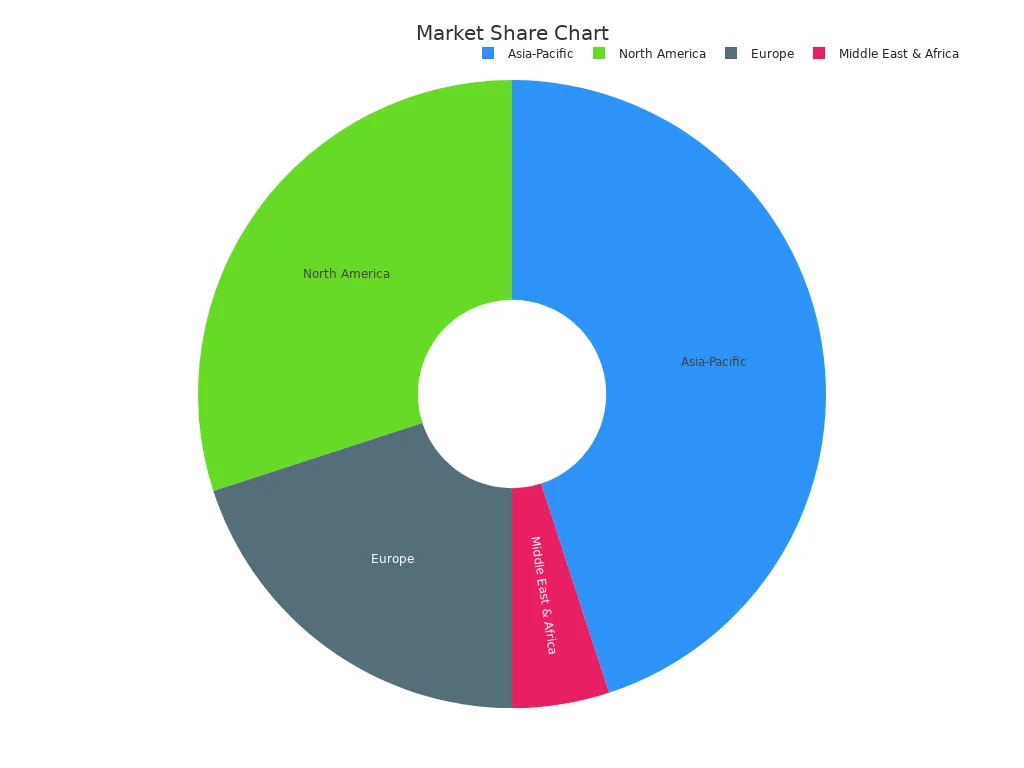

- Asia-Pacific leads with rapid industrial growth and government support for new projects.

- The U.S. market expects to grow from USD 525.3 million in 2024 to USD 736.7 million by 2030.

A table highlights more trends:

| Aspect | Details |

|---|---|

| Projected Value 2033 | USD 2,976.3 million |

| Fastest Growth Region | Asia-Pacific (45% market share) |

| Key Drivers | Infrastructure, agriculture, eco-innovation |

| Industry Impact | 25% longer lifespan, 40% recycled materials |

The industry moves forward with hope. New technology and strong demand inspire companies to create better, greener solutions for every job.

Excavator with Rubber Tracks inspire progress in construction. They deliver strong traction, lower costs, and protect surfaces. Operators see longer track life and fewer repairs.

- Tracks reduce ground damage and boost fuel efficiency.

- Real-world cases show longer seasons and higher productivity.

Staying informed about new features helps every team succeed.

| Benefit | Impact |

|---|---|

| Cost Savings | Fewer replacements, less downtime |

| Performance | Better traction, safer operation |

FAQ

How do rubber excavator tracks help protect the environment?

Rubber tracks reduce ground damage and noise. They help keep landscapes beautiful. Many companies use recycled materials, making every project greener and more sustainable.

Can operators install rubber excavator tracks easily?

Yes! Operators find installation simple and quick. The design allows for fast replacement. This saves time and keeps machines working longer.

What maintenance tips help rubber tracks last longer?

Operators should inspect tracks daily, clean them after use, and drive smoothly. These habits inspire longer track life and better performance every day.

Post time: Jul-01-2025