Rubber tracks for skid loader provide machines with superior grip and stability, especially on muddy or uneven terrain. Many operators report fewer breakdowns and extended track life when using rubber tracks for skid steer.

- Crews experience less downtime during bad weather thanks to the reliability of rubber tracks for skid steer.

- These tracks help prevent slipping, making work both safer and more productive.

- With rubber tracks for skid steer, turf remains protected, allowing jobs to be completed more efficiently.

Key Takeaways

- Rubber tracks improve skid steer traction and stability on soft, muddy, or uneven ground, making work safer and more efficient.

- Choosing the right tread pattern and track width helps protect the ground, boosts machine performance, and reduces downtime.

- Regular inspection, cleaning, and proper tension keep rubber tracks lasting longer and reduce repair costs.

Key Features of Rubber Tracks for Skid Steer

Tread Patterns and Grip

Tread patterns play a huge role in how well a skid steer handles different surfaces. Each pattern offers unique benefits for grip, stability, and surface protection. Operators often choose a tread based on the job site and ground conditions. Here’s a quick look at how different tread designs compare:

| Track Design Type | Key Features | Performance Characteristics | Ideal Applications |

|---|---|---|---|

| Multi-Bar Pattern | Parallel bars across track width; aggressive tread | Excellent traction in soft, loose terrain; self-cleaning; causes more surface disruption | Soft soils, muddy conditions, construction sites needing aggressive grip |

| C-Lug Pattern | Curved lugs with multidirectional traction | Reduced vibration; versatile across mixed surfaces; prevents material packing | Mixed-use environments, varied terrain, applications requiring smoother ride |

| Block Pattern | Offset individual tread blocks | Minimizes ground pressure and surface damage; smooth operation; less aggressive traction | Hard surfaces, landscaping, turf-friendly operations |

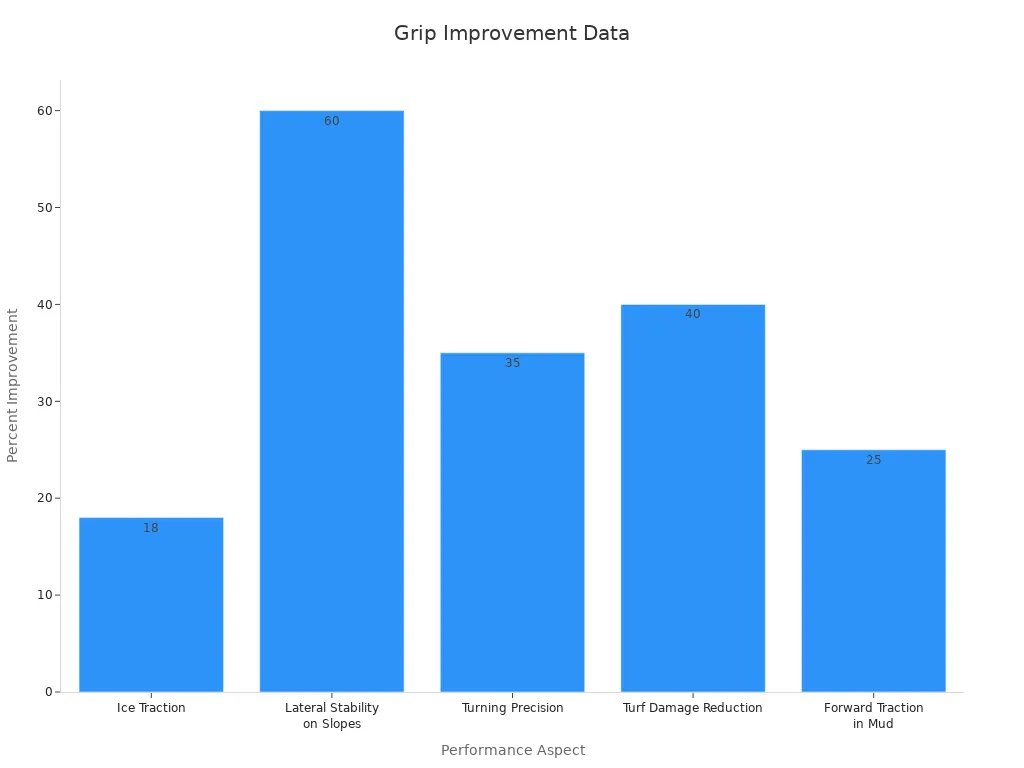

Research shows that lateral tread patterns, especially those with siping, can boost ice grip by up to 18%. These patterns also improve turning precision and reduce turf damage by up to 40%. Directional treads, on the other hand, give better forward traction in deep mud but may not offer as much lateral stability.

Tip: Choosing the right tread pattern can make a big difference in both safety and productivity, especially when working on challenging surfaces.

Track Width and Flotation

Track width affects how a skid steer moves over soft or uneven ground. Wider tracks spread the machine’s weight over a larger area, which lowers ground pressure. This helps prevent the machine from sinking into mud or snow and keeps the surface from getting damaged.

- Choosing the correct track width can increase productivity by up to 25%.

- Wider tracks provide better flotation, making it easier to work in muddy or snowy conditions.

- Lower ground pressure means less rutting and ground disturbance, which saves time on repairs.

- Operators find that wider tracks help avoid getting stuck, especially on soft terrain.

Rubber tracks for skid steer with the right width keep projects moving, even when the weather turns bad or the ground gets soft.

Terrain Compatibility and Versatility

Rubber tracks for skid steer are designed to handle a wide range of terrains. Specialized tread patterns and advanced materials help these tracks grip everything from mud and gravel to rocky ground. High-performance tracks can reduce ground pressure by up to 75% compared to wheeled machines, which is great for landscaping and farming.

- Multi-Bar treads work best in soft, loose conditions like mud.

- C-Lug patterns offer grip on mixed surfaces and help prevent material from packing into the tracks.

- Block patterns protect turf and minimize surface damage on hard ground.

Real-world examples show that farms using high-performance tracks can work longer during wet seasons and use less fuel. Construction crews have seen track life jump from 500 to over 1,200 hours, cutting replacement costs by about 30%. These results prove that the right rubber tracks for skid steer can handle almost any job site.

Construction and Material Quality

The quality of materials and construction methods makes a big difference in how long tracks last and how well they perform. Premium rubber tracks for skid steer use advanced rubber compounds that resist tearing, abrasion, and harsh weather. Steel core technology, like helical steel cords and anti-corrosion treatments, adds strength and flexibility.

| Material & Construction | Features | Benefits |

|---|---|---|

| Advanced rubber compounds (natural + synthetic blends) | Tear resistance, abrasion protection, temperature tolerance | Enhanced durability, flexibility, and weather resistance |

| Helical steel cord reinforcement | Spiral steel cables for multidirectional flexibility | Improved tensile strength, reduced stress concentration, longer track life |

| Anti-corrosion treatments | Galvanized/brass-coated cords, waterproof seals | Extended durability in wet/salty environments |

Testing shows that high-quality tracks can last over 1,200 hours, and with good maintenance, even up to 1,800 hours. Emergency repairs drop by 85%, and total track expenses can fall by 32%. These tracks also protect the undercarriage by absorbing impacts and reducing vibration, which helps expensive parts last longer.

Note: Our tracks for skid steer use specially formulated rubber and all-steel chain links. The steel parts are drop-forged and coated with a unique adhesive, creating a strong bond that keeps the track robust and reliable.

Benefits of Rubber Tracks for Skid Steer

Enhanced Traction and Stability

Rubber tracks for skid steer give machines a strong grip on tough surfaces. They help the skid steer move safely over slick mud, loose gravel, and even steep slopes. Many operators notice less slippage and better control, which means safer work and fewer accidents.

- Specialized tread patterns boost grip on different surfaces.

- Self-cleaning treads keep mud and debris from sticking, so the machine keeps moving.

- The wide footprint spreads out the weight, lowering ground pressure by up to 75%. This helps the machine float over soft ground instead of sinking.

- Advanced rubber and steel core designs keep the tracks flexible and strong, even in hot or cold weather.

These features make the machine more stable and help crews finish jobs faster.

Adaptability to Various Terrains

Rubber tracks for skid steer work well on many types of ground. They handle mud, sand, rocky paths, and even icy surfaces. Operators can switch between job sites without worrying about getting stuck or damaging the ground.

All-terrain tracks combine durability and flexibility, making them perfect for changing weather and surfaces. Some farms have used these tracks to work extra days during wet seasons. Construction companies have seen track life double, which means less time spent on repairs and more time working.

Durability and Cost-Effectiveness

Premium rubber tracks last longer than standard ones. They can run for 1,000 to 1,500 hours before needing replacement. This longer life means fewer track changes and less downtime.

- Fewer replacements save money on labor and parts.

- Better traction and stability help operators work faster and safer.

- Many brands offer warranties up to 2,000 hours, giving buyers peace of mind.

- Choosing the right track for the job boosts durability and keeps costs down.

A contractor finished grading work 30% faster with durable tracks, showing that the investment pays off over time.

Operator Comfort and Reduced Vibration

Operators feel the difference when using rubber tracks. The tracks absorb bumps and shocks from rough ground, making the ride smoother.

- Special designs reduce vibration, so operators feel less tired after long shifts.

- Suspension systems and rubber-on-rubber contact lower stress on the body.

- Controls are easier to reach, and the ride feels more comfortable.

Less vibration also protects the machine’s parts, helping everything last longer and work better.

Maintenance and Care for Rubber Tracks for Skid Steer

Regular Inspection and Cleaning

Keeping tracks clean and damage-free helps machines run longer. Operators should check for cuts, cracks, or metal showing every day. Removing dirt and rocks at the end of each shift stops debris from wearing down the rubber. A simple rinse with water works well, but a full cleaning with a pressure washer once a month removes stubborn mud. The table below shows how often to inspect and clean, plus the benefits:

| Inspection Frequency | Key Maintenance Tasks | Impact on Cleanliness and Longevity |

|---|---|---|

| Daily | Look for damage, rinse off debris | Stops early wear, keeps tracks clean |

| Weekly | Check tread and undercarriage parts | Finds problems before they get worse |

| Monthly | Deep clean, check tension | Extends track life, keeps machine safe |

Many crews have doubled track life and cut emergency repairs by following these steps.

Maintaining Proper Tension and Alignment

Proper tension keeps tracks from slipping off or wearing out too fast. Operators measure track sag at the middle point between the front idler and first roller. They use a grease gun to adjust tension, adding a little at a time and checking again. Tools like tension gauges and alignment indicators help get it right. If tracks feel loose or make strange sounds, it’s time to check. Keeping tension just right helps the machine work better and saves money on repairs.

Tip: Tracks that are too tight can break parts, while loose tracks can slip off. Daily checks make a big difference.

Timely Replacement and Longevity Tips

Tracks wear out over time, even with good care. Operators should look for signs like deep cracks, missing tread, or trouble staying on the rollers. If adjusting tension no longer works, it’s time for new tracks. To make tracks last longer, avoid sharp turns and spinning in place. Clean tracks after each job, and store the machine on a flat surface. Regular care means fewer breakdowns and more time working.

Reliable tracks for skid loader help machines work better and safer. Operators should look at tread pattern, width, and material quality before choosing. Regular care keeps traction strong. Need help picking the right track? Contact Changzhou Hutai Rubber Track Co., Ltd. for expert advice.

Author: Changzhou Hutai Rubber Track Co., Ltd.

Email: sales@gatortrack.com

Wechat: 15657852500

LinkedIn: https://cn.linkedin.com/company/changzhou-hutai-rubber-track-co.-ltd.

Changzhou Hutai uses special rubber compounds and all-steel chain links. Drop-forged steel parts and strong adhesive create a tough, long-lasting track for any job.

Post time: Jun-13-2025