Smooth rides and happy operators start with the right ASV Loader Tracks. Machines roll over rocky ground like mountain goats, thanks to advanced rubber and poly-cords. Take a look at the numbers:

| Metric | Traditional System | Advanced Rubber Tracks |

|---|---|---|

| Emergency Repair Calls | Baseline | 85% decrease |

A sturdy track means fewer breakdowns, longer work hours, and more smiles on the job site.

Key Takeaways

- Choosing the right ASV Loader Tracks boosts machine performance by providing superior traction, stability, and longer service life, which means fewer breakdowns and more work done.

- Regular maintenance like cleaning, tension checks, and smooth operation reduces wear and emergency repairs by up to 85%, saving time and money on costly fixes.

- ASV Loader Tracks improve operator safety and comfort by reducing vibration and providing a smooth ride, helping operators stay alert and focused throughout the workday.

How ASV Loader Tracks Enhance Performance and Safety

Superior Traction and Stability for Every Job Site

Mud, snow, sand, or rocky ground—every job site throws its own curveballs. ASV Loader Tracks handle them all like a pro. Their advanced tread patterns grip soft, loose terrain, pushing out mud and dirt with every turn. On icy mornings, staggered treads bite into slippery surfaces, keeping machines steady. Even hard-packed gravel feels like a smooth highway thanks to block tread designs that spread weight and reduce jolts.

Operators love the wide, low-pressure tracks. Machines float over soggy fields and sensitive lawns, leaving barely a mark. Landscapers, builders, and farmers all cheer for the way these tracks keep projects moving, rain or shine.

Here’s a quick look at how high-performance rubber tracks stack up against standard tracks:

| Performance Metric | High-Performance Rubber Tracks | Standard Tracks | Improvement |

|---|---|---|---|

| Expected Service Life | 1,000+ hours | 500-800 hours | Longer lifespan reduces replacements and downtime |

| Maintenance Requirements | Lower due to better materials | Higher | Reduced maintenance effort and cost |

| Downtime Costs | Reduced due to fewer failures | Higher | Less downtime improves productivity |

| Traction and Stability | Advanced tread design improves traction and stability | Lower quality traction | Safer operation at higher speeds and better cycle times |

The secret sauce? A completely suspended frame and a special rubber-on-rubber contact area. These features boost traction, flotation, and ground clearance, making every job site feel like home turf.

Reduced Wear and Extended Equipment Life

Nobody likes surprise breakdowns. ASV Tracks fight wear and tear with a vengeance. Their fiber-reinforced rubber and heavy-duty polyurethane wheels shrug off sharp rocks and debris. No steel cords means no rust, even after years in the mud. The open undercarriage design cleans itself, so dirt and stones don’t grind away at the parts.

- Internal drive sprockets with replaceable steel rollers keep metal-on-metal contact to a minimum.

- Track lugs on both sides almost eliminate derailment, saving time and money.

- Bogie wheels spread out the machine’s weight, lowering ground pressure and reducing stress on every component.

Operators see the difference. Emergency repairs drop by 85%. Replacement frequency falls from three times a year to just once. The tracks last up to 1,200 hours—sometimes even longer. That means more work, less downtime, and a happier bottom line.

Improved Operator Safety and Comfort

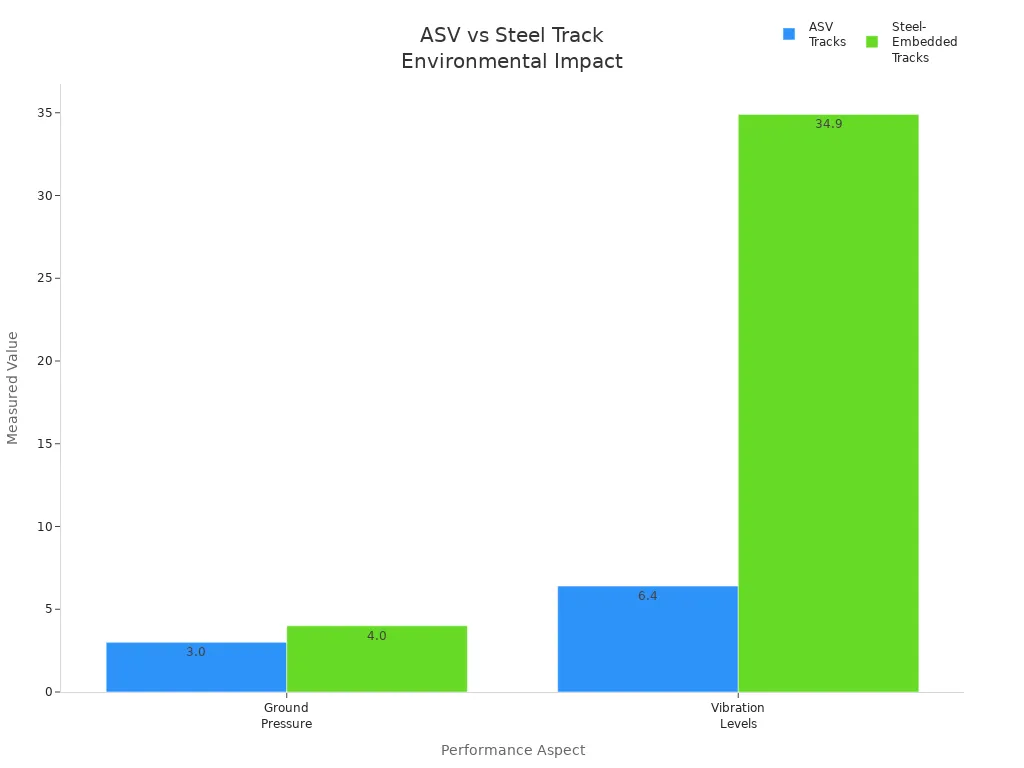

A smooth ride isn’t just about luxury—it’s about safety and focus. ASV Loader Tracks use a fully suspended frame and advanced suspension system to soak up bumps and shocks. Operators feel less vibration, even on rough ground. The cab stays quiet, dust-free, and comfortable, thanks to improved sealing and air circulation.

- Rubber tracks absorb shocks and reduce vibration by over 60%, keeping operators alert and less tired.

- Wide footprints and even weight distribution prevent machines from sinking or sliding, even on tricky slopes.

- Safety features like rollover and falling object protection keep operators safe from unexpected hazards.

Inside the cab, operators stretch out with more shoulder, knee, and foot room. Bluetooth radios and touchscreen displays turn long shifts into a breeze. Less fatigue means fewer mistakes and a safer job site for everyone.

Operators often say they finish the day feeling fresher and more focused. That’s the power of comfort and safety working together.

Maximizing Value with the Right ASV Loader Tracks

Lower Maintenance and Downtime

Nobody likes a machine that spends more time in the shop than on the job. ASV Loader Tracks keep downtime at bay with clever design and easy upkeep. Regular cleaning and tension checks help these tracks last longer and work harder. Operators who stick to a maintenance routine—like cleaning off mud and rocks, checking for wear, and adjusting tension—see fewer surprise repairs. In fact, emergency repairs drop by a whopping 85%. That means more time moving dirt and less time waiting for parts.

| Maintenance Issue | Description / Causes | Prevention Methods |

|---|---|---|

| Premature Wear | Heavy loads, sharp turns, rough terrain, bad tension | Inspect often, keep tension right, avoid wild maneuvers, use tough tracks |

| Uneven Wear | Bent frames, worn parts | Check undercarriage, use tracks with even ground contact |

| Track Damage | Sharp debris, too much pressure | Operate smoothly, use reinforced tracks |

| Debris Accumulation | Mud, gravel, plants | Clean after use, use easy-to-clean tracks |

| Maintenance Challenges | Skipped checks, bad cleaning, wrong tension | Stick to a schedule, use built-in tensioners, inspect and clean often |

Cost Savings on Repairs and Replacements

Money saved is money earned. ASV Loader Tracks use smart features like internal drive systems and open undercarriages to cut down on wear and repair bills. Operators enjoy longer service intervals and fewer costly part swaps. Some systems even offer warranties up to two years or 2,000 hours. Compared to other loaders, these tracks can lower operating costs by up to 40%. Fewer breakdowns and longer-lasting parts mean more cash stays in your pocket.

Practical Tips for Choosing and Maintaining ASV Loader Tracks

Choosing the right tracks feels like picking the perfect shoes for a race. Operators should match track width and tread to the job site—wide tracks for soft ground, tough treads for rocky spots. Regular cleaning, tension checks, and gentle driving keep tracks in top shape. In cold weather, avoid parking in slush and always clear out snow and ice. Training operators on smooth driving and daily checks helps tracks last even longer. A little care goes a long way!

Choosing the right ASV Loader Tracks turns tough jobs into smooth rides. Operators see fewer breakdowns and more finished work. Smart track choices and regular checks keep machines running strong.

A well-chosen track means less downtime, more savings, and a safer crew every day.

FAQ

How often should operators check loader tracks?

Operators check tracks daily. Quick inspections catch problems early. A clean track means a happy machine.

Tip: Morning checks save headaches later!

What terrain works best for these tracks?

These tracks tackle mud, snow, sand, and gravel. Operators glide over soggy fields and rocky paths.

- Mud

- Snow

- Sand

- Gravel

Can these tracks handle cold weather?

Yes! Special rubber stays flexible in freezing temperatures. Operators keep working, even when snow piles up.

:cloud_with_snow: No need to hibernate the loader!

Post time: Aug-19-2025