Dumper rubber tracks play a crucial role in construction by moving heavy materials across job sites with ease. They handle tough terrains and improve productivity, making them indispensable for infrastructure projects. The market for these vehicles reflects their importance, with projections showing growth from $23.23 billion in 2024 to $24.49 billion in 2025, driven by urbanization and efficiency demands.

Gator Track has emerged as a trusted name in rubber track manufacturing. By combining advanced materials, anti-vibration technology, and self-cleaning designs, the company delivers tracks that perform reliably under challenging conditions. Their commitment to quality ensures fewer replacements and better value for construction professionals worldwide.

Key Takeaways

- Dumper tracks help carry heavy materials on construction sites easily.

- Picking the right dumper track, like articulated for bumpy areas or mini for small spaces, makes work safer and better.

- Gator Track sells strong rubber tracks that last longer, saving money and needing fewer replacements.

Types of Dumper Tracks

Dumper tracks come in various types, each designed to meet specific construction needs. Understanding their differences can help construction professionals choose the right equipment for their projects. Let’s explore the four main types of dumper tracks.

Rigid Dumper Tracks

Rigid dumper tracks are built for heavy-duty tasks. They excel at transporting large quantities of materials over long distances, especially on flat terrains. These machines are known for their durability and speed, making them ideal for open roads, mines, and quarries.

| Specification | Value |

|---|---|

| Payload capacity | 95,000 kg |

| Body volume, SAE 2:1 heap | 60.4 m³ |

| Net weight | 69,752 kg |

| Gross weight | 164,752 kg |

| Engine | Cummins QST30 |

| Gross power | 783 kW |

| Max SAE J1349 gross torque | 4,631 Nm |

Tip: Features like Volvo Dynamic Shift Control and Eco Shift Mode enhance drivetrain performance and fuel efficiency. These tracks also include auto-idle engine shutdown and On-Board Weighing options, which improve safety and reduce operational costs.

Articulated Dumper Tracks

Articulated dumper tracks are versatile and designed for rough terrains. They feature a hinge that allows the front and rear sections to move independently, ensuring stability even on uneven ground. These tracks are commonly used in mining, agriculture, and heavy construction.

- Key features include:

- An articulation hinge that distributes weight evenly to the front axle, improving stability during sharp turns.

- A free-swinging rear tandem bogie that ensures all six wheels maintain contact with the ground, enhancing traction.

- EP320 transmission with multiple gears for smoother shifts and better operator comfort.

These machines can haul up to 28 tonnes and offer a 5% improvement in fuel efficiency. Extended maintenance intervals (up to 4,000 hours) reduce downtime, making them a cost-effective choice for demanding projects.

Tracked Dumper Tracks

Tracked dumper tracks are perfect for challenging environments. Their rubber tracks provide excellent traction on muddy or slippery surfaces, allowing them to navigate steep inclines with ease. These tracks are often used during the early stages of construction when the ground is uneven or unstable.

| Type of Dumper Truck | Characteristics | Applications |

|---|---|---|

| Tracked Dumper Trucks | Great traction on muddy ground, can travel on steep inclines | Early stages of construction |

Their ability to handle difficult terrains makes them indispensable for projects in remote or rugged locations. Gator Track’s high-quality rubber tracks ensure durability and performance, even under extreme conditions.

Mini Dumper Tracks

Mini dumper tracks are compact and highly maneuverable, making them ideal for restricted construction sites. Despite their small size, they pack a punch in terms of performance. These tracks are commonly used for landscaping, small-scale construction, and urban projects.

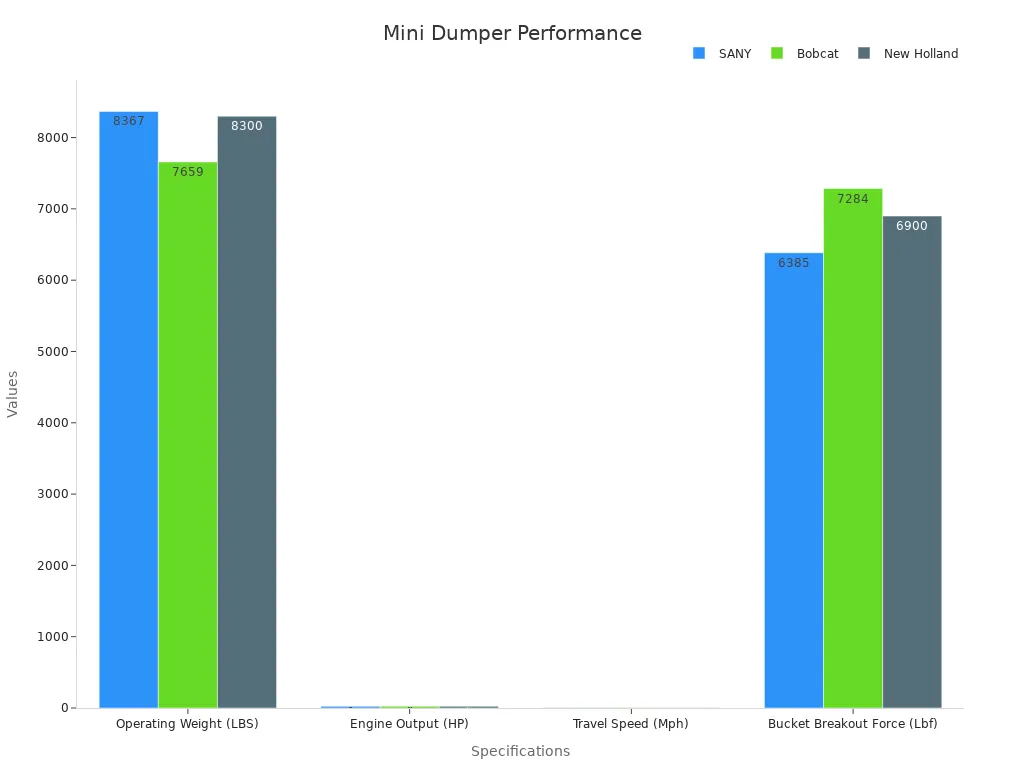

| Specifications | SANY | Bobcat | New Holland |

|---|---|---|---|

| Operating Weight (LBS) | 8,367 | 7,659 | 8,300 |

| Engine Output (HP) | 23.3 | 24.8 | 24.4 |

| Tail Swing | Zero | Zero | 2’10″ |

| Travel Speed (Mph) | 2.7 | 2.9 | 2.6 |

| Max Ground Level Reach | 17’11″ | 17′ | 17’1″ / 18′ |

| Dig Depth | 10’2″ | 10’1″ | 10’3″ / 11’3″ |

| Bucket Breakout Force (Lbf) | 6,385 | 7,284 | 6,900 |

Note: Mini dumper tracks like SANY and Bobcat offer impressive digging force and zero tail swing, making them perfect for confined spaces. Their compact design ensures they can operate efficiently in areas where larger equipment cannot.

Each type of dumper track serves a unique purpose, and selecting the right one can significantly impact the efficiency and safety of a construction project.

Uses of Dumper Tracks in Construction

Dumper tracks are indispensable on construction sites, offering versatility and reliability for various tasks. Their ability to transport heavy materials, navigate challenging terrains, and boost efficiency makes them a cornerstone of modern construction practices.

Transporting Heavy Materials

One of the primary uses of dumper rubber track is moving heavy materials across construction sites. These vehicles are designed to handle substantial loads, ensuring that materials like gravel, sand, and debris are transported efficiently. Rigid dumper trucks, for instance, excel at carrying large quantities over long distances, making them ideal for large-scale projects.

| Type of Dumper Truck | Application in Construction |

|---|---|

| Rigid Dumper Trucks | Used for larger loads, durable and fast, ideal for transporting materials between sites. |

| Articulated Dumper Trucks | Suitable for difficult terrain, requires skilled operatives, used once materials arrive on site. |

| Tracked Dumper Trucks | Best for rough terrain and adverse weather, flattens ground for safety, favored in early construction stages. |

| Mini Dumper Trucks | Smaller versions for home and garden projects, easy to operate with a category B license. |

Statistical data highlights the efficiency of dumper tracks in material transportation. For example, fully loaded vehicles account for 42% of trips, while empty vehicles leaving sites make up 59%. This demonstrates their critical role in maintaining a steady workflow on construction sites.

| Metric | Value |

|---|---|

| Ratio of fully loaded vehicles | 42% |

| Ratio of empty vehicles leaving | 59% |

| Ratio of full vehicles leaving | 29% |

| Ratio of empty to full returns | 2:1 |

Navigating Rough and Uneven Terrains

Construction sites often feature rough and uneven terrains that can challenge traditional vehicles. Dumper tracks, especially tracked models, are built to handle these conditions with ease. Their rubber tracks provide excellent traction and stability, ensuring safe navigation even on soft ground, mud, or gravel.

- Dumper tracks conform to various terrains, offering a firm grip on slippery or uneven surfaces.

- Innovative tread designs and durable materials enhance their performance in challenging environments.

- Tracked dumper trucks are particularly effective during the early stages of construction when the ground is unstable.

This adaptability makes dumper tracks a reliable choice for projects in remote or rugged locations. By flattening the ground as they move, they also create safer pathways for other equipment.

Enhancing Efficiency on Construction Sites

Efficiency is a top priority in construction, and rubber track dumper plays a significant role in achieving it. Their ability to transport materials quickly and navigate difficult terrains reduces downtime and keeps projects on schedule. Mini dumper tracks, for example, are perfect for confined spaces, allowing workers to complete tasks that larger vehicles cannot handle.

Tip: Choosing the right type of dumper track for specific tasks can significantly improve productivity. For instance, articulated dumper trucks are ideal for maneuvering through tight spaces, while rigid models are better suited for long-distance hauling.

Gator Track’s high-quality rubber tracks further enhance efficiency by minimizing wear and tear. Their durability ensures fewer replacements, saving time and costs for construction professionals. This commitment to quality makes Gator Track a trusted partner in the industry.

Understanding the different types and uses of dumper tracks is key to optimizing construction projects. Choosing the right track ensures safety, boosts efficiency, and keeps operations smooth. Gator Track stands out with its dedication to crafting durable, high-performance rubber tracks.

Post time: May-06-2025