Top China Manufacturer of Robot Rubber Tracks and Robot Platforms

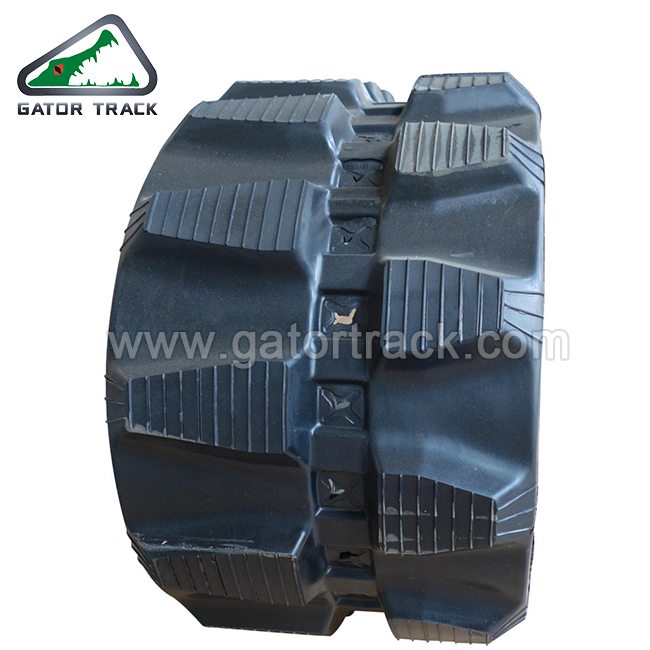

As a leading manufacturer of China Robot Rubber Track and Robot Platform, I understand the unique needs of B2B purchasers like you. Our products are engineered to provide unmatched durability and performance, making them ideal for various robotic applications. With our rubber tracks, you can expect enhanced traction and stability, allowing your robots to navigate diverse terrains effortlessly. We pride ourselves on using high-quality materials and innovative design to ensure longevity and reliability. Our robot platforms offer flexibility, easily accommodating various payloads and configurations to suit your project requirements. Collaborating with us means you're not just getting exceptional products; you're also gaining a partner committed to your success. Let’s optimize your robotic solutions together. Choose our robots tracks and platforms to elevate your capabilities in the competitive market. Reach out today and we can discuss how to best meet your specific needs!

China Robot Rubber Track and Robot Platform Stands Out in 2025

In 2025, the robotics industry is witnessing rapid advancements, with a significant focus on high-performance components that drive innovation and efficiency. Among these, rubber tracks and robot platforms have emerged as crucial elements in various applications, from automation and logistics to agriculture and construction. The combination of durability, versatility, and design excellence has made these products indispensable for global manufacturers and operators looking to enhance their operational capabilities. The standout features of rubber tracks include superior traction, reduced ground disturbance, and exceptional wear resistance, making them ideal for indoor and outdoor applications. Additionally, the advanced engineering behind these tracks ensures compatibility with a wide range of robotic systems, thus providing procurement specialists with flexible solutions tailored to their specific needs. Meanwhile, robot platforms are designed to offer robust support for various payloads and configurations, enabling seamless integration with diverse robotic technologies. As a result, businesses are better equipped to tackle challenges in their respective industries while maintaining operational efficiency. As the demand for automation solutions grows worldwide, sourcing reliable and innovative rubber tracks and robot platforms becomes increasingly vital. Companies investing in these technologies will benefit from improved productivity and reduced operational costs, positioning themselves advantageously in an ever-competitive market. With a keen understanding of the future trends driving robotics, stakeholders can make informed decisions to select the right products that align with their business objectives, ensuring sustained growth and success in the coming years.

China Robot Rubber Track and Robot Platform Stands Out in 2025

| Category | Specifications | Features | Applications | Market Trends |

|---|---|---|---|---|

| Rubber Tracks | Width: 300 mm, Material: Natural Rubber | High Durability, Low Friction | Agriculture, Military | Increasing Demand for Off-Road Vehicles |

| Robot Platforms | Payload: 100 kg, Speed: 2 m/s | Modular Design, Quick Assembly | Logistics, Construction | Growth in Automation Technology |

| Navigation Systems | GPS + Lidar, Accuracy: 2 cm | Real-Time Mapping, Obstacle Avoidance | Delivery, Surveying | Rise in Remote Operations |

| Battery Systems | Type: Lithium-Ion, Capacity: 50 Ah | Fast Charging, Long Cycle Life | Drones, Robots | Sustainable Energy Solutions |

Related Products