Mini Excavator Rubber Tracks to Poland | China Manufacturer Solutions

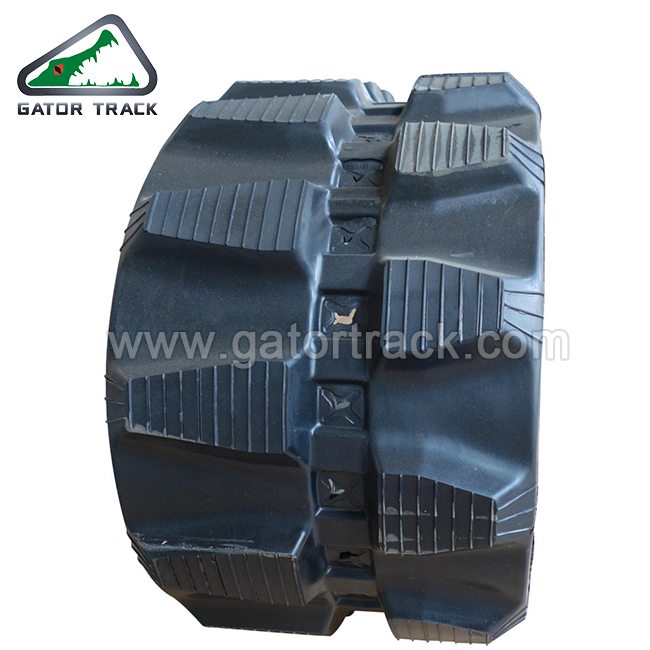

When it comes to sourcing Mini Excavator Rubber Tracks to Poland, partnering with a reliable manufacturer from China is key. Having spent years in the industry, I understand the need for durable and high-performance rubber tracks that can handle various terrains and weather conditions. Our tracks are designed with precision engineering, ensuring a perfect fit for your excavators and maximum efficiency in your operations. I pride myself on offering quality products that not only meet international standards but also provide excellent value for your investment. By choosing us, you're not just buying tracks; you're investing in a solution that enhances your machinery's performance. Together, we can help you tackle any project with confidence, knowing that you have the best of Chinese manufacturing behind you. Let’s discuss how our Mini Excavator Rubber Tracks can meet your needs and take your business to the next level in Poland.

Mini Excavator Rubber Tracks to Poland Stands Out Industry Leaders

When it comes to mini excavators, the quality of rubber tracks plays a critical role in performance, durability, and overall efficiency. Companies seeking reliable excavator solutions often find themselves overwhelmed with choices. However, those sourcing from the industry leaders recognize that superior rubber tracks can significantly enhance operational capabilities on job sites. This is especially true for consumers in Poland, where varying terrains and demanding work conditions call for robust and resilient machinery components. The standout features of high-quality rubber tracks include exceptional traction, reduced vibration, and remarkable resistance to wear and tear. Moreover, these tracks are designed to be compatible with various mini excavator models, making them versatile options for contractors and rental services. As global demand for mini excavators increases, prioritizing the procurement of top-tier rubber tracks is essential for businesses looking to maximize equipment performance and minimize downtime. Investing in leading-edge rubber tracks translates to long-term savings and enhanced productivity. Businesses can capitalize on the advantages of employing advanced rubber technology, ensuring that their machinery remains efficient and reliable under challenging conditions. For procurement professionals and decision-makers, selecting the right rubber tracks not only supports operational effectiveness but also reflects a commitment to quality and excellence in construction practices.

Mini Excavator Rubber Tracks to Poland Stands Out Industry Leaders

| Dimension | Material | Compatibility | Weight Capacity | Performance Rating |

|---|---|---|---|---|

| 300mm | Natural Rubber | Excavator Model A | 2,000 kg | High |

| 450mm | Synthetic Rubber | Excavator Model B | 3,000 kg | Excellent |

| 600mm | Reinforced Rubber | Excavator Model C | 4,000 kg | Superior |

| 800mm | Heavy-Duty Rubber | Excavator Model D | 5,000 kg | Outstanding |

Related Products