Top China Manufacturer of Rubber Track Patterns for All Applications

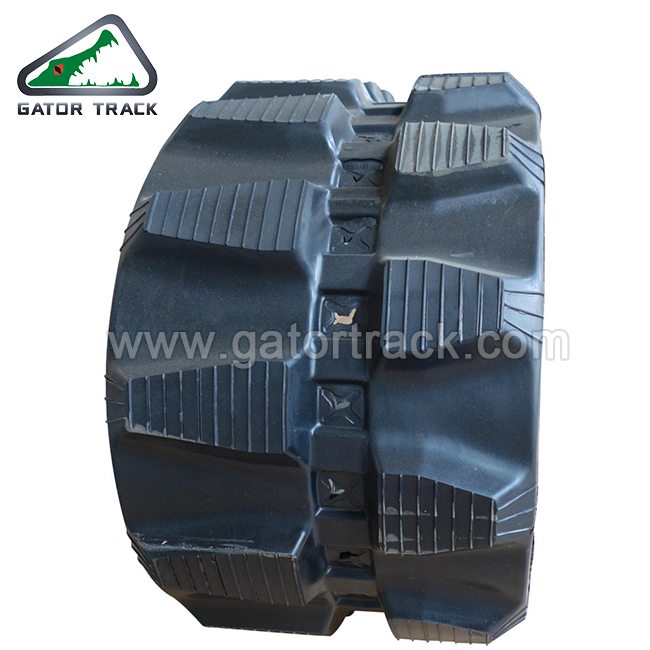

When I think about rubber track patterns, I picture the critical role they play in ensuring optimal performance across various terrains. Sourced from leading manufacturers in China, our rubber tracks are designed to deliver durability and reliability that you can trust. Whether you're in construction, agriculture, or any other industry requiring heavy machinery, these tracks offer superior traction and stability, reducing wear and tear on your equipment. Every pattern is carefully engineered to enhance efficiency and safety, making them perfect for demanding environments. As a buyer, you'll appreciate the attention to detail and quality that goes into each product. Plus, our competitive pricing and commitment to customer satisfaction mean you get the best value without compromising on performance. If you’re ready to elevate your machinery’s capabilities, let’s discuss how our rubber track patterns can meet your specific needs.

Rubber Track Patterns Products Leads the Global Market

In the rapidly evolving world of construction and agricultural machinery, the significance of high-quality rubber tracks cannot be overstated. As industries continue to embrace advanced technologies and seek operational efficiency, the patterns and materials used in rubber track manufacturing have become crucial for performance, reliability, and safety. Among the various options available, a variety of innovative rubber track patterns have emerged, each designed to meet specific operational needs while providing maximum traction and durability. The growing global market for rubber track patterns underscores a shift towards equipment that not only meets rigorous performance standards but also adapts to diverse terrains and conditions. Whether operating on muddy fields, rocky surfaces, or urban environments, the right rubber track pattern enables heavy machinery to perform optimally, reducing downtime and maintenance costs. For buyers worldwide, this translates into a smart investment that enhances productivity and extends the lifespan of their machinery. As businesses look to secure a competitive edge, understanding the latest trends in rubber track technology becomes essential. From improved manufacturing techniques that ensure consistent quality to advanced tread designs that enhance grip, staying informed can empower global purchasers to make decisions that align with their operational goals. As the demand for efficient and reliable machinery rises, connecting with reputable suppliers of rubber track patterns is more important than ever. Leveraging quality tracks tailored to specific applications can ultimately drive success and growth in any operation.

Rubber Track Patterns Products Leads the Global Market

| Pattern Type | Application | Material Grade | Market Share (%) | Growth Rate (2023) |

|---|---|---|---|---|

| Tread Pattern A | Construction | Premium | 25% | 8% |

| Tread Pattern B | Agricultural | Standard | 15% | 5% |

| Tread Pattern C | Mining | Heavy Duty | 20% | 6% |

| Tread Pattern D | Forestry | Specialized | 30% | 10% |

| Tread Pattern E | Landscaping | Eco-Friendly | 10% | 4% |

Related Products