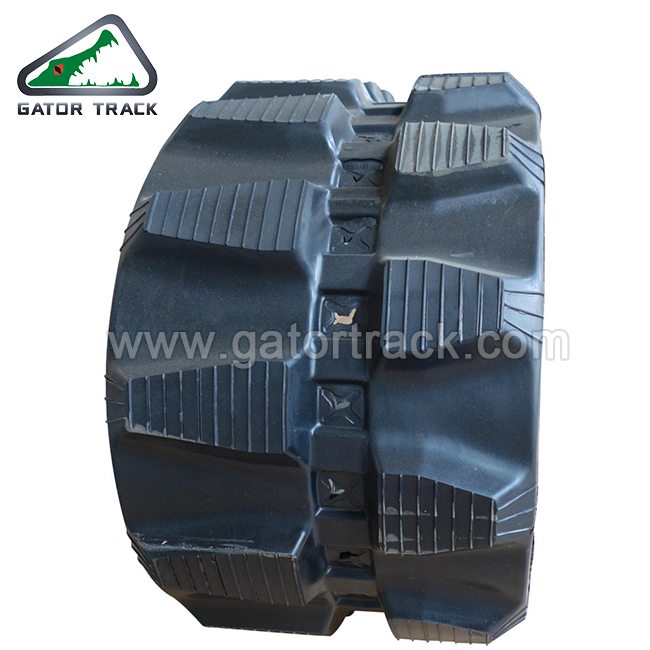

Wholesale Mini Excavator Rubber Tracks from Leading China Manufacturer

When it comes to sourcing high-quality wholesale mini excavator rubber tracks, I know how crucial it is to partner with a reliable manufacturer, especially in China. Our rubber tracks are crafted with durability in mind, ensuring that your mini excavators can handle the toughest terrains while providing optimal performance. I’ve seen firsthand how our products stand up against competitors, offering superior traction and longer wear life, which translates into cost savings for your operations. With a variety of sizes and specifications available, you’ll find the perfect fit for your machinery. Plus, working directly with a reputable manufacturer means you can expect consistent quality and timely delivery. I’ve built relationships with many satisfied B2B clients who rely on our tracks to maintain their equipment efficiency. Let's discuss how we can meet your needs and help your business thrive in the competitive marketplace!

Wholesale Mini Excavator Rubber Tracks Manufacturers You Can Rely On Factory-Direct Excellence

When it comes to sourcing quality rubber tracks for mini excavators, reliability and excellence are paramount. As a global buyer in the construction and machinery industry, partnering with manufacturers that specialize in wholesale rubber tracks can provide significant advantages. The optimal choice is to work directly with factories that emphasize quality control, innovative production techniques, and adherence to industry standards. By choosing factory-direct suppliers, you ensure better pricing and consistent product quality, which are essential for maintaining your competitive edge. Understanding the variety of rubber tracks available is crucial. Different models cater to diverse machinery needs, and working with manufacturers that offer a wide range of options allows buyers to tailor their purchases. The best suppliers can provide tracks that are engineered for enhanced durability and performance, which translates to reduced downtime and improved efficiency on job sites. Furthermore, established manufacturers often have the capability to customize products to meet specific requirements, ensuring your machinery operates at its best. In today’s global market, maintaining strong supply chain relationships is vital for seamless operations. Choosing reputable wholesale manufacturers not only mitigates risk but also fosters confidence in procurement processes. Factory-direct excellence can lead to improved product availability and consistent supply, essential factors in meeting project deadlines and client expectations. By prioritizing partnerships with trustworthy manufacturers, businesses can secure the high-quality rubber tracks essential for their mini excavators, ultimately driving project success and customer satisfaction.

Wholesale Mini Excavator Rubber Tracks Manufacturers You Can Rely On Factory-Direct Excellence

| Manufacturer Location | Experience (Years) | Production Capacity (Units/Year) | Material Used | Certifications |

|---|---|---|---|---|

| USA | 15 | 5000 | Natural Rubber | ISO 9001 |

| Germany | 20 | 7000 | Synthetic Rubber | CE, TUV |

| China | 10 | 8000 | Nitrile Rubber | ISO 14001 |

| Japan | 25 | 6000 | EPDM Rubber | JIS, RoHS |

| Italy | 12 | 4500 | Butyl Rubber | OHSAS 18001 |

Related Products