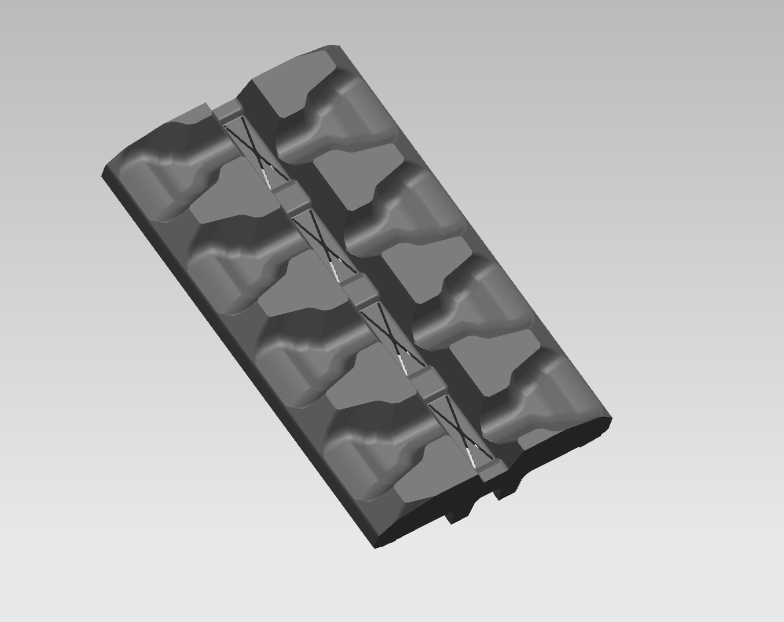

HXP450HD Track pad excavator

Excavator track pads HXP450HD

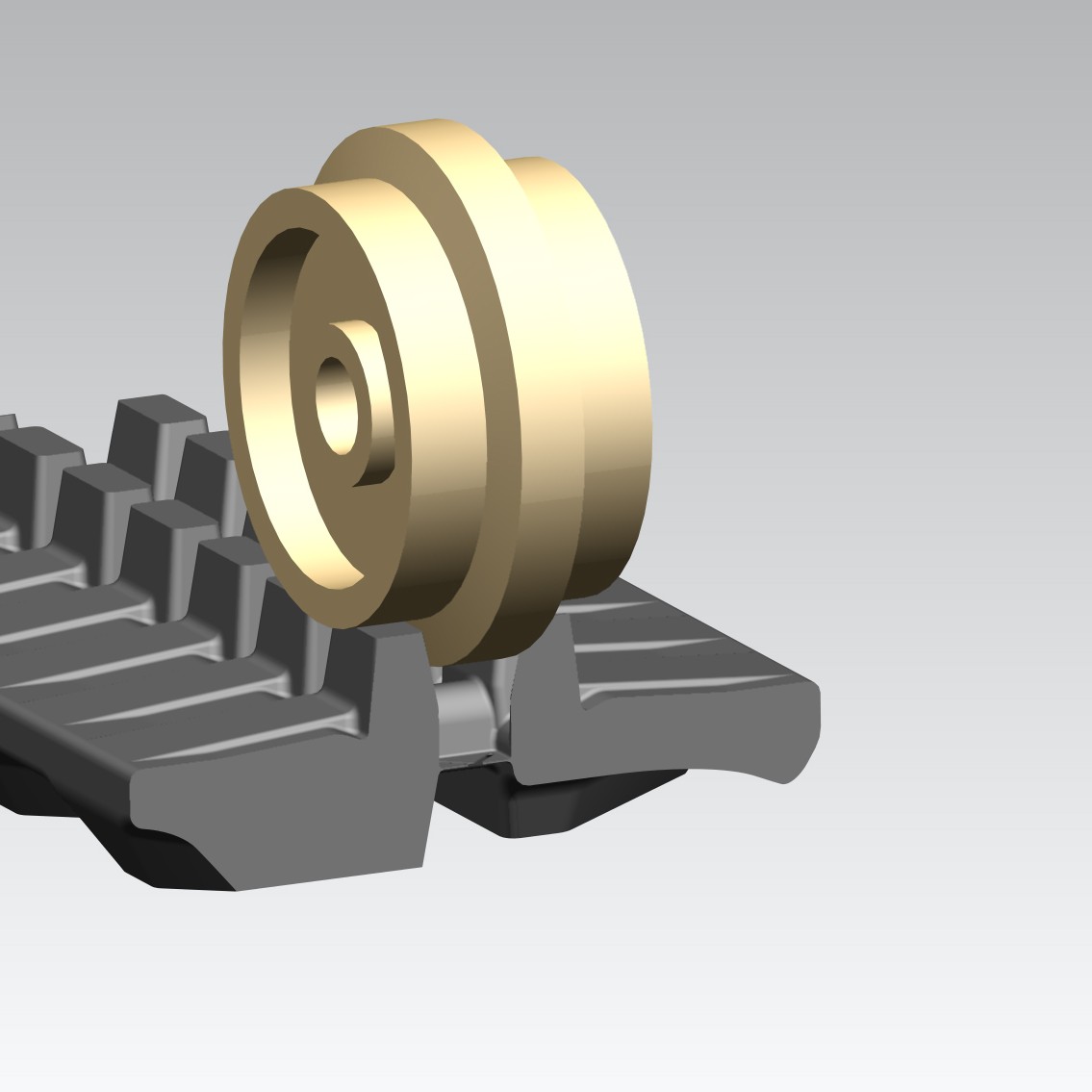

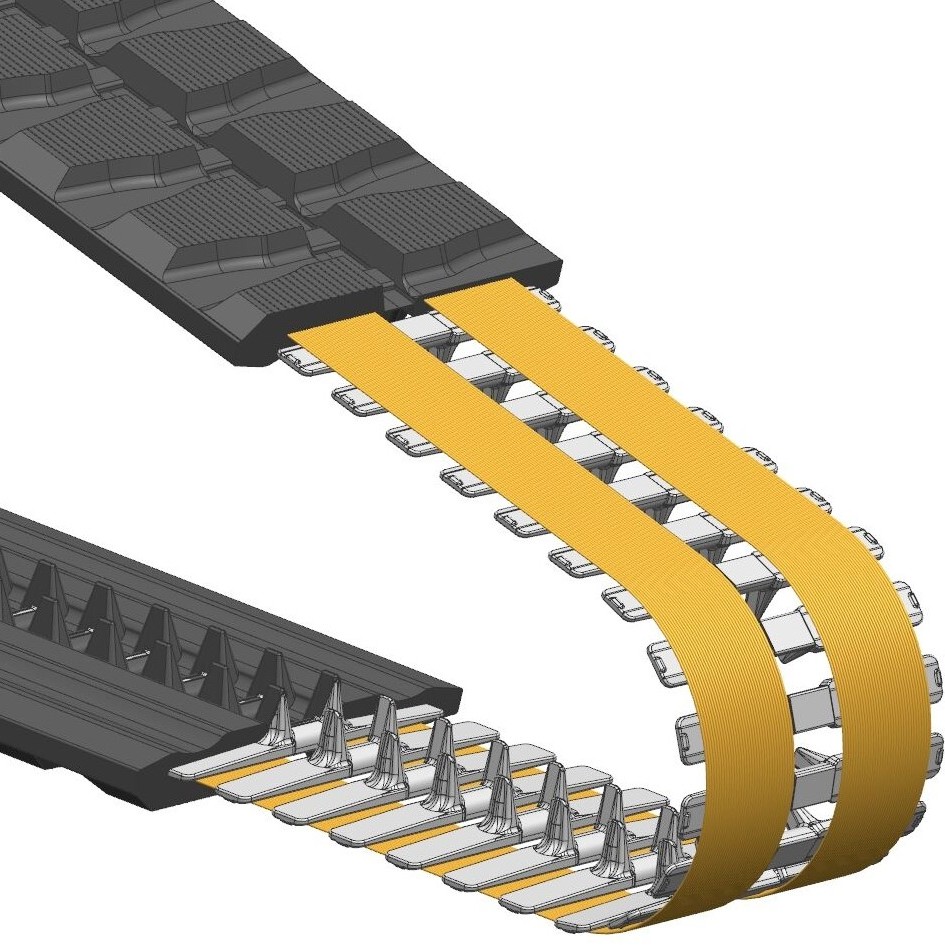

Certain industries require specialized excavator rubber pads designed for unique operational demands. In the forestry sector, rubber pads excavator models feature deep, self-cleaning treads to prevent mud and wood debris accumulation. For demolition work, reinforced excavator track pads with embedded steel plates provide extra protection against sharp debris. Pipeline installation crews use wide excavator pads to distribute weight across unstable terrain. Municipalities often choose white or light-colored digger track pads for improved visibility in nighttime operations. The mining industry utilizes extra-thick rubber compounds in their excavator pads to withstand abrasive ore materials. This versatility allows contractors to select precisely engineered excavator track pads matching their specific operational requirements and environmental conditions.

The excavator rubber pads industry continues to evolve with cutting-edge material science advancements. Emerging technologies include smart rubber pads excavator embedded with sensors to monitor wear patterns and ground pressure in real-time. Self-healing rubber compounds are being developed to automatically repair minor cuts or abrasions in excavator track pads. Some manufacturers are experimenting with graphene-enhanced rubber to create ultra-durable digger track pads with twice the lifespan of conventional models. Hybrid designs combining rubber’s flexibility with strategic metal inserts are gaining popularity for extreme-duty applications. As automation grows in construction, excavator pads are being optimized for use with autonomous digging machines. These innovations ensure that rubber-based excavator track pads will remain at the forefront of undercarriage technology, offering ever-improving performance and efficiency.

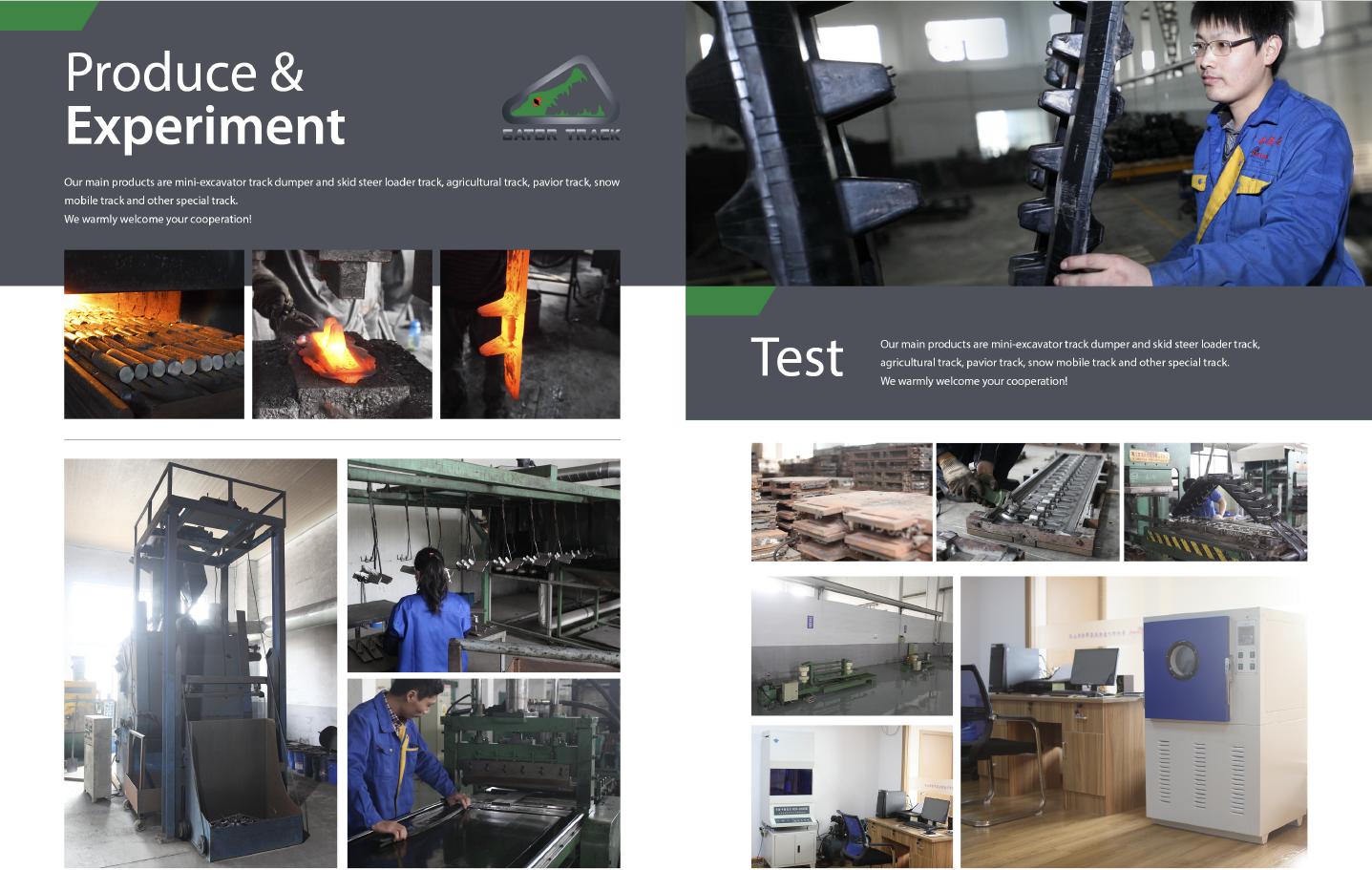

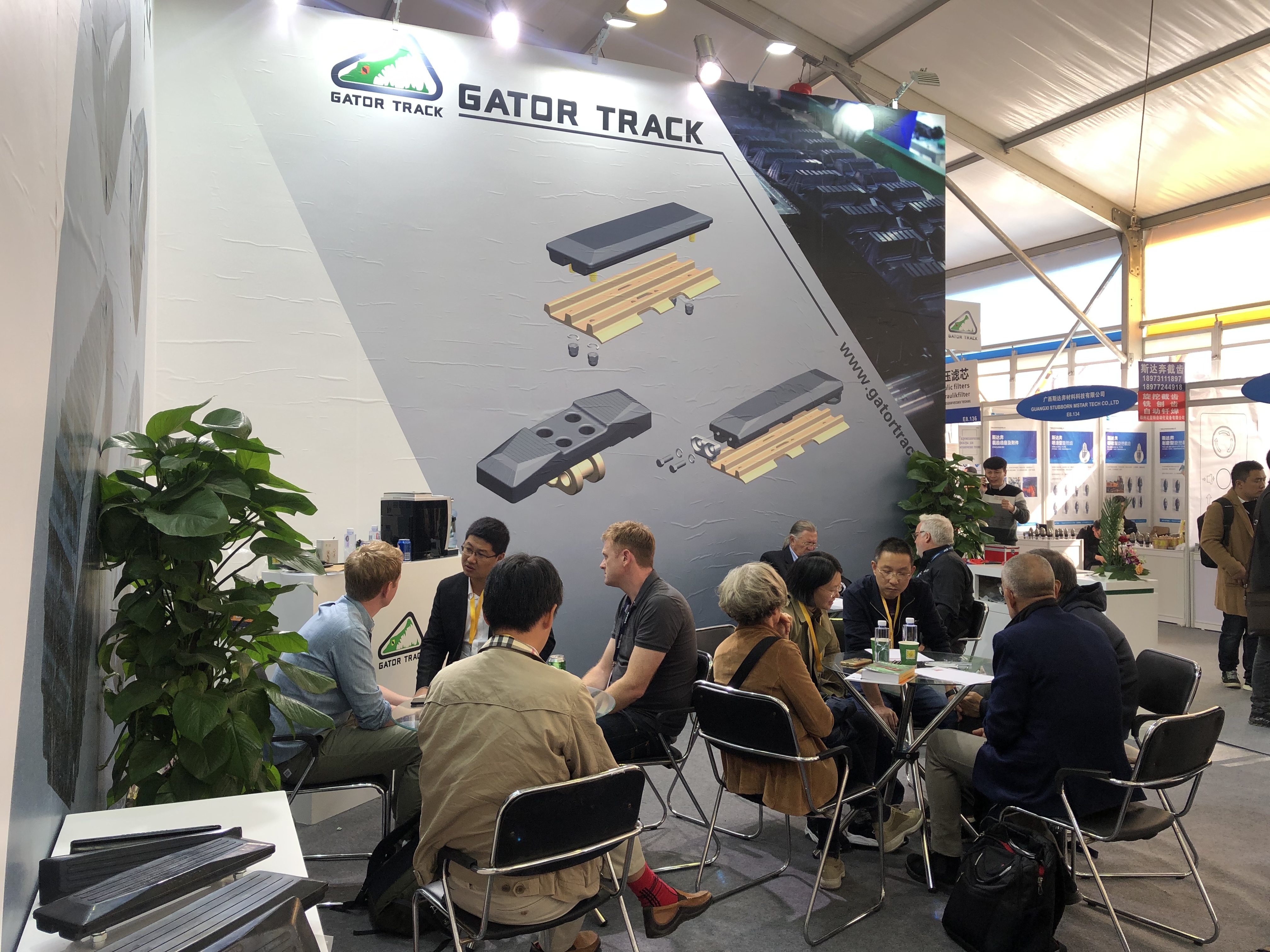

Founded in 2015, Gator Track Co., Ltd, is specialized in manufacturing rubber tracks and rubber pads. Production plant locates at No. 119 Houhuang, Wujin District, Changzhou, Jiangsu Province. We are happy to meet customers and friends from all parts of the world, it is always joyful to meet in person!

We currently have 10 vulcanization workers, 2 quality management personnel, 5 sales personnel, 3 management personnel, 3 technical personnel, and 5 warehouse management and container loading personnel.

Currently, our production capacity is 12-15 20 feet containers of rubber tracks per month. Annual turnover is US$7 million

1. What is your minimum order quantity?

We do not have a certain quantity requirement to start, any quantity is welcome!

2. How long is the delivery time?

30-45 days after order confirmation for 1X20 FCL.

3. Which port is closest to you?

We usually ship from Shanghai.

4. What advantages do you have?

A1. Reliable quality,Resonable prices and quick aftersales service.

A2. Punctual delivery time. Normally 3 -4 weeks for 1X20 container

A3. Smooth shipping. We have expert shipping department and forwarder, so we can promise faster

delivery and make the goods well protected.

A4. Customers all over the world. Rich experience in foreign trade, we have customers all over the world.

A5. Active in reply.Our team will respond your request within 8-hour working time. For more questions

and details, pls contact us by email or WhatsApp.