Skid Steer Rubber Tracks help machines move faster and work longer, especially on soft or muddy ground. Operators notice less downtime and more finished tasks.

| Performance Metric | Improvement with Rubber Tracks Compared to Tires |

|---|---|

| Productivity boost | Up to 25% increase in work speed |

| Usage frequency | 2 to 3 times more usage of compact loaders |

| Downtime in bad weather | Reduced downtime, increasing operational hours |

| Soil compaction reduction | 15% less soil compaction |

| Landscaping work speed in urban areas | 20% faster completion |

Key Takeaways

- Skid steer rubber tracks boost machine performance by improving traction, stability, and speed on soft or uneven ground, helping operators finish jobs faster and safer.

- Choosing the right track width, tread pattern, and rubber compound for your job site conditions maximizes equipment efficiency and protects delicate surfaces from damage.

- Regular maintenance, including daily track tension checks and cleaning, extends track life, reduces repair costs, and keeps machines running smoothly.

Skid Steer Rubber Tracks vs. Tires

Performance Comparison

Skid steer loaders can use either tires or rubber tracks. Each option has unique strengths. Tires work well on flat, hard surfaces like concrete or asphalt. They allow the machine to move quickly and turn easily. However, tires have a smaller contact area with the ground. This can cause the machine to sink or get stuck on soft, muddy, or snowy surfaces. Tires may also damage delicate surfaces, such as turf or indoor floors.

Skid Loader Tracks spread the machine’s weight over a larger area. This reduces ground pressure and helps the loader “float” over soft or uneven ground. The wide tracks protect surfaces from damage and provide a smoother ride with less vibration. Operators notice less noise and more comfort during long work hours. The table below highlights key differences:

| Feature | Tires | Rubber Tracks |

|---|---|---|

| Speed on hard ground | High | Moderate |

| Traction on soft ground | Low | High |

| Surface protection | Low | High |

| Stability on slopes | Moderate | High |

| Ride comfort | Moderate | High |

Advantages in Traction and Stability

Rubber tracks give skid steers better traction on wet, muddy, or slippery ground. The wide footprint and special tread patterns grip the surface and prevent slippage. This makes it easier to work on hills, loose soil, or snow. The tracks also lower the center of gravity, which helps the machine stay steady on slopes and reduces the risk of tipping.

Operators find that tracked skid steers can push into tough soils and move heavy loads with less risk of getting stuck. The tracks help the machine stay balanced and safe, even when lifting or digging. Self-cleaning treads keep mud and debris from building up, so the machine keeps its grip. These features make Skid Steer Rubber Tracks a smart choice for challenging job sites.

How Skid Steer Rubber Tracks Enhance Performance

Traction on Soft and Uneven Ground

Skid steer loaders often face soft, muddy, or uneven surfaces. Tracks for skid steer help these machines move where tires might fail. Several features make this possible:

- Advanced rubber compounds blend natural and synthetic materials. These compounds give the tracks elasticity and resist tearing or abrasion.

- Steel core technology uses helical steel cords. These cords add strength and flexibility, so the tracks do not stretch or break under pressure.

- Specialized tread patterns improve grip and help the tracks clean themselves. Mud and debris do not build up, so the machine keeps moving.

- A larger contact area spreads the machine’s weight. This reduces ground pressure and helps the loader float over soft ground.

- Corrosion-resistant coatings protect the steel inside the tracks. These coatings keep the tracks strong, even in wet or harsh conditions.

Wider tracks also help by spreading the weight over more ground. This prevents the machine from sinking or getting stuck in mud or sand. The increased number of gripping points gives better traction and pushing power. Operators can work on loose or slippery surfaces with less risk of slipping or stumbling.

Stability and Operator Comfort

Stability matters when a skid steer works on slopes or carries heavy loads. Tracks lower the machine’s center of gravity. This makes the loader less likely to tip over. The design of the tracks also keeps the machine steady on uneven ground.

Operator comfort improves with high-quality tracks. The arrangement of lugs in some tread patterns reduces vibration. Multi-bar tracks are known for giving a smooth ride. Advanced rubber compounds act as shock absorbers. They dampen vibrations and keep the cab quiet. Steel cords and Kevlar reinforcements prevent the tracks from deforming. This keeps the ride smooth, even after long hours of work.

Tip: Well-maintained tracks reduce vibration and noise. This helps operators stay focused and less tired during long shifts.

Surface Protection and Reduced Ground Damage

Tracks protect the ground better than tires. They spread the weight of the machine, which lowers ground pressure. This means less soil compaction and less damage to turf or landscaping. Tracks with smooth tread patterns leave a lighter footprint. Landscapers and contractors use these tracks on golf courses, parks, and gardens to avoid harming delicate surfaces.

- Rubber tracks can be used on pavement, concrete, and lawns without causing marks or damage.

- Some tracks come with non-marking rubber pads. These pads prevent black marks on sidewalks and driveways.

- Tracks glide smoothly over soft or sensitive terrain. They do not sink or tear up the ground.

- Special tread designs balance traction and turf protection. This makes them ideal for jobs where surface care is important.

Skid Steer Rubber Tracks allow machines to work in more places with less risk of damaging the environment. This makes them a smart choice for anyone who needs to protect the ground while getting the job done.

Types of Skid Steer Rubber Tracks

Common Tread Patterns and Their Uses

Skid steer loaders use different tread patterns to match job site needs. Each pattern offers unique features for specific tasks. The table below shows some of the most common tread patterns and their recommended uses:

| Tread Pattern | Features | Recommended Applications |

|---|---|---|

| C-Lug | Staggered C-shaped notches, smooth ride, high traction | Highway, off-road, versatile use |

| Staggered | Durable, heat-resistant, handles rough surfaces | Rocky, gravel terrains, highways |

| Straight-Bar | Aggressive, best for mud and wet ground | Muddy, wet environments |

| Multi-Bar | Smooth ride, good on loose and hard surfaces | Mixed job sites, snow removal |

| Block | Large contact area, even weight, moderate self-cleaning | Asphalt, concrete, mud, general use |

| V | Deep angled lugs, directional, minimal ground disturbance | Agriculture, light tasks |

| Zig Zag | High grip, self-cleaning, directional | Mud, snow, loose ground |

| Turf | Smooth tread, low ground pressure | Landscaping, golf courses, lawns |

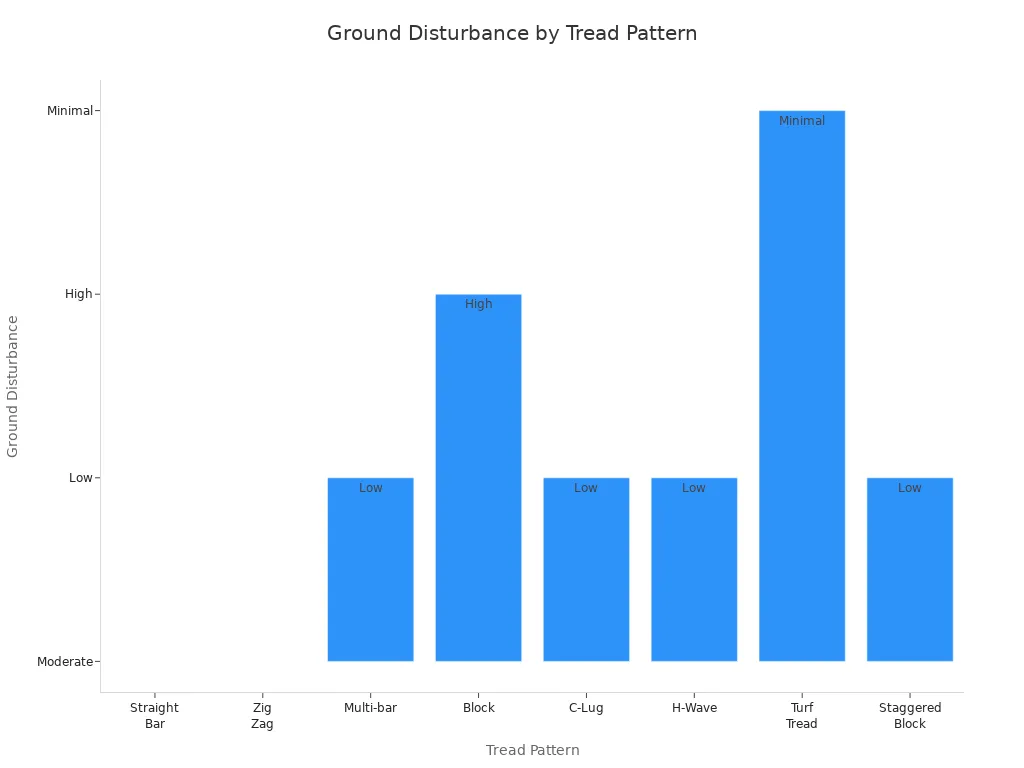

Different tread patterns affect how the machine moves and protects the ground. For example, straight-bar and zig zag patterns give strong traction in mud or snow. Multi-bar and turf treads provide a smoother ride and protect delicate surfaces.

Note: Choosing the right tread pattern helps reduce soil damage and improves operator comfort.

Application-Specific Track Designs

Some tracks are made for special jobs. Application-specific tracks use reinforced sidewalls, steel cords, and advanced rubber compounds. These features increase durability and resist cuts or heat. Wide tracks lower ground pressure and help machines float on soft ground like clay or sand. Narrow tracks give better grip on tough terrain.

- Multi-bar, zig-zag, and block patterns match different job needs.

- General-purpose tracks have basic designs for everyday work.

- Application-specific tracks last longer and perform better in harsh conditions.

Skid Steer Rubber Tracks with the right design help machines work safely and efficiently. Selecting the correct track for each job site reduces downtime and keeps projects on schedule.

Choosing Skid Steer Rubber Tracks for Your Equipment

Key Factors for Selection

Selecting the right tracks for a skid steer loader involves several important factors. Equipment owners should look at these points:

- Track width: Wider tracks help machines float on soft or loose ground. They lower ground pressure and prevent sinking. Narrower tracks give more grip on hard or rocky surfaces.

- Tread pattern: The right tread pattern matches the job. Straight bar treads work well on mixed terrain. Zig-zag or block patterns give strong traction in mud or loose soil. Turf-friendly treads protect grass and landscaping.

- Rubber compound: Different rubber blends offer special features. Some resist cuts and chunks, while others last longer on rough ground. High-quality compounds improve durability and performance.

- Track size compatibility: Owners need to check the width, pitch, and link count. Tracks must fit the machine’s undercarriage.

- OEM vs aftermarket: Some owners choose original equipment tracks. Others pick aftermarket options for cost or availability.

- Proper tension and undercarriage fit: Tracks must stay tight and fit well to avoid wear and damage.

A John Deere 317G with 12.6-inch tracks puts about 25% more pressure on the ground than with 15.75-inch tracks. This shows how track width changes performance.

Matching Tracks to Job Site Conditions

Job site conditions affect which tracks work best. Owners should consider these guidelines:

- Wider tracks work better on mud, snow, or soft ground. They spread weight and stop the machine from sinking.

- Aggressive C-pattern treads handle rocky or rough terrain. Zig-zag patterns grip well on ice, snow, and mud. Block treads last longer on hard or demolition sites but may not grip as well.

- High-grade rubber compounds and steel cords make tracks stronger. These features help in tough environments like construction or forestry.

- Reinforced sidewalls protect against roots, stumps, and rocks.

- Regular cleaning and inspection keep tracks working longer.

Choosing Skid Steer Loader Tracks with the right width, tread, and material helps machines perform well in any condition.

Product Features of Skid Steer Rubber Tracks

Rubber Compound and Durability

The rubber compound in modern tracks uses a special blend of natural and synthetic materials. This blend gives the tracks strength, flexibility, and resistance to harsh environments. Manufacturers add different ingredients to improve performance:

- Natural rubber adds elasticity and helps the track resist tearing.

- Synthetic rubbers, such as SBR and EPDM, increase abrasion and heat resistance. These materials help the track last longer on rough or hot surfaces.

- Carbon black makes the rubber harder and protects it from sunlight and ozone.

- Silica improves grip on wet ground and helps the track stay cool.

- Sulfur creates strong links between rubber molecules, making the track tough and elastic.

- Antioxidants and antiozonants slow down aging and prevent damage from weather.

- Plasticizers and oils keep the rubber flexible, even in cold weather.

The right mix of these materials allows the track to handle heavy loads and rough terrain. High-quality rubber compounds also form a strong bond with the steel inside the track. This bond prevents the rubber from peeling away and keeps the track working longer.

Note: Tracks with advanced rubber compounds last longer and perform better in tough conditions.

Steel Chain Links and Bonding Technology

Steel chain links form the backbone of the track. These links use drop-forged, heat-treated steel alloys for extra strength. The steel structure gives the track the power to carry heavy machines without stretching or breaking.

- Continuous steel cords run through the track, spreading out the force and stopping weak spots from forming.

- Special coatings on the steel protect it from rust and water damage.

- Textile wrapping between steel cords keeps everything in place and stops the cords from snapping.

- Advanced bonding agents seal the rubber to the steel, making the track waterproof and strong.

This combination of steel and bonding technology keeps the track in shape, even after long hours of work. The track stays aligned with the machine’s wheels and rollers, reducing the risk of slipping or coming off. These features help the track last longer and work safely in all kinds of weather.

Maintenance Tips for Skid Steer Rubber Tracks

Track Tension and Adjustment

Proper track tension keeps the machine running smoothly. Operators should check track tension daily and adjust it according to the manufacturer’s instructions. Tracks that are too loose can slip off or let debris inside, causing damage. Tracks that are too tight can tear or put extra strain on the drive motor. Monthly adjustments using mechanical tensioners help maintain the right tightness. Regular checks of rollers and idlers also support smooth operation and prevent uneven wear.

Tip: Always follow the equipment manual for tension settings. This practice extends track life and reduces repair costs.

Cleaning and Inspection

Clean tracks last longer and perform better. Operators should remove mud, rocks, and debris after each use. A stiff brush or low-pressure water works best. High-pressure washers can force dirt deeper into the track. Daily cleaning around the roller wheels prevents abrasive damage. Inspections should focus on cuts, cracks, and tread depth. Operators should also check for objects stuck in the tracks and remove them right away. Storing equipment on flat, clean surfaces protects tracks from damage.

- Clean tracks and undercarriage daily.

- Inspect for deep cuts, missing chunks, or worn lugs.

- Check drive wheels and sprockets for wear.

Signs Tracks Need Replacement

Worn tracks can cause safety risks and machine downtime. Operators should look for these signs:

- Cracks, missing lugs, or exposed steel cords on the track surface.

- Tread depth less than one inch, which reduces traction and stability.

- Sprocket teeth that look hooked or pointed, or frequent derailments.

- Tracks that stretch too much or feel too tight, causing operational issues.

Prompt replacement of damaged tracks keeps the machine safe and productive.

- Operators report better traction, stability, and smoother operation on tough terrain.

- Proper track selection and maintenance increase uptime and reduce repair costs.

- High-quality rubber tracks last longer and require fewer repairs, saving money over time.

- Upgrading tracks improves equipment performance and operator satisfaction.

FAQ

What makes rubber tracks better for soft ground?

Rubber tracks spread the machine’s weight. This helps the loader move over mud or sand without sinking. Operators see less ground damage and better traction.

How often should operators check track tension?

Operators should check track tension every day before use. Proper tension keeps the tracks safe and helps them last longer.

Can rubber tracks work on pavement?

Yes. Rubber tracks protect pavement from scratches. They also reduce noise and vibration. Many landscaping and construction crews use them in urban areas.

Post time: Jul-10-2025