Over the years, ASV Rubber Tracks have changed how people tackle tough jobs. They bring strong performance and steady reliability to every project. Many professionals in construction, agriculture, and landscaping trust these tracks. Ongoing research helps the technology stay ahead and meet new challenges.

Key Takeaways

- ASV Rubber Tracks use advanced materials and smart designs to deliver longer life, better grip, and smoother rides across tough terrains.

- Innovations like the Posi-Track system and reinforced internal structures reduce repairs, save fuel, and extend work seasons for users.

- Strong quality control, comprehensive warranties, and excellent customer support ensure reliable performance and peace of mind for operators.

ASV Rubber Tracks: Key Milestones and Innovations

Early Generations and Foundational Designs

The story of ASV Rubber Tracks began with simple but strong designs. Early tracks used basic rubber blends and straightforward patterns. These first models helped machines move over soft ground without getting stuck. Farmers and builders liked how these tracks protected the soil and made work easier.

As time passed, engineers wanted more from their tracks. They started to use better rubber and added new shapes to the tread. These changes gave machines better grip and made the tracks last longer. The company also built a strong technical team and set up careful testing for every track. They checked each step, from raw materials to the finished product. This focus on quality helped ASV Rubber Tracks stand out from the start.

Tip: Early ASV Rubber Tracks made a big difference for people who needed to work in muddy or rough places. They helped machines keep moving when wheels would spin or sink.

Introduction of Posi-Track and Patented Undercarriage Systems

A big leap came when ASV introduced the Posi-Track system. This new idea used a special undercarriage that spread the machine’s weight over a larger area. The result? Machines could glide over soft ground without leaving deep ruts. The patented undercarriage also used rubber-on-rubber contact, which made rides smoother and reduced wear.

Engineers added high-strength polyester wires inside the tracks. These wires made the tracks stronger and less likely to break. The company also started using a fully suspended frame. This frame helped the machine stay steady, even on bumpy ground. With these changes, ASV Rubber Tracks became known for comfort, strength, and long life.

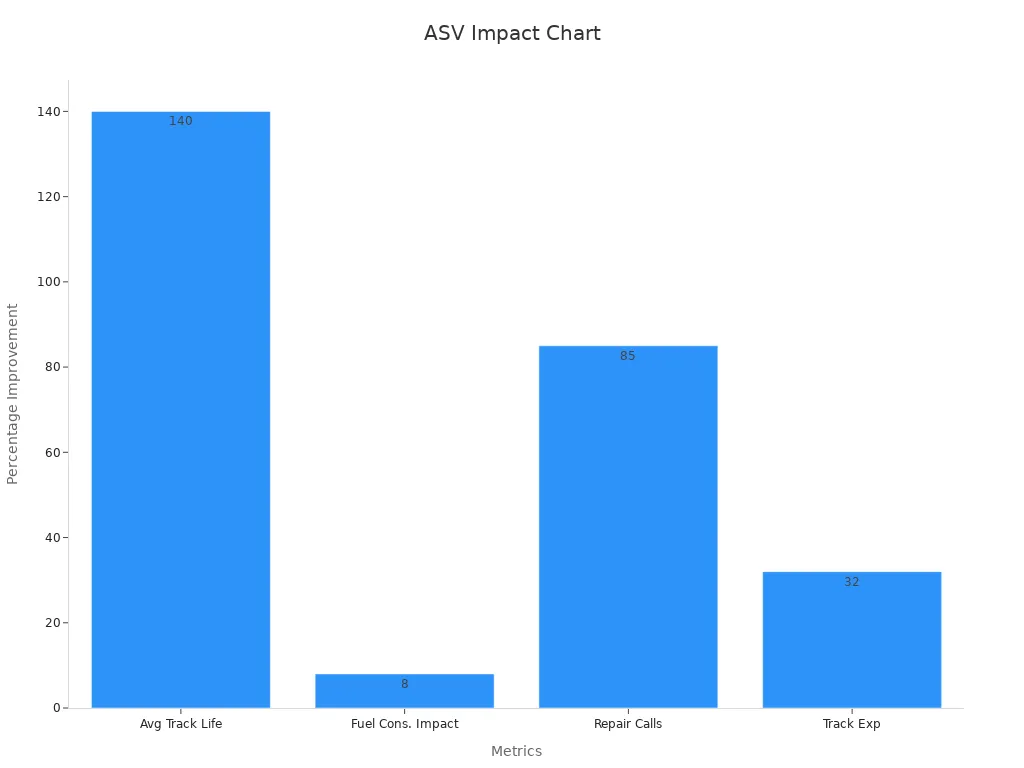

Let’s look at how these innovations changed performance:

| Metric | Traditional System | ASV Tracks (Innovation Impact) |

|---|---|---|

| Average Track Life | 500 hours | 1,200 hours (140% increase) |

| Fuel Consumption | N/A | 8% reduction |

| Emergency Repair Calls | N/A | 85% decrease |

| Total Track-Related Expenses | N/A | 32% reduction |

| Workable Season Extension | N/A | 12 days extension |

These numbers show how ASV Rubber Tracks help users save money and time. Fewer repairs mean less downtime. Longer track life means more work gets done before replacement. The Posi-Track system and patented undercarriage set a new standard for tracked machines.

ASV Rubber Tracks: Advanced Materials and Construction

Premium Rubber Compounds and Synthetic Blends

ASV Rubber Tracks use a special blend of natural and synthetic rubber. This mix gives the tracks more strength and flexibility. Engineers add a high volume of carbon black, which makes the tracks more resistant to heat and cuts. These features help the tracks last longer, even on rough or abrasive surfaces.

Many studies show that advanced rubber compounds make a big difference. For example:

- Tracks made with premium rubber can last over 1,000 hours, while basic tracks last only 500-700 hours.

- Special tread patterns give better grip on all types of ground, which helps machines use less power.

- The rubber stays flexible in hot or cold weather, so the tracks work well all year.

- A wider track spreads out the machine’s weight, which protects the ground and keeps soil from getting packed down.

- The rubber also absorbs bumps and noise, making the ride smoother for the operator.

Note: These advanced materials help reduce the need for repairs and lower the total cost of ownership.

Reinforced Internal Structures and Steel Cable Technology

Inside each track, engineers use strong steel cables and layers of tough materials. These cables are wound in a special way and covered with vulcanized rubber. This design keeps moisture out and protects the cables from rust and damage.

Tests show that reinforced structures make the tracks stronger and more reliable. The steel cables help the tracks handle heavy loads and tough jobs without breaking. Reinforced layers also stop cracks from spreading and keep the tracks working longer. This smart construction means ASV Rubber Tracks can handle hard work in many industries.

ASV Rubber Tracks: Engineering and Design Advancements

Optimized Tread Patterns for Maximum Traction

Engineers at ASV know that every job site is different. They design tread patterns to help machines grip the ground in all kinds of conditions. Some treads have deep lugs that dig into mud or loose dirt. Others use a zigzag shape to keep machines steady on rocks or gravel. These patterns help machines move forward without slipping.

Operators notice the difference right away. Machines with the right tread pattern can climb hills, cross wet fields, or work on hard pavement. The tread also helps protect the ground. It spreads out the machine’s weight, so there are fewer ruts or marks left behind.

Tip: Choosing the right tread pattern can make a big difference in how much work gets done each day.

Open-Rail and Drive-Sprocket Undercarriage

The undercarriage is the part of the machine that holds the tracks in place. ASV Rubber Tracks use an open-rail design. This design lets dirt, rocks, and debris fall out instead of getting stuck. Machines keep running smoothly, even in tough conditions.

The drive-sprocket system helps the tracks move with less effort. It grabs the track firmly, so there is less slipping or jumping. This means less wear and tear on the tracks and the machine. Operators spend less time cleaning out the undercarriage and more time working.

Note: These smart engineering choices help ASV Rubber Tracks last longer and work better in every season.

ASV Rubber Tracks: Durability and Longevity Features

Wear-Resistant Technologies and Carbon Black Integration

Engineers want tracks that last longer and work harder. They use advanced rubber compounds with special carbon black blends. This makes the tracks tough against cuts, heat, and rough ground. The tracks can handle more hours on the job, sometimes going from 500 to over 1,200 hours before needing replacement. That means less downtime and fewer repairs for operators.

- Tracks with these wear-resistant technologies show a 140% increase in service life.

- Replacement rates drop by more than half, saving time and money.

- Operators notice fewer cracks and tears, even in harsh conditions.

- The tracks also perform better in muddy or abrasive areas, so machines can work longer each season.

Carbon black helps the rubber stay strong and flexible. It also improves how the tracks handle friction and wear during tough jobs. This careful mix of materials keeps the tracks working well, even when the ground gets rough.

Enhanced Debris Management and Corrosion Prevention

Dirt and rocks can cause problems for tracks. Engineers design the tracks with open-rail systems that let debris fall away. This keeps the undercarriage clean and helps the machine run smoothly. The tracks use a single-cure process, which removes weak spots and makes them stronger.

- Over 150,000 hours of testing prove the tracks can handle tough environments.

- Seven layers of special materials protect against cuts, stretching, and punctures.

- The tracks do not use steel cords, so there is no risk of rust or corrosion.

- Pre-stretched tracks keep their shape and length, even after long use.

These features help the tracks last longer and stay reliable. Operators spend less time on maintenance and more time getting work done.

ASV Tracks: Practical Benefits for Users

Superior Traction and Stability Across Terrains

Operators often face changing ground conditions. Some days bring mud, others loose gravel or soft turf. Engineers design tread patterns to help machines grip every surface. Deep lugs dig into soft soil, while zigzag shapes hold firm on rocky ground. This means machines can climb hills, cross wet fields, or work on pavement without slipping. The tracks also spread out the machine’s weight, so there are fewer ruts and less damage to the ground.

Tip: Choosing the right tread style—aggressive, standard, or turf—helps match the track to the job and keeps machines moving smoothly.

Reduced Downtime and Maintenance Requirements

Longer-lasting tracks mean less time in the shop and more time on the job. Operators notice fewer breakdowns and repairs. Maintenance logs show clear improvements:

- Track life jumps from 500 to over 1,200 hours.

- Replacement drops from 2-3 times per year to just once.

- Emergency repair calls fall by 85%.

- Total track-related expenses go down by 32%.

| Metric | Before ASV Tracks | After ASV Tracks | Improvement |

|---|---|---|---|

| Average Track Life | 500 hours | 1,200 hours | Increased by 140% |

| Annual Replacement Frequency | 2-3 times/year | 1 time/year | Decreased by 50-67% |

| Total Track-Related Expenses | N/A | 32% decrease | Significant cost savings |

Versatility for Multiple Industry Applications

These tracks work well in many industries. Construction crews, farmers, and landscapers all benefit from their features. The tracks lower ground pressure by up to 75% compared to wheels, which protects soil and lawns. Specialized tread patterns give strong traction and stability, even in mud or wet fields. The rubber absorbs shocks, making long days more comfortable for operators. Tracks last over 1,000 hours, so users spend less on replacements. Weather resistance and anti-corrosion treatments keep machines running in every season.

Note: Matching the track type to the job ensures the best performance and longest life.

ASV Rubber Tracks: Quality Assurance and Support

Comprehensive Warranty and Customer Support

Customers want to know their equipment is protected. That’s why the company offers a comprehensive warranty and strong customer support. Many users see real benefits from this support. For example, Urban Development Partners noticed their track life jump from about 500 to over 1,200 hours. Davidson Family Farms extended their workable season by almost two weeks. Greenscape Solutions saw zero mid-job failures after switching to premium tracks.

Here’s a look at how the warranty and support help different users:

| Customer / Case Study | Warranty Duration | Key Outcomes |

|---|---|---|

| Urban Development Partners | 6-18 months | Track life up to 1,200+ hours, fewer replacements, 85% fewer repair calls |

| Davidson Family Farms | 6-18 months | 12 more working days, less fuel used, better performance in muddy fields |

| Greenscape Solutions | 6-18 months | Track life up to 1,800+ hours, no failures during jobs, better return on investment |

These results show that the warranty and support team help customers save money and avoid downtime. Friendly technical support and easy access to replacement parts keep machines running longer.

ISO9001:2015 Quality Management and Testing Systems

The company takes quality seriously. They follow strict international standards to make sure every track meets high expectations. Their quality management system matches ISO9001:2015 standards. This means they check every step, from raw materials to finished products.

- The company holds certifications like ISO9000, CE markings, and ASTM standards.

- They use tests for abrasion resistance, tensile strength, and heat tolerance.

- Test reports and third-party reviews confirm the tracks’ durability.

- Customers get proof of quality with every purchase.

- The company offers replacement parts and technical help to support users.

These steps show a strong commitment to quality and customer satisfaction. Operators can trust that every track has passed tough tests before it reaches the job site.

ASV keeps pushing track technology forward. Their team uses new materials and smart designs. Users see better performance and longer-lasting tracks. Many industries trust these products for tough jobs. ASV stands behind every track with strong support and quality checks. They keep raising the bar for reliability.

FAQ

How long do ASV rubber tracks usually last?

Most users see track life between 1,000 and 1,200 hours. Some even get more, depending on the job and how they care for the tracks.

Tip: Regular cleaning and inspections help tracks last longer.

Can ASV loader tracks handle different weather conditions?

Yes, ASV rubber tracks work well in hot, cold, wet, or dry weather. The special rubber blend keeps them flexible and strong all year.

What makes ASV rubber tracks different from standard tracks?

ASV tracks use premium rubber, reinforced steel cables, and advanced tread patterns. These features give better traction, longer life, and less downtime for users.

Post time: Jun-18-2025