High-Quality China Rubber Robot Tracks from Leading Manufacturer

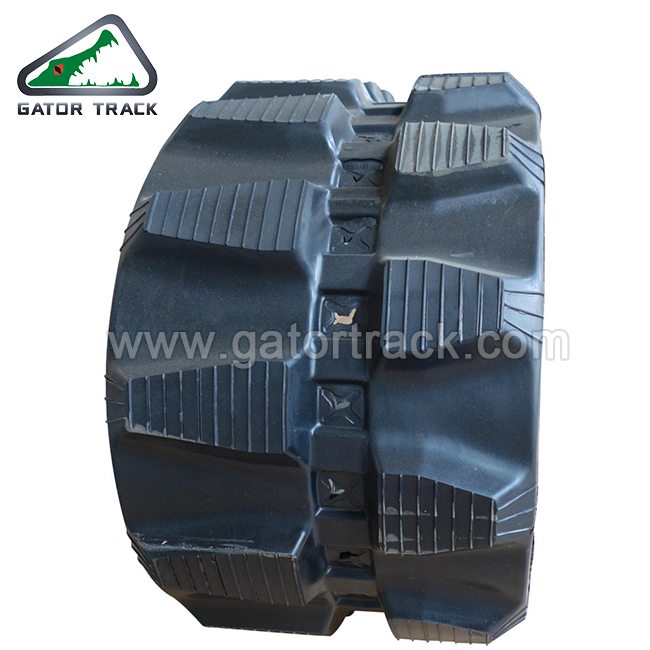

When it comes to robust and reliable movement solutions, my experience with China rubber robot tracks has been outstanding. As a manufacturer, I know the importance of high-quality materials and innovative design in ensuring optimal performance. These tracks are built to withstand various terrains and conditions, offering exceptional traction and durability for any robotic application. I’ve seen firsthand how well these tracks perform in different settings—from industrial use to hobby robotics. The flexibility and strength of the rubber material allow for smooth operation, minimizing wear and tear on your machinery. Plus, sourcing directly from a trusted manufacturer in China can lead to significant cost savings without compromising quality. Whether you’re developing automation projects or looking to enhance your existing robots, these rubber tracks provide the reliability and efficiency needed to elevate your operations. Let’s keep your robots moving forward with the best tracks available!

China Rubber Robot Tracks Application Factory

In recent years, the demand for innovative and versatile solutions in the manufacturing sector has surged, particularly in the realm of robotics. Among these, rubber robot tracks have emerged as a significant asset for various applications, providing enhanced mobility and stability for robotic systems across different environments. These tracks are essential for navigating challenging terrains, ensuring that robots can perform tasks efficiently, whether in factories, warehouses, or outdoor settings. With advancements in materials and engineering, high-quality rubber tracks are designed to offer superior grip, durability, and resistance to wear and tear. The ability to absorb shocks and vibrations allows robots to maintain precision even in dynamic situations, making them ideal for tasks ranging from assembly line operations to logistics and heavy lifting. As more industries adopt automation, investing in reliable rubber tracks for robotics becomes critical for improving productivity and reducing operational costs. For global procurement professionals seeking to enhance their robotics capabilities, exploring the latest innovations in rubber robot tracks is essential. The integration of these advanced solutions can lead to significant improvements in operational efficiency, ultimately driving competitiveness in the market. With a focus on quality and performance, sourcing top-tier rubber tracks will ensure that businesses can fully harness the potential of robotic automation.

China Rubber Robot Tracks Application Factory

| Application Area | Robot Model | Operation Type | Efficiency (units/hour) | Power Consumption (kW) |

|---|---|---|---|---|

| Tire Production | RoboTread X1 | Cutting and Shaping | 200 | 5.5 |

| Industrial Rubber Parts | RoboFlex A2 | Molding | 150 | 4.0 |

| Automotive Rubber Sealing | SealBot Z3 | Assembly | 180 | 6.0 |

| Rubber Flooring | FloorMate Q4 | Installation | 100 | 3.5 |

| Rubber Gaskets | GasketPro M5 | Cutting | 120 | 4.5 |

Related Products