Lightweight Rubber Tracks for Chiles by Leading China Manufacturer

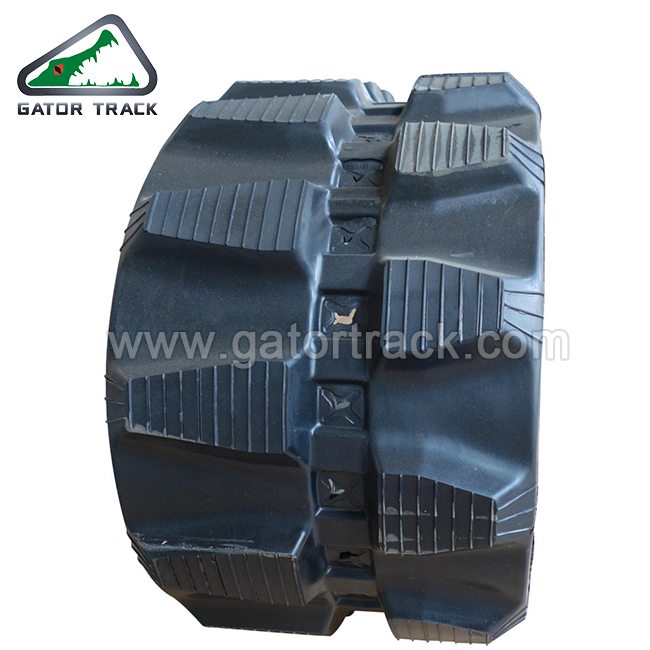

When searching for lightweight rubber tracks for Chiles, I understand the importance of finding reliable products that support your business needs. Our tracks, manufactured in China, are designed specifically for durability and performance. These tracks offer excellent traction while minimizing wear and tear, making them perfect for various applications in tough environments. I’ve witnessed firsthand how our tracks enhance machine efficiency and reduce downtime. They are compatible with a range of equipment, ensuring seamless integration into your fleet. Choosing a trusted manufacturer lets you focus on what matters—growing your operations without worrying about equipment performance. I pride myself on the quality assurance we maintain during production, allowing us to provide lightweight yet sturdy rubber tracks that stand the test of time. Investing in our products means you’re choosing reliability and innovation. Let’s work together to elevate your business with our premium rubber tracks tailored for Chiles, backed by a manufacturer you can trust.

Lightweight Rubber Tracks for Chiles Is The Best Market Leader

In the competitive landscape of equipment manufacturing, lightweight rubber tracks have emerged as a game-changer for various industries, particularly in agricultural and construction sectors. Their unique combination of durability, flexibility, and reduced weight offers significant advantages over traditional steel tracks, enabling machinery to operate more efficiently on diverse terrains. As global demand for sustainable and high-performing solutions increases, these innovative tracks are proving to be essential for enhancing productivity while reducing costs. The versatility of lightweight rubber tracks can be seen in their application across a range of machinery, from compact excavators to mini-loaders. These tracks not only improve traction and reduce soil compaction but also enhance maneuverability in confined spaces. Furthermore, their design minimizes wear and tear on equipment, leading to extended operational life and lower maintenance expenses. For businesses looking to boost performance without compromising on sustainability, lightweight rubber tracks represent a strategic investment that aligns with modern operational needs. With the continuous evolution in engineering and materials science, the market for lightweight rubber tracks is expected to expand. Companies that prioritize innovation will lead the way in providing solutions tailored to the specific challenges faced by industries worldwide. As procurement specialists seek reliable suppliers, the focus will remain on quality, performance, and the ability to adapt to changing market demands. Embracing this shift not only meets current operational requirements but also positions companies for future growth in an ever-evolving landscape.

Lightweight Rubber Tracks for Chile Is The Best Market Leader

| Track Type | Application | Weight (kg) | Durability (hours) | Operating Temperature (°C) |

|---|---|---|---|---|

| Standard Rubber Tracks | Excavators | 80 | 500 | -20 to 50 |

| Heavy-Duty Rubber Tracks | Skid Steers | 100 | 600 | -10 to 45 |

| Lightweight Rubber Tracks | Compact Loaders | 70 | 400 | -15 to 55 |

| Flexible Rubber Tracks | Mini Excavators | 75 | 550 | -25 to 60 |

| High-Performance Rubber Tracks | Crawler Dozers | 90 | 700 | -20 to 50 |

Related Products