Ruber Tracks Excavator from China - Leading Manufacturer Options

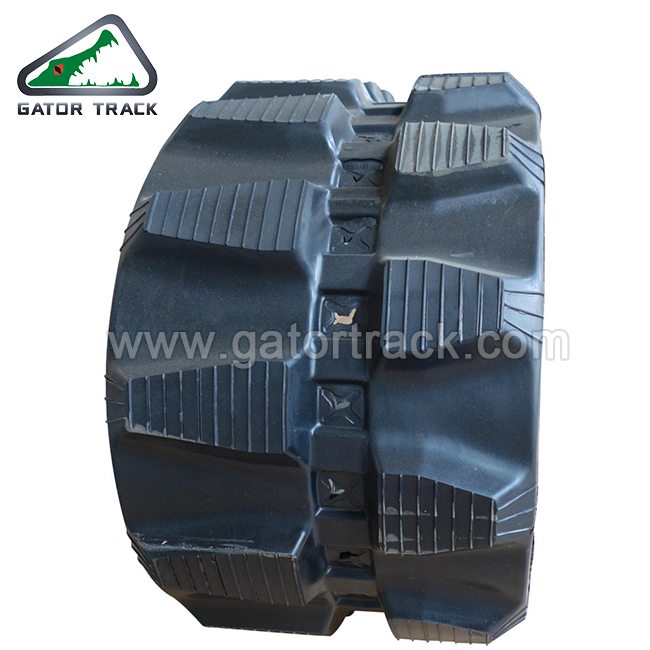

When I first came across Ruber Tracks Excavator, I knew I found a game-changer for our heavy machinery needs. This product not only showcases incredible durability but also offers unparalleled performance tailored for various terrains. Sourced directly from a reputable China manufacturer, these tracks are engineered to ensure longevity and efficiency, making them an ideal investment for any construction business looking to optimize its equipment. Whether you're working on urban projects or rough landscapes, these tracks provide the grip and stability you need. I’ve been impressed with their reliable traction and resistance to wear, which significantly reduces downtime. Plus, as a B2B purchaser, knowing I’m dealing with quality and cost-effectiveness is crucial. If you're aiming to upgrade your excavator’s capabilities while partnering with a trusted supplier, Ruber Tracks Excavator is definitely a solution worth considering.

Ruber Tracks Excavator to French Industry Leaders Industry Giant

In the dynamic landscape of heavy machinery, the integration of advanced technology and sustainability has become pivotal for industry leaders. Recently, a notable trend has emerged with the adoption of rubber tracks by major excavator manufacturers. These innovations are not only enhancing operational efficiency but also addressing environmental concerns that are rising among global procurement teams. Rubber tracks provide substantial advantages compared to traditional steel tracks. They minimize ground disturbance, reduce noise pollution, and improve fuel efficiency, making them an ideal choice for projects in sensitive environments. As leaders in the French industry seek to align with global sustainability goals, the adoption of machinery equipped with rubber tracks could significantly enhance their operational capabilities while demonstrating a commitment to eco-friendly practices. Furthermore, the versatility of excavators fitted with rubber tracks allows for seamless transitions across various terrains, from urban construction sites to rural infrastructure projects. This adaptability is essential for procurement professionals looking to optimize their fleet while ensuring compliance with stringent regulations. With the global shift towards innovative technologies in construction, rubber tracks are quickly becoming a key component in the machinery of the future, enabling industry giants to lead the charge towards a more sustainable and efficient operational model.

Ruber Tracks Excavator to French Industry Leaders Industry Giant

| Industry Type | Excavator Model | Track Type | Strength Rating (tons) | Usage (hours) |

|---|---|---|---|---|

| Construction | Model A | Rubber | 10 | 200 |

| Mining | Model B | Steel | 15 | 150 |

| Agriculture | Model C | Rubber | 8 | 300 |

| Demolition | Model D | Rubber | 12 | 250 |

Related Products