I understand the critical need for reliable components. You can find compatible Dumper Rubber Tracks readily available for your Thwaites, Morooka, Yanmar, and Wacker Neuson dumpers. We ensure these tracks meet precise specifications, providing the robust foundation your equipment demands. This availability helps maintain operational continuity on your job sites.

Key Takeaways

- High-quality rubber tracks make dumpers work better. They last longer and save money.

- Measure track width, pitch, and link count. This ensures the right fit for your dumper.

- Check tracks daily and keep them clean. This helps them last longer and work safely.

Understanding Dumper Rubber Tracks

What Defines Quality Dumper Rubber Tracks?

When I look at what makes a dumper rubber track truly high-quality, I consider several key factors. It starts with the material composition. Premium rubber compounds and a thick carcass are essential for maximum service life and predictable durability. I know these tracks are constructed from robust rubber compounds, often reinforced with steel cables or fibers. Using non-recycled rubber is crucial; it ensures the material’s intact chemical properties, unlike recycled options with reduced wear resistance. Manufacturers also incorporate special additives like anti-ozone and anti-aging chemicals, specialized coupling agents, and high-performance additives. Some formulations include over 30 different chemical ingredients, far more than competitors, to fine-tune the rubber for optimal performance. High-quality tracks also feature steel cords or fabric layers for enhanced strength, preventing delamination, and a well-engineered pitch and profile to reduce noise and vibration.

Why Choose Rubber Over Steel Dumper Tracks?

I often recommend rubber tracks over steel for several compelling reasons. Rubber tracks offer excellent flotation and traction across soft ground, steep grades, and slippery conditions. Their low ground pressure makes them ideal for sensitive terrain like wetlands or landscaped areas, minimizing damage. They provide superior traction on mud, snow, and steep inclines, allowing for all-terrain flexibility and year-round work in more environments. Furthermore, rubber tracks are the best option for crossing hard surfaces such as pavement or sidewalks, where steel tracks can cause significant damage. A notable advantage I observe is the significant reduction in noise; dumper rubber tracks can reduce noise by up to 20% compared to steel tracks, contributing to a quieter and more compliant work environment.

Dumper Rubber Tracks Compatibility Across Brands

I know that while many dumper manufacturers exist, the underlying principles for track compatibility often remain consistent. Understanding these brand-specific nuances helps me guide you toward the best track choices for your equipment.

Thwaites Dumper Tracks: Key Considerations

When I look at Thwaites dumpers, I see robust machines designed for demanding construction environments. For Thwaites Dumper Rubber Tracks, I prioritize durability and traction. These machines often operate on uneven ground, so the track’s lug pattern and carcass strength are crucial. I consider the specific model and its typical operating conditions. For instance, a track designed for heavy-duty site work will differ from one used primarily on softer ground. I always ensure the track’s dimensions precisely match the dumper’s undercarriage specifications to guarantee optimal fit and performance.

Morooka Dumper Rubber Tracks: Maximizing Performance

Morooka dumpers are synonymous with heavy-duty, all-terrain capability. When I select Morooka Dumper Rubber Tracks, my focus is on maximizing their already impressive performance. These tracks need to withstand significant loads and provide superior flotation and grip on challenging surfaces like mud, sand, or steep inclines. I often look for tracks with deep, aggressive tread patterns and reinforced internal structures. This ensures the tracks can handle the power output of Morooka machines and maintain stability and traction under extreme conditions, which is vital for their specialized applications.

Yanmar Dumper Rubber Tracks: Precision and Reliability

Yanmar dumpers are known for their compact size, precision, and unwavering reliability. For Yanmar Dumper Rubber Tracks, I emphasize tracks that offer smooth operation and consistent performance. These machines often work in tighter spaces where maneuverability is key. I look for tracks that minimize vibration and provide excellent grip without causing excessive ground disturbance. The quality of the rubber compound and the integrity of the internal steel cords are paramount. This ensures the tracks contribute to the machine’s overall reliability and precise control, which I find essential for Yanmar equipment.

Wacker Neuson Dumper Rubber Tracks: Versatility on Site

Wacker Neuson dumpers offer incredible versatility, adapting to various tasks and terrains on a job site. When I choose Wacker Neuson Dumper Rubber Tracks, I consider this adaptability. The tracks need to perform well across a range of surfaces, from concrete to soft soil. I often recommend tracks that strike a balance between aggressive traction and minimal surface damage. This versatility means the tracks must be durable enough for tough conditions but also gentle enough for finished surfaces. I ensure the track design supports the dumper’s ability to transition smoothly between different work environments.

Universal Principles for Dumper Rubber Tracks Compatibility

I find that despite brand differences, universal measurement standards govern Dumper Rubber Tracks compatibility. When I determine if a track fits a machine, I rely on three critical measurements. For compact construction equipment, including dumpers, I measure the track’s width, typically in millimeters. I also measure the center-to-center distance between two drive links, which is known as the pitch. Finally, I count the total number of drive links present on the track.

The industry standard formula for measuring rubber track size, applicable across different brands for compatibility, is straightforward:

- Width (mm): This is the track’s overall width.

- Pitch (mm): This refers to the distance between the centers of consecutive drive lugs.

- Links (#): This is the total count of the internal teeth or links that engage with the machine’s sprocket.

These three values—width, pitch, and the number of links—are crucial. They form the basis for determining if any rubber track will correctly fit a specific dumper model, regardless of the manufacturer. I always verify these measurements to ensure a perfect fit and optimal machine performance.

Advantages of High-Quality Rubber Tracks for dumper

Enhanced Performance and Efficiency

I find that high-quality dumper rubber tracks significantly boost machine performance and efficiency. They offer superior traction and stability, allowing dumpers to operate effectively on diverse terrains. This means less slippage and more consistent power delivery. I see how key performance metrics demonstrate this enhanced efficiency:

| Performance Metric | Description | Efficiency Benefit |

|---|---|---|

| Traction Rating | Measures stopping ability on wet surfaces | Influences tread design and safety |

| Treadwear Rating | Predicts tire longevity | Longer-lasting tracks maintain high efficiency |

| Temperature Rating | Shows heat resistance | Better heat dissipation leads to less wear and increased durability |

| Rolling Resistance | Energy lost when rolling | Lower resistance results in fuel savings and improved efficiency |

Lower rolling resistance directly translates to fuel savings. Japanese construction firms report a 22% efficiency improvement in earthmoving tasks using automated rubber tracked dumpers. These machines also reduce ground pressure by up to 60%.

Extended Lifespan and Reduced Downtime

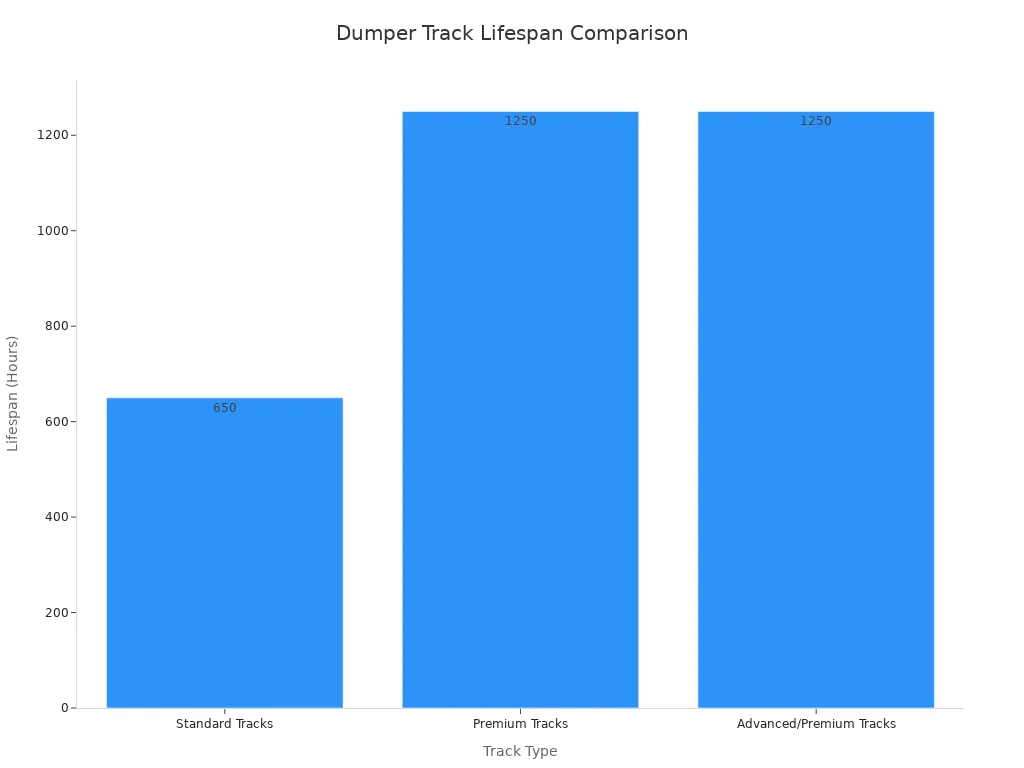

Investing in premium dumper rubber tracks extends their operational lifespan considerably. This directly reduces downtime for track replacements. Advanced dumper rubber tracks nearly double operational lifespan compared to standard tracks.

| Track Type | Lifespan (Hours) | Replacement Frequency (for 1,000 hours/year) |

|---|---|---|

| Standard Tracks | 500-800 | Every 6-9 months |

| Premium Tracks | 1,000-1,500+ | Every 12-18 months or longer |

Improved track designs extend track life by up to 140% and lower maintenance costs. They also provide up to 60% more grip due to specialized tread designs. This means operators gain more workable days each season, boosting productivity.

Operator Comfort and Safety Benefits

High-quality rubber tracks greatly improve operator comfort and safety. They absorb shocks from rough terrain, reducing vibration and jolts. This creates a smoother ride.

Operators often say that rubber tracks help them glide smoothly over rough terrain, making every job easier and more comfortable.

Laboratory tests show rubber-based track components provide much better shock absorption than traditional steel tracks. Drop hammer impact studies reveal rubber inclusions can reduce vertical acceleration by over 60%. This means less vibration reaches the operator. Rubber tracks also dampen sound, creating a quieter work environment. They can reduce noise by up to 18.6 dB compared to traditional tracks. This reduces operator fatigue.

High-quality tracks also enhance safety. They offer superior traction and stability on rough terrain. This prevents slippage and reduces the risk of getting stuck. Stability tests have shown a 15% lower roll-over rate compared to traditional steel tracks. This makes them a safer choice, especially on uneven ground and steep slopes.

Choosing the Right Dumper Rubber Tracks

Key Factors for Selecting Dumper Rubber Tracks

When I choose Dumper Rubber Tracks, I consider several crucial factors. The environment where the dumper operates plays a significant role. For instance, winter weather demands specific tread designs. I look for tracks with many edges to maximize traction on snow and ice. A self-cleaning design is also essential. This prevents snow from filling voids, which can lead to lost productivity, driving difficulties, and safety hazards.

Worksite debris is another critical consideration. Items like scrap wood, cinder blocks, bricks, stones, and rebar can cause impact damage and track failure. Debris getting between the undercarriage and tracks can lead to catastrophic damage. I always recommend clearing the worksite of such debris. This significantly extends track life.

Climate also influences my track selection. In frequently rainy climates, C-pattern tracks are suitable. For snow and ice, I find TDF (Technology Design Formulation) tread ideal. It effectively grips snowy and icy surfaces without digging in, preventing slipping and aiding driving.

Terrain and ground conditions are equally important. For soft ground, I recommend wider tracks. They distribute equipment weight, minimize disturbance, and protect the terrain. For gravel, sand, solid dirt, or turf, hex tread patterns offer durability and versatility. They provide a comfortable ride and leave minimal markings on lawns and grassy areas. However, I advise avoiding them in excessively wet conditions.

OEM vs. Aftermarket Dumper Rubber Tracks

I often weigh the options between OEM (Original Equipment Manufacturer) and aftermarket Dumper Rubber Tracks. OEM tracks come directly from the dumper’s manufacturer. They guarantee a perfect fit and often match the original specifications. I know they integrate seamlessly with the machine’s design.

Aftermarket tracks, on the other hand, come from independent manufacturers. They can offer significant cost savings. I find many aftermarket options provide comparable quality and performance to OEM tracks. However, I always advise careful research. I look for reputable aftermarket suppliers who use high-quality materials and manufacturing processes. Sometimes, aftermarket tracks even offer specialized designs or compounds that might better suit specific operating conditions than OEM options. The key is to ensure the aftermarket track meets or exceeds the original specifications for durability and performance.

Where to Find Reliable Dumper Rubber Tracks

Finding reliable Dumper Rubber Tracks is crucial for your dumper’s longevity and performance. I always start by looking for suppliers with a proven track record. Online retailers specializing in heavy equipment parts are a good resource. They often have extensive inventories and competitive pricing. I also check with local heavy equipment dealers. They can provide expert advice and often stock tracks for common dumper models.

When evaluating suppliers, I prioritize those who offer clear product specifications and customer support. I also look for certifications. Reliable dumper rubber track suppliers should possess ISO9001 certification. This standard indicates a commitment to quality management. It assures me that the supplier follows rigorous processes in manufacturing and quality control. This certification is explicitly mentioned in relation to dumper replacement rubber tracks, highlighting its relevance as a quality assurance measure. I believe choosing a supplier with this certification gives you confidence in the product’s quality and reliability.

Maintaining Your Dumper Rubber Tracks

Daily Checks and Routine Inspections

I always recommend daily checks for your dumper rubber tracks. This helps identify wear and damage early. I look for cuts, cracks, and exposed wires. I also check for any movement of metal imbeds. It is important to rinse off the track and undercarriage daily. This removes debris. If I see exposed cables, I clip them off with wire cutters. I also inspect for exposed metal imbeds outside the guide lugs. This indicates severe damage. I check for worn pads, loose bolts, and uneven wear on components. I also look for any oil leaks.

Proper Tensioning for Dumper Rubber Tracks

I know proper track tension is critical for dumper performance. It also extends track lifespan. Improper tensioning leads to premature wear. It causes inconsistent performance and can even lead to track failure. Loose tracks can cause idler fractures. They can also lead to misfeeding. This stresses the undercarriage. Overly tight tracks increase machine stress. They consume more fuel. They also risk bearing failure. Proper tension ensures smooth operation. It extends track lifespan.

Operating Practices to Extend Dumper Rubber Tracks Life

I advise specific operating habits to extend dumper rubber track life. I always make gradual or three-point turns. I avoid counter-rotating. This prevents unnecessary and uneven wear on the tracks. I drive slowly. I do not make sharp turns when operating on sloped terrain. I also avoid driving right along or over curbs. Hard surfaces can crack and rip rubber tracks. I avoid tight pivots and spins. These maneuvers cause excessive wear on undercarriage components.

I believe unlocking your dumper’s full potential starts with the right Dumper Rubber Tracks. Selecting and maintaining them correctly is vital. Understanding compatibility, recognizing their benefits, and performing proper maintenance are crucial steps. These actions ensure optimal performance and long-lasting durability for your equipment.

FAQ

How long do dumper tracks typically last?

I find standard tracks last 500-800 hours. Premium tracks can exceed 1,000-1,500 hours. This depends on usage and maintenance.

Why should I choose rubber tracks instead of steel tracks for my dumper?

I recommend rubber tracks for less ground damage, reduced noise, and better traction on varied surfaces. They also offer a smoother ride.

How do I ensure I buy the correct rubber tracks for my dumper?

I always measure three things: track width, pitch (distance between drive lugs), and the total number of links. These ensure a perfect fit.

Post time: Jan-04-2026