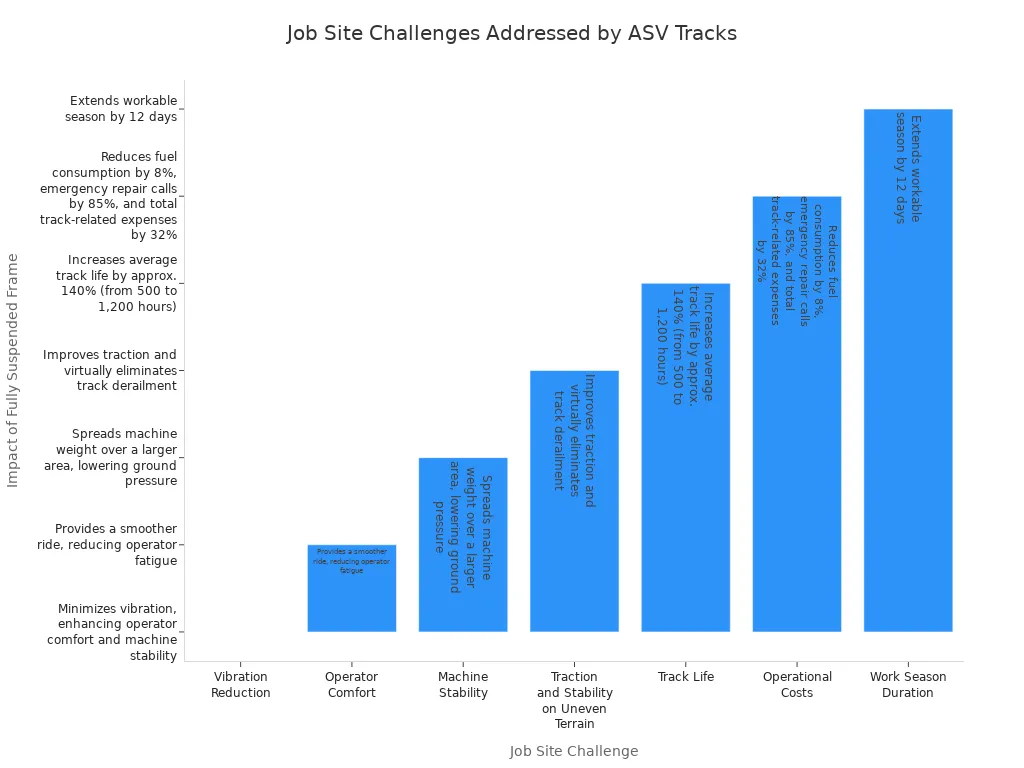

ASV rubber tracks turn every loader into a job site superstar. With a fully suspended frame and special rubber-on-rubber contact, operators enjoy a smooth ride and less machine wear. Check out these impressive stats:

| Metric | Value |

|---|---|

| Average Track Life | 1,200 hours |

| Ground Pressure | 4.2 psi |

| Emergency Repair Calls | 85% decrease |

Operators see longer track life, fewer repairs, and a boost in comfort—every shift feels like a win.

Key Takeaways

- ASV rubber tracks provide superior traction and stability, allowing loaders to work confidently on tough terrain like mud, snow, and slopes without slipping or sinking.

- These tracks reduce ground damage by spreading the loader’s weight evenly, lowering soil compaction and protecting lawns and crops, which saves time and money on repairs.

- The advanced design of ASV rubber tracks improves operator comfort by absorbing shocks and vibrations, reducing fatigue and machine wear, which boosts productivity and extends track life.

Performance Advantages of ASV Rubber Tracks

Superior Traction and Stability

ASV tracks turn every loader into a mountain goat. These tracks grip the ground with confidence, even when mud, snow, or loose gravel try to play tricks. The secret? A fully suspended frame and a clever rubber-on-rubber contact system. This combo absorbs shocks and keeps the loader steady, so operators can tackle hills, slopes, and bumpy ground without breaking a sweat.

- The Posi-Track system spreads the loader’s weight like peanut butter on toast—smooth and even. No more sinking or slipping.

- Flexible polyester cords inside the tracks let them hug the ground, following every dip and bump.

- Operators report feeling safer and more in control, which means they get more done in less time.

Note: ASV’s patented undercarriage technology gives loaders the power to work on soft, wet, or hilly terrain. The tracks keep the machine stable and safe, even when the job site looks like an obstacle course.

Reduced Ground Damage and Soil Compaction

Nobody likes a job site full of ruts and torn-up grass. ASV rubber tracks solve this problem with a gentle touch. Their special tread patterns and wide footprint spread out the loader’s weight, so the ground stays smooth and happy.

- These tracks can cut ground pressure by up to 75%. That means less soil compaction and fewer muddy messes.

- Landscapers and farmers love how the tracks protect delicate lawns and crops. No more angry calls about ruined turf!

- Operators notice fewer ruts and marks, even after a long day of work.

| Benefit | ASV Rubber Tracks Advantage |

|---|---|

| Ground Pressure | Up to 75% lower than steel tracks |

| Turf Damage | Up to 40% less with special tread design |

| Weight Distribution | Even, prevents sinking and rutting |

| Traction on Soft Ground | Excellent, reduces slippage |

ASV rubber tracks also help the planet. Better traction means less wasted fuel, which leads to lower emissions. The tracks last longer, so there’s less waste from replacements. That’s a win for both the job site and the environment.

Enhanced Operator Comfort and Ride Quality

Long days on a loader can feel like riding a roller coaster—unless the machine has ASV rubber tracks. The fully suspended frame and rubber-on-rubber contact design soak up bumps and jolts, turning rough rides into smooth cruises.

- Vibrations drop dramatically, so operators stay comfortable and alert.

- Less bouncing means less fatigue. Operators can focus on the job, not on sore backs or tired arms.

- Many call the suspension system a “game-changer.” They finish shifts feeling fresh, not frazzled.

Tip: The advanced design of ASV rubber tracks doesn’t just protect the operator. It also extends the life of the machine by reducing wear and tear. That means fewer repairs and more time getting work done.

ASV rubber tracks make every loader feel like a luxury ride. Operators enjoy better visibility, easier controls, and a seat that feels just right. With less stress and more comfort, productivity soars.

Durability and Maintenance of ASV Rubber Tracks

Advanced Materials and Construction

ASV rubber tracks do not settle for ordinary. They use a special blend of natural and synthetic rubbers, giving them the perfect mix of stretch and toughness. Most tracks in the industry rely on steel cords for strength. ASV rubber tracks take a different path. They use high-tensile poly-cords that run the length of the track. These cords act like a superhero’s cape—light, strong, and never rusty. The poly-cords let the tracks bend and flex over rocks, roots, and ruts without snapping or cracking.

The Posi-Track system brings even more magic. Each track gets its own drive motor and wide sprockets. Power moves smoothly from engine to ground. Roller wheels made from tough UHMW polyethylene, coated in rubber, spread the loader’s weight like a gentle giant. This design keeps the ride smooth and the tracks lasting longer. Operators notice the difference right away. The loader glides over rough ground, and the tracks shrug off sharp debris and wild weather.

Extended Track Life and Anti-Derailment Design

Long days on the job demand tracks that can keep up. ASV loader tracks deliver with a design built for the long haul. On dirt, these tracks can last up to 1,000 hours. Even on tough asphalt, they hold strong for 750-800 hours. That’s plenty of time to finish big projects without constant track changes.

| Track Brand/Type | Average Lifespan (hours) | Operating Conditions |

|---|---|---|

| ASV Tracks | 750-800 | Asphalt |

| ASV Tracks | Up to 1,000 | Primarily dirt |

| Komatsu Tracks | 1,500-2,000 | Various |

The secret to this staying power? ASV rubber tracks use high-strength polyester wires that run the length of the track. These wires stop the tracks from stretching out or popping off the loader. The tracks hug the ground, flexing with every bump and dip. This means fewer derailments and less time fixing problems. The all-terrain, all-season tread keeps the loader moving in mud, snow, or sand. Operators can work year-round, rain or shine, without worrying about the tracks giving up.

Note: The advanced rubber construction resists cracking in the cold and softening in the heat. Operators report fewer interruptions and safer job sites, even when the weather turns wild.

Easy Maintenance and Reduced Downtime

Nobody wants to spend their day fixing tracks. ASV rubber tracks make maintenance a breeze. Their tough rubber compounds and steel inserts fight off cuts and tears. This means fewer replacements and less time in the repair shop. Operators see real savings—replacement costs drop by 30%, and emergency repairs fall by 85%. That’s more time working and less time waiting.

Smart maintenance keeps the tracks rolling:

- Inspect for cracks, cuts, and wear to catch problems early.

- Check track tension every 30-50 hours to keep things snug and safe.

- Clean off mud, rocks, and ice every day to prevent buildup.

- Store tracks indoors or under covers to block out harsh sun and ozone.

- Trust the high-strength polyester wires to stop stretching and derailment.

ASV rubber tracks shine in every season. Their self-cleaning tread pushes out debris, so mud and snow never slow things down. Operators report smoother rides and fewer stops to fix stuck equipment. With good habits, loaders spend more time on the job and less time in the shop. That’s productivity you can count on.

ASV rubber tracks turn loader downtime into a thing of the past. Operators see big savings thanks to fewer derailments, less labor, and longer track life:

- Track derailment costs drop by $600 per event.

- Less time spent on tension adjustments.

- Internal drive sprockets mean cheaper, easier maintenance.

ASV rubber tracks come with a two-year, 2,000-hour warranty and a no-derailment guarantee, making customers smile. With smart features and advanced tech, these tracks keep loaders ready for the future.

FAQ

How long do ASV rubber tracks usually last?

Operators often see up to 1,200 hours of action. These tracks keep rolling through mud, snow, and sunshine. That’s a lot of job sites!

Tip: Regular cleaning helps tracks last even longer.

Can ASV rubber tracks handle rough weather?

Absolutely! ASV rubber tracks laugh at rain, snow, and heat. Their all-terrain tread keeps loaders moving, no matter what Mother Nature throws their way.

Do ASV rubber tracks fit all loader brands?

ASV rubber tracks work best with ASV loaders. Their special design matches the Posi-Track system. Other brands might not get the same superhero performance.

Post time: Jul-22-2025