Premium Mini Excavator Rubber Tracks from China Manufacturers for Norwegians

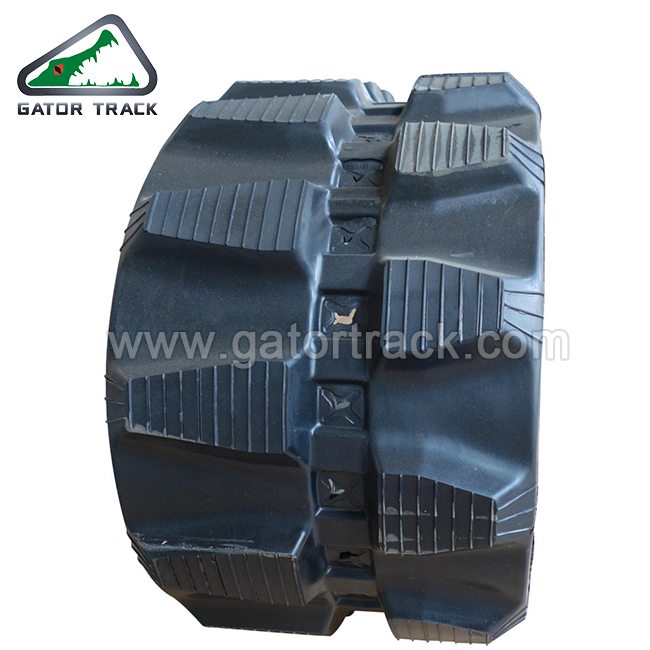

As a leading manufacturer from China, I'm excited to present our high-quality mini excavator rubber tracks specifically designed for the needs of industries in Norway. We understand the harsh conditions your machines operate in, and our tracks are built to withstand wear and tear while providing excellent traction on various terrains. Whether you're in construction or landscaping, having reliable tracks is crucial for efficiency and safety. Our tracks offer a seamless fit for most mini excavator models, ensuring you can maintain productivity without any downtime. Plus, with our competitive pricing, you can enhance your fleet without breaking the bank. If you're in the market for durable, reliable rubber tracks, I'm here to help you find the perfect solution tailored to your needs, right from the heart of China. Let’s work together to keep your equipment running smoothly and effectively in the beautiful Norwegian landscapes.

Mini Excavator Rubber Tracks to Norwegians Winning in 2025 Manufacturers You Can Rely On

As the demand for mini excavators continues to rise globally, the significance of high-quality rubber tracks cannot be overstated, particularly for suppliers catering to discerning markets like Norway. In the construction and landscaping industries, the efficiency and reliability of machinery play a pivotal role in project success. Therefore, selecting robust and durable rubber tracks is essential for manufacturers aiming to maintain their competitive edge in 2025 and beyond. Mini excavators are increasingly favored for their versatility, compact size, and ability to operate in confined spaces. However, the performance of these machines heavily relies on the quality of their rubber tracks. Reliable manufacturers are stepping up to meet the needs of global buyers by providing tracks designed to enhance traction, reduce vibration, and prolong longevity under various working conditions. Buyers seeking trustworthy partners should focus on suppliers with a proven track record of delivering high-performance rubber tracks tailored to meet the rigorous standards of the heavy equipment industry. When choosing a supplier, procurement professionals must consider factors such as manufacturing quality, material sourcing, and after-sales support. The best manufacturers employ advanced technology and rigorous testing to ensure their rubber tracks can withstand the Norwegian landscape's challenges, from frozen terrains to rugged construction sites. As we approach 2025, aligning with reputable manufacturers will be critical for businesses looking to thrive in a competitive market while ensuring operational efficiency and machinery reliability.

Mini Excavator Rubber Tracks to Norwegians Winning in 2025 Manufacturers You Can Rely On

| Manufacturer Location | Track Size (inches) | Type of Rubber | Material Strength (MPa) | Warranty Period (Months) |

|---|---|---|---|---|

| Norway | 12 x 6 | Natural Rubber | 25 | 24 |

| Sweden | 14 x 7 | SBR Rubber | 30 | 36 |

| Finland | 16 x 8 | EPDM Rubber | 32 | 30 |

| Denmark | 18 x 9 | Nitrile Rubber | 35 | 24 |

Related Products