I emphasize superior heat resistance and exceptional anti-abrasion properties for Excavator Rubber Pads. These traits are critical for durability and operational efficiency. I recognize understanding key characteristics ensures optimal performance and longevity.

Key Takeaways

- High temperatures and constant rubbing wear down excavator rubber pads. This makes them break faster.

- Good rubber pads use special materials and designs. These help them last longer and work better.

- Choosing the right pad for your machine and job saves money. It also keeps your equipment working well.

Why Heat Resistance and Anti-Abrasion are Crucial for Excavator Rubber Pads

Impact of Heat on Rubber Pad Degradation

I understand that high temperatures significantly impact the longevity of rubber pads. For high-temperature vulcanized silicone rubber (HTV-SR), heat primarily causes degradation reactions, leading to chain cracking and the production of silanol. When moisture and corona discharge are present, high temperatures can also promote oxidative crosslinking, forming Si-O-Si structures. Increased temperature cycling makes the material harder but more prone to cracking.

Natural rubber also experiences significant changes. Above 40°C, it gradually softens. As temperatures approach 120°C, this softening accelerates, and its strength and hardness decrease. Molecular chains gain more energy, increasing their activity and expanding the distance between molecules. Prolonged exposure to high temperatures accelerates aging, causing molecular chain breakage and cross-linking reactions, which reduces material performance. I observe that high temperatures lead to the aging and deterioration of rubber. Initially, softening may occur, which can be reversible. However, prolonged exposure causes irreversible chemical changes within the rubber polymer, increasing hardness and altering tensile strength and elongation.

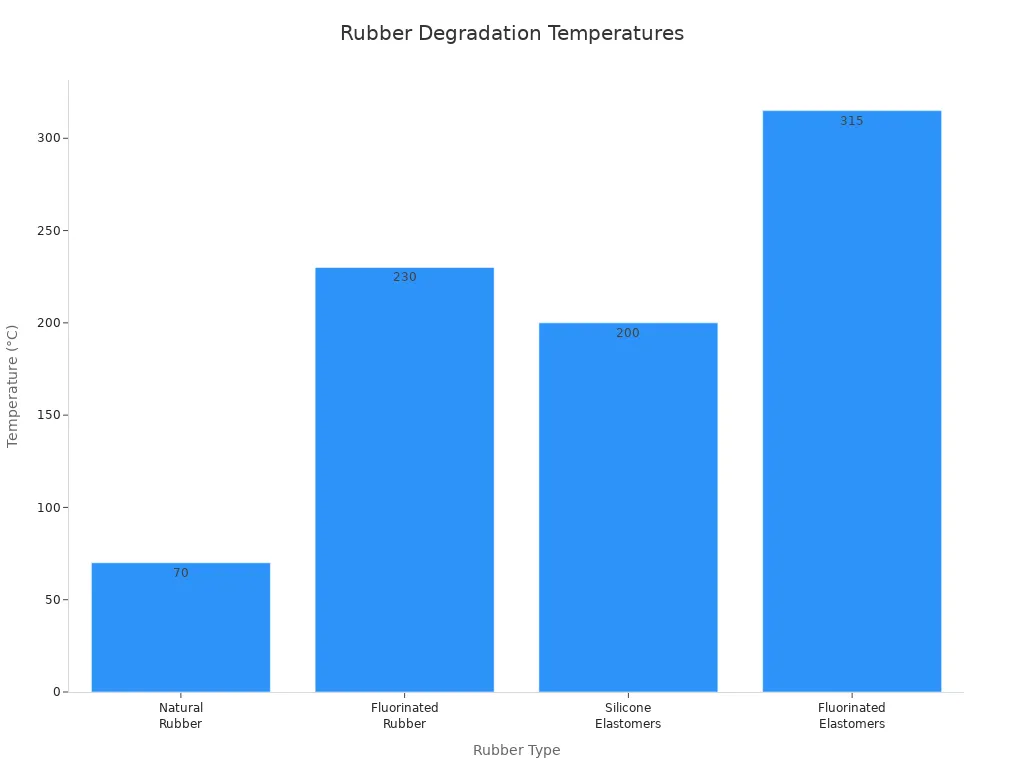

Consider the typical degradation temperatures for various rubber types:

| Rubber Type | Significant Degradation Temperature |

|---|---|

| Natural Rubber | +70°C |

| Fluorinated Rubber | 230°C |

| Silicone Elastomers | Exceeds 200°C |

| Fluorinated Elastomers | Up to 315°C |

The Threat of Abrasion to Pad Lifespan

Abrasion poses a constant threat to the lifespan of Excavator Rubber Pads. I see that abrasive materials like rocks, concrete, and gravel constantly grind against the pads. This constant friction and stress contribute significantly to wear. This mechanism directly reduces the operational life of the pads.

Operational Benefits of High-Performance Pads

High-performance Excavator Rubber Pads offer substantial operational benefits. I find they reduce maintenance costs and equipment damage because high-quality rubber compounds retain protective properties after thousands of hours of operation. They extend equipment life and reduce maintenance requirements through vibration-dampening and floor protection. These pads also reduce soil compaction by approximately 35% and decrease noise pollution levels by 15 decibels. I note they extend equipment lifespan by 20% and potentially reduce unplanned downtime by 38% with smart systems. Proprietary rubber blends can offer a 40-50% longer service life compared to conventional formulations. I also observe reduced operating costs by up to 20% and decreased fuel consumption by 15-30%.

Key Characteristics of Superior Excavator Rubber Pads

Material Composition for Heat Resistance

I know the right material composition is fundamental for heat resistance. I find that specific additives and curing agents significantly enhance thermal stability. For instance, vulcanizing agents like sulfur, peroxides, and metal oxides create a stable three-dimensional network within the rubber. This network improves strength, flexibility, and thermal stability. Sulfur, in particular, boosts heat resistance.

I also rely on antioxidants, such as amines and phenolic compounds. These prevent rubber degradation from oxidation, heat, and UV exposure. They extend the lifespan and maintain performance in high-temperature applications. Accelerators like thiazoles, sulfenamides, and dithiocarbamates optimize the curing process, further improving the rubber compounds’ heat resistance.

I see different vulcanizing systems offer distinct advantages for thermal stability:

| Vulcanizing System | Key Advantages (Thermal Stability) |

|---|---|

| Sulfur Systems | Good properties |

| Peroxide Systems | Heat resistance |

| Metal Oxide Systems | Chemical resistance |

| Resin Systems | Heat resistance |

I also understand how additives provide crucial protection:

| Protection Type | How Additives Help (Thermal Stability) |

|---|---|

| Antioxidants | Interrupt oxidation reactions, especially in heat-exposed applications |

| Heat Stabilizers | Maintain properties at high temperatures, crucial for engine components and industrial equipment |

Temperature Rating Standards and Thermal Stability

I always consider temperature rating standards when selecting rubber pads. These standards indicate the maximum continuous operating temperature a material can withstand without significant degradation. Thermal stability refers to the material’s ability to maintain its physical and chemical properties under varying temperature conditions. I look for pads that exceed the expected operating temperatures of my equipment. This ensures they perform reliably in demanding environments.

Material Hardness and Durometer Readings

I pay close attention to material hardness, often measured by durometer readings. This measurement indicates the rubber’s resistance to indentation. Higher durometer materials are preferred for industrial components like rollers and bushings. They offer superior resistance to abrasion, deformation, and repeated impact. This hardness ensures parts maintain their shape and last longer in demanding environments. It directly contributes to an extended wear life. Conversely, softer rubber, with a lower durometer, excels at conforming to surfaces. This is beneficial for sealing applications, but less ideal for load-bearing components where shape retention under stress is critical. I know an optimized tread pattern is crucial for maintaining excellent grip and ensuring machine stability.

Reinforcement Technologies for Abrasion Resistance

I recognize that internal reinforcement is key to achieving superior abrasion resistance. Excavator rubber track pads incorporate reinforcement elements during their manufacturing process. This integration is crucial for enhancing the structural integrity and load-bearing capacity of the track pads. It leads to superior resistance against wear, tear, and deformation, thereby contributing to their longevity.

I often see several types of internal reinforcement used:

- Steel cords: These are primary reinforcements. They provide high tensile strength, durability, and excellent impact and abrasion resistance. Manufacturers encase them in special insulating rubber to reduce internal friction and enhance adhesion.

- Polyester canvas interlayer: This additional reinforcement is placed between the cords. It increases belt stability.

- Wear-resistant cover: Materials like neoprene form a 4–10 mm thick outer layer. This layer endures material impact and abrasion, showing low wear loss.

- Specialized core rubber: This rubber, with a Shore hardness of 60–70, embeds the wire rope. It creates a cross-linked bond to prevent moisture and debris infiltration, protecting the cords.

I also know that some manufacturers use advanced technologies. For example, Bridgestone MT-Pads utilize multiple internal steel plates. They treat these plates with high-quality bonding agents during the vulcanization process. This ensures maximum structural integrity. These pads also feature a proprietary premium rubber compound. This specialized compound offers superior durability with anti-cut and anti-chunking properties. It significantly outperforms competing brands in wear testing, contributing to an extended service life.

Surface Texture and Tread Patterns

I understand that surface texture and tread patterns are vital for performance. They directly influence traction, ground protection, and wear life. I see many different types of tread patterns available for excavator rubber pads:

- Multi-Bar Rubber Track Tread Pattern

- RD Rubber Track Tread Pattern

- C-Lug Rubber Track Tread Pattern

- EXT Rubber Track Tread Pattern

- Z-Tread Rubber Track Tread Pattern

- CT Rubber Track Tread Pattern

- 51 Lug Rubber Track Tread Pattern

- 56 Lug Rubber Track Tread Pattern

I also categorize them by their design and application:

- Block or Straight-Bar Tread: This features thick rectangular or bar-shaped lugs. It is ideal for general construction and demolition on loose, rocky, or uneven surfaces. It provides optimum traction but can cause surface disruption and more vibration.

- Multi-Bar or Zig-Zag Tread: This has staggered lugs for even weight distribution, a smoother ride, and minimal ground disturbance. It is versatile for mixed or sensitive surfaces like turf and urban areas.

- Turf or Non-Marking Tread: This has a flat or lightly textured surface. It minimizes contact pressure. I use it on sports fields, golf courses, and indoors where surface damage or marks must be avoided.

- Directional or V-Pattern Tread: This features a chevron or V-shaped pattern. It provides self-cleaning in wet or muddy conditions by channeling debris away. I often see it on agricultural machinery, and I know it must be installed correctly.

Other common patterns include:

- C Tread Pattern (aka H tread pattern): This is most common for mini excavators and skid steers. It suits mud, clay, snow, rock, and hard surfaces. It has extra voids for more sidewall grip and moderate self-cleaning.

- V Tread Pattern: I commonly find this on mini excavators for agriculture or light tasks. It provides traction without excessive ground disturbance. It is directional, designed to self-clean by paddling through loose ground.

- Zig zag Tread Pattern (ZZ tracks): This is best for mud and snow removal. It maximizes sidewall length for excellent traction on slippery ground. It has high self-cleaning ability and is directional.

I also consider these options:

- Staggered Block: This offers high versatility with good balance and traction. It minimizes vibration and spreads weight load for increased flotation. It is suitable for asphalt, dirt, grass, and gravel.

- C-Pad (C-Lug, C-Pattern, C-Block): This provides a more aggressive bite than Staggered Block. It offers optimal flotation and traction for hills and slopes. It is effective on asphalt, dirt, grass, and gravel.

- Straight-Bar: This is the most aggressive option. It yields great results in mud and snow and applications where traction is prioritized over ground disturbance. It is suitable for dirt, gravel, mud, and snow.

- Zig Zag: This provides a smooth ride with optimal wear on multiple surfaces. It is also effective in snow and mud. It is suitable for dirt, gravel, mud, and snow.

- Multi-Bar: This is aggressive yet offers a smoother ride than Straight-Bar. It has great flotation and traction. It is suitable for dirt, grass, and snow.

- Turf: This is a turf-friendly pattern. It protects delicate surfaces while maximizing ground contact and providing a smooth ride. It is suitable for asphalt and grass.

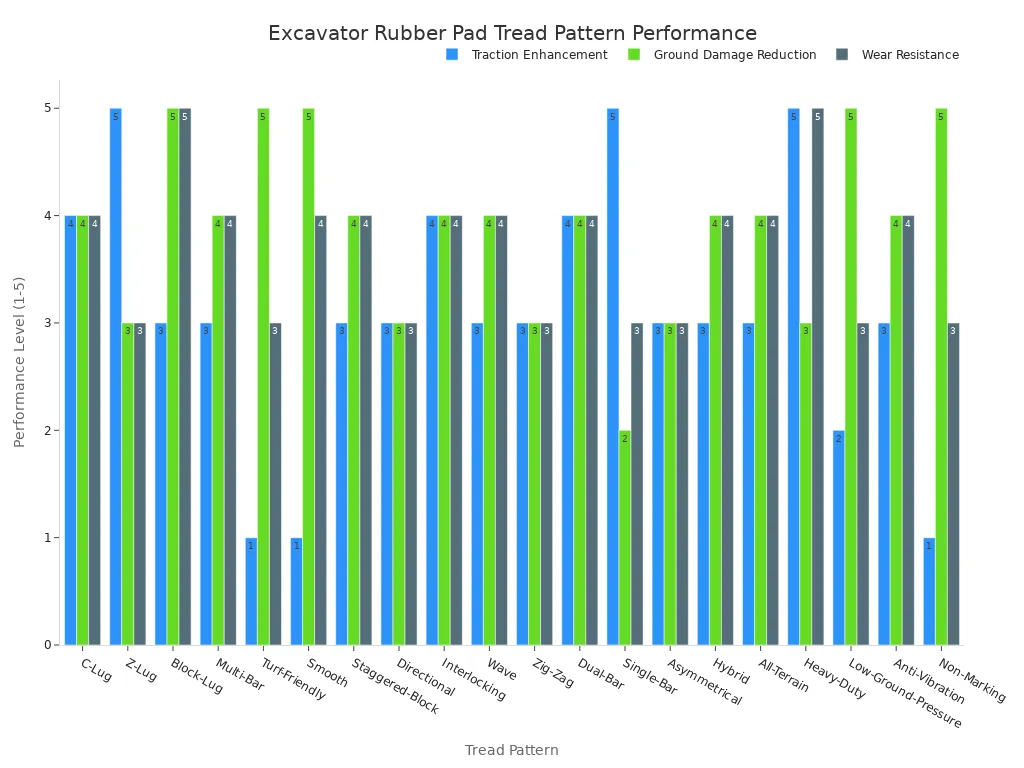

I know each tread pattern offers unique benefits for traction, ground damage reduction, and wear resistance.

| Tread Pattern | Traction Enhancement | Ground Damage Reduction | Wear Resistance | Best Use Cases |

|---|---|---|---|---|

| C-Lug | Excellent traction in dirt, mud, and uneven terrain. | Good, minimizes impact on sensitive surfaces. | High, due to balanced design. | General construction, landscaping, excavation. |

| Z-Lug | Superior traction in challenging conditions like deep mud and snow. | Moderate, can be more aggressive on delicate ground. | Moderate, aggressive pattern can lead to faster wear on hard surfaces. | Extreme conditions, demolition, heavy-duty excavation. |

| Block-Lug | Good all-around traction on various surfaces, including asphalt and concrete. | Excellent, designed to minimize surface disruption. | Very High, large contact area distributes wear evenly. | Road construction, urban landscaping, finished surfaces. |

| Multi-Bar | Enhanced traction on soft ground and slopes. | Good, distributes weight to reduce ground pressure. | High, durable for varied terrain. | Agricultural applications, soft soil conditions, hilly areas. |

| Turf-Friendly | Minimal traction, designed for delicate surfaces. | Excellent, specifically engineered to prevent damage. | Moderate, softer compound for surface protection. | Golf courses, parks, residential landscaping. |

| Smooth | Very low traction, primarily for indoor or very smooth surfaces. | Excellent, leaves no marks or damage. | High, even wear on smooth surfaces. | Indoor demolition, warehouse work, cleanroom environments. |

| Staggered-Block | Improved traction and stability on uneven terrain. | Good, balances grip with surface protection. | High, versatile for mixed use. | Mixed terrain, general construction, utility work. |

| Directional | Optimized traction for specific forward or backward movement. | Varies, depending on specific design and application. | Varies, can be high if used as intended. | Specialized machinery, specific directional tasks. |

| Interlocking | Enhanced grip and reduced vibration. | Good, stable contact patch. | High, even load distribution. | Paving, road milling, stable platform needs. |

| Wave | Good traction and smooth ride. | Good, gentle on surfaces. | High, even wear. | General construction, landscaping, utility work. |

| Zig-Zag | Improved traction in loose materials. | Moderate, can be more aggressive. | Moderate, depending on material. | Loose soil, gravel, sand. |

| Dual-Bar | Enhanced traction and stability. | Good, balanced pressure. | High, durable for varied use. | General construction, excavation, utility work. |

| Single-Bar | Aggressive traction in soft conditions. | Moderate to high, can be damaging on hard surfaces. | Moderate, aggressive pattern can wear faster. | Mud, extreme off-road, specialized excavation. |

| Asymmetrical | Optimized for specific machine movements or terrain. | Varies, designed for specific interaction. | Varies, depending on application. | Specialized tasks, unique terrain challenges. |

| Hybrid | Combines features for versatile performance. | Good, balances different tread benefits. | High, designed for adaptability. | Mixed terrain, varied job sites, general purpose. |

| All-Terrain | Versatile traction across various surfaces. | Good, designed for adaptability. | High, durable for diverse conditions. | General construction, landscaping, utility work. |

| Heavy-Duty | Maximum traction and durability for extreme conditions. | Moderate to high, can be aggressive. | Very High, built for endurance. | Demolition, quarry work, heavy excavation. |

| Low-Ground-Pressure | Designed to minimize impact on sensitive surfaces. | Excellent, wide footprint distributes weight. | Moderate, softer compounds for surface protection. | Environmentally sensitive areas, golf courses, parks. |

| Anti-Vibration | Reduces machine vibration for operator comfort and machine longevity. | Good, stable contact. | High, even wear. | Long operating hours, precision work. |

| Non-Marking | Leaves no marks on finished surfaces. | Excellent, specialized rubber compound. | Moderate, softer compound for non-marking properties. | Indoor work, finished flooring, clean environments. |

Evaluating Quality and Making the Right Choice for Excavator Rubber Pads

Adhesion Strength and Rubber-to-Metal Bonding

I know strong adhesion between rubber and metal is crucial for pad durability. I always look for pads with superior bonding. Manufacturers test this bond strength by pulling or peeling bonded specimens. They perform visual inspections to check for 100% rubber tear, which indicates a strong bond. Tensile bond testing involves pulling a rubber sample sandwiched between two metal pieces until it breaks. ASTM D429, ASTM D903, and ISO 813 are common standards for measuring adhesion. ASTM D2228 also measures adhesive strength. This standard uses methods like Method A for static strength, Method B for 90-degree peel tests, and Method G for double shear cylindrical samples. These tests ensure the rubber stays firmly attached to its metal backing.

Fit, Compatibility, and Installation Mechanisms

I understand proper fit and compatibility are essential for performance. I consider the installation mechanism carefully. Common options include clip-on, bolt-on, and chain-on systems. Clip-on pads attach quickly to existing steel tracks. Bolt-on pads secure with bolts to the track shoe, offering a durable solution. Chain-on pads integrate directly into the track chain, providing a robust option for heavy-duty applications. GeoGrip pads, for example, fit directly onto link chains. MT-Pads are clip-on pads that fit over existing steel shoes. MST also provides both bolt-on and clip-on technologies. I choose the mechanism that best suits my machine and operational needs.

Manufacturer Reputation and Warranty

I always prioritize manufacturers with a strong reputation for quality. A reputable manufacturer stands behind their products. I also check the warranty. For instance, DEKK offers a 12-month warranty for their rubber pads. A good warranty provides peace of mind and shows the manufacturer’s confidence in their product’s longevity.

Assessing Operating Environment and Material Specifications

I assess my operating environment to choose the right material specifications. For abrasive environments, I look for advanced anti-cut and anti-chunking formulations. Polyurethane track pads are also a suitable material for these tough conditions. Premium rubber compounds offer maximum wear resistance.

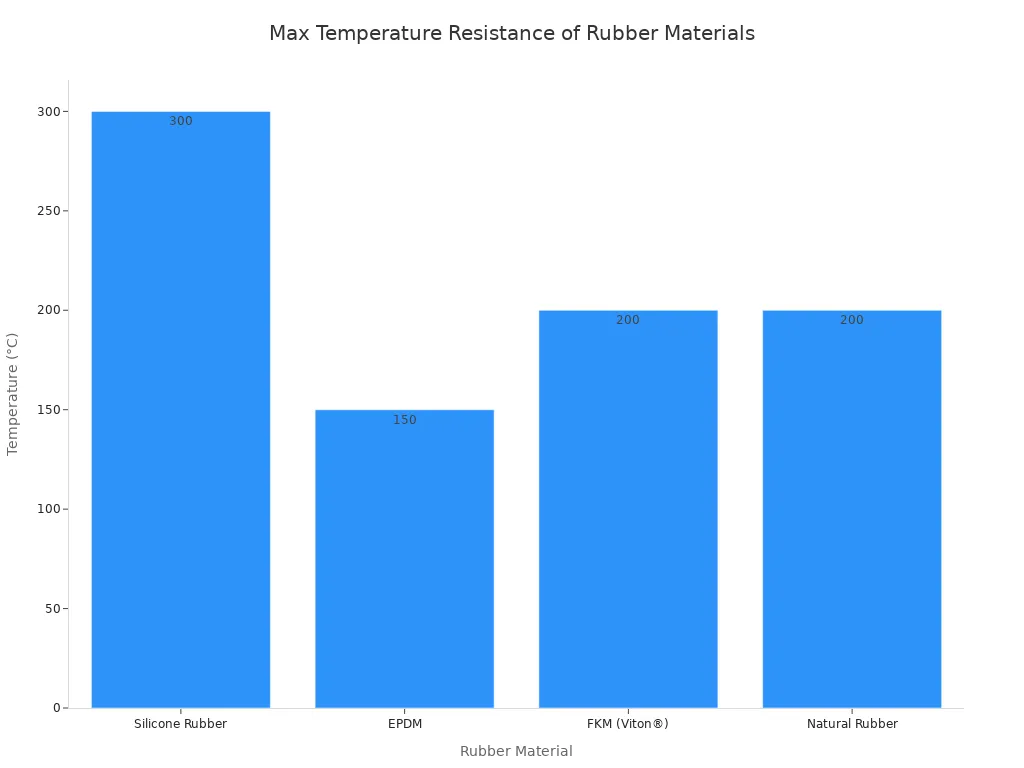

I also consider temperature extremes.

| Rubber Material | Maximum Temperature Resistance |

|---|---|

| Silicone Rubber | Up to 300°C |

| EPDM | Up to 150°C |

| FKM (Viton®) | Up to 200°C |

| Natural Rubber | ~200°C (softens) |

|

|

| I ensure the chosen material’s temperature resistance aligns with my operating conditions. For example, EPDM handles -29°C to 177°C, while Silicone can go from -100°C to 250°C. Premium Excavator Rubber Pads are engineered to perform well in a wide range of weather, from freezing cold to intense heat. |

Considering Long-Term Value

I always consider the long-term value of my investment. Premium-grade rubber tracks offer a better return on investment compared to standard options. Their benefits include a longer service life, better protection for surfaces, and lower operating costs. While upfront costs for high-quality pads might be higher, they offer superior durability and performance. This reduces labor costs and the frequency of replacement.

I conclude that selecting Excavator Rubber Pads with proven heat resistance and anti-abrasion properties is essential for any project. I always match material composition, design, and manufacturer specifications precisely to my operational demands. This careful consideration ensures optimal performance, extended longevity, and significant cost-effectiveness for my equipment.

FAQ

What makes rubber pads degrade from heat?

I find high temperatures cause rubber to soften, then harden and crack. This leads to molecular chain breakage and cross-linking, which reduces performance.

How do I choose pads for abrasive conditions?

I recommend pads with advanced anti-cut and anti-chunking formulations. Polyurethane or premium rubber compounds offer maximum wear resistance in tough environments.

Why are tread patterns important for excavator pads?

I know tread patterns are vital for traction, ground protection, and wear life. They ensure machine stability and minimize surface damage.

Post time: Dec-15-2025