Construction sites in 2025 look busier than ever. Machines roar, and workers rely on ASV Loader Tracks for tough jobs. The global market for these tracks hits $3.6 billion in 2025. Check out these numbers:

| Metric | Insight |

|---|---|

| Global Market Size (2025) | USD 3.6 billion |

| U.S. Construction Spending | USD 2.17 trillion |

| Key Regional Growth | U.S., China, India |

Key Takeaways

- ASV Loader Tracks deliver superior traction and stability on all terrains, reducing operator fatigue and extending the work season by 12 days.

- Their advanced rubber construction and Posi-Track system increase track life by 140%, cut maintenance needs, and lower repair costs significantly.

- Innovations in 2025 improve ride comfort, safety, and machine adaptability, helping operators work longer, save money, and finish jobs faster.

ASV Loader Tracks: Performance, Durability, and Ground Protection

Superior Traction on All Terrains

Mud, snow, gravel, or steep hills—ASV Loader Tracks handle them all like a champ. Operators love the way these tracks grip the ground, even when the weather turns wild. The secret? Advanced tread designs and a fully suspended frame. These features keep the machine steady and the operator in control, no matter how slippery or uneven the surface gets. The rubber-on-rubber contact points hug the terrain, while high-strength polyester wires run through the tracks, stopping stretching and derailment in their tracks.

Operators report less fatigue after long days, thanks to reduced vibrations and shocks. The all-season tread means work never stops, even when the weather tries to play tricks.

Here’s how ASV Loader Tracks stack up against traditional tracks:

| Performance Metric | Traditional Loader Tracks | ASV Loader Tracks |

|---|---|---|

| Traction and Stability | Lower grip on mud, snow, gravel; less stable on uneven terrain | Superior grip and stability across mud, snow, gravel, and steep inclines |

| Track Life | 500-800 hours | Approximately 1,200 hours (140% increase) |

| Fuel Consumption | Baseline | 8% reduction due to better weight distribution |

| Workable Season Extension | Not applicable | 12 days longer operational season |

| Maintenance Frequency | 2-3 replacements per year | Once yearly replacement, 85% fewer emergency repairs |

| Operator Fatigue | Higher due to vibrations and jolts | Reduced due to fully suspended frame and vibration absorption |

Advanced Rubber Construction and Longevity

ASV Tracks use a mix of high-quality synthetic and natural rubber. Additives like carbon black and silica make the tracks tough against cuts and cracks. Synthetic fibers such as SBR keep the tracks flexible, even when the temperature drops or soars. Reinforced polyester cords run through the tracks, giving them the muscle to handle heavy loads and rough terrain.

Operators see the difference. Tracks last longer—sometimes up to 5,000 hours with good care. The Posi-Track system absorbs shocks and vibrations, so the tracks don’t wear out as fast. Machines keep rolling, and downtime drops.

Note: Proper maintenance, like daily tension checks and cleaning, helps these tracks reach their full lifespan.

Even Weight Distribution and Minimal Ground Pressure

ASV Loader Tracks spread the machine’s weight over many contact points. This design lowers ground pressure to as little as 3.1 psi. The result? Machines can work on soft or sensitive ground without tearing up the turf. After a rainstorm, operators get back to work sooner because the tracks don’t sink or leave deep ruts.

Industry reviews praise the wide tracks and even weight distribution. The patented undercarriage design almost eliminates derailment and gives the operator a smoother ride. The RT-65 model, for example, achieves ground pressure as low as 4.2 psi, making it perfect for wetlands or landscaped areas.

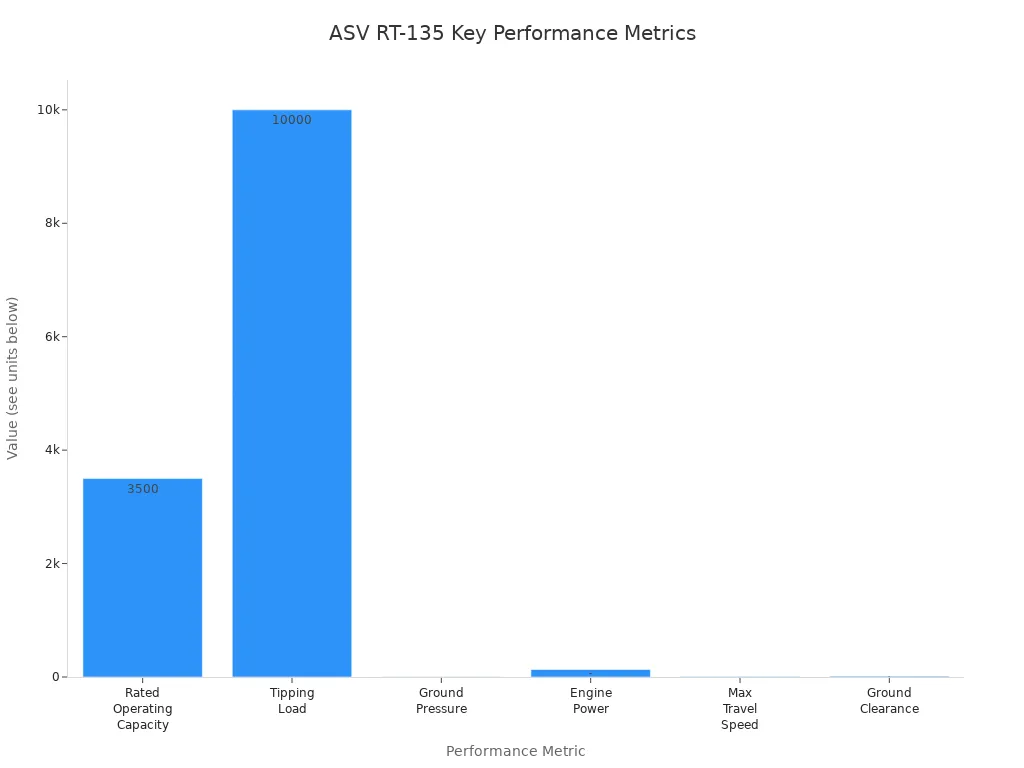

| Metric | ASV RT-135 Specification |

|---|---|

| Rated Operating Capacity | 3,500 lbs at 35% load |

| Tipping Load | 10,000 lbs |

| Ground Pressure | 4.7 psi |

| Engine Power | 132 hp (turbocharged Cummins 3.8L diesel) |

| Max Travel Speed | 10 mph |

| Ground Clearance | 15 inches |

| Track Suspension | Posi-Track® rubber-track with suspended wheels and axles |

| Operator Comfort | MAX-Series cab with spacious interior and upgraded HVAC |

Reduced Maintenance and Cost Efficiency

Nobody likes surprise repairs. ASV Loader Tracks help keep those to a minimum. The advanced rubber compounds and reinforced construction mean fewer replacements and less downtime. Operators report only one replacement per year, compared to two or three with traditional tracks. Emergency repairs drop by 85%.

Maintenance is simple. The tracks are easy to clean, and the pre-stretched design means fewer tension adjustments. The Posi-Track undercarriage keeps debris out, so performance stays high. Owners save money on repairs and replacements, and machines spend more time working.

Tip: Regular inspections and cleaning routines help maximize track life and keep costs down.

ASV Loader Tracks: Operator Comfort, Versatility, and 2025 Innovations

Enhanced Ride Quality and Reduced Vibration

Operators spend long hours in their machines, so comfort matters. ASV Loader Tracks turn bumpy rides into smooth adventures. The rubber track undercarriage acts like a shock absorber, soaking up jolts from rocks and ruts. The MAX-Series cab feels like a cozy cockpit, with extra space and controls that fit right in your hand. Operators enjoy cool air from the HVAC system, even on the hottest days. The joystick controls make every move feel easy, and the all-weather pressurized cab keeps out dust and rain. The Posi-Track dual-level suspension glides over rough ground, so operators finish the day with less fatigue and more energy.

- The ASV rubber track undercarriage gives a smoother ride.

- The MAX-Series cab offers more space and ergonomic controls.

- The HVAC system keeps the air fresh and comfortable.

- Joystick controls reduce strain and make operation simple.

- The pressurized cab protects from weather and dust.

- The Posi-Track suspension reduces vibration and operator fatigue.

Operators say, “It feels like riding on air, not rocks!”

Safety and Stability on Challenging Sites

Construction sites throw curveballs—mud, ice, steep slopes, and falling debris. ASV Loader Tracks handle these challenges with confidence. The four-season tracks grip snow and ice, letting work continue when wheeled machines slip and slide. The tracks’ flexibility and low ground pressure keep the loader steady, even on soft or uneven ground. Operators stay safe by moving slowly and carrying loads low, especially on tricky surfaces.

The RT-135 Forestry loader brings extra muscle to the job. Its all-terrain rubber-tracked undercarriage powers through dense woods and rough hills. Safety features like ROPS and FOPS protect operators from rollovers and falling objects. The suspended undercarriage lets each track move independently, hugging the ground for better traction and stability. This design means higher tipping capacity and safer operation on slopes.

Adaptability to Multiple Machines and Job Requirements

ASV Loader Tracks love a challenge. They fit machines big and small, from compact loaders to heavy-duty beasts. Landscapers, farmers, builders, and even the military trust these tracks to get the job done. The Posi-Track system turns one loader into a multi-tool hero. Attach a mower, brush cutter, auger, or snow plow—these tracks handle it all.

- The Posi-Track undercarriage works across construction, utility, landscaping, agriculture, and military jobs.

- One machine can switch between tools like mowers, augers, and plows.

- ASV Loader Tracks offer better mobility than rubber tires and better traction than steel tracks.

- The partnership with Caterpillar led to Multi-Terrain Loaders using ASV’s technology.

- Compact loaders with ASV tracks squeeze into tight spaces and travel easily on trailers.

- These machines tackle stump removal, trenching, snow clearing, and more.

- The tracks protect lawns and soft ground, leaving less mess behind.

Operators share stories of finishing jobs after rain, working on hills, and saving time on repairs. Landscapers see fewer ruts in lawns. Farmers notice healthier fields. Builders keep projects moving, rain or shine.

- The Posi-Track system spreads weight for better traction on gravel, mud, and grass.

- Hydraulic systems power attachments for digging, grading, and trenching.

- High lifting capacity and stability make tough lifts safer.

- Cooling systems keep machines running strong, even on long days.

- Optional air ride seats help operators work longer with less fatigue.

Technological Advancements for 2025

The year 2025 brings a wave of smart upgrades to ASV Loader Tracks. The RT-65 compact track loader leads the charge with a new Yanmar Tier 4 Final diesel engine, advanced hydraulics, and electronic controls. The Posi-Track undercarriage now uses two independent torsion axles per side, making rides smoother and traction stronger. Ground pressure drops as low as 4.2 psi, so machines float over soft ground without leaving a mark.

Operators get a boost from Auto 2-speed, speed-sensitive ride control, and self-leveling loader arms. The work-tool positioner and return-to-position tech save time on repetitive tasks. Inside the cab, a 7-inch color display, backup camera, and roof escape hatch add comfort and safety. The optional Yanmar SmartAssist telematics system tracks machine health, sends alerts, and helps prevent theft. Service is easier than ever, with top-notch engine access and a no-derailment guarantee.

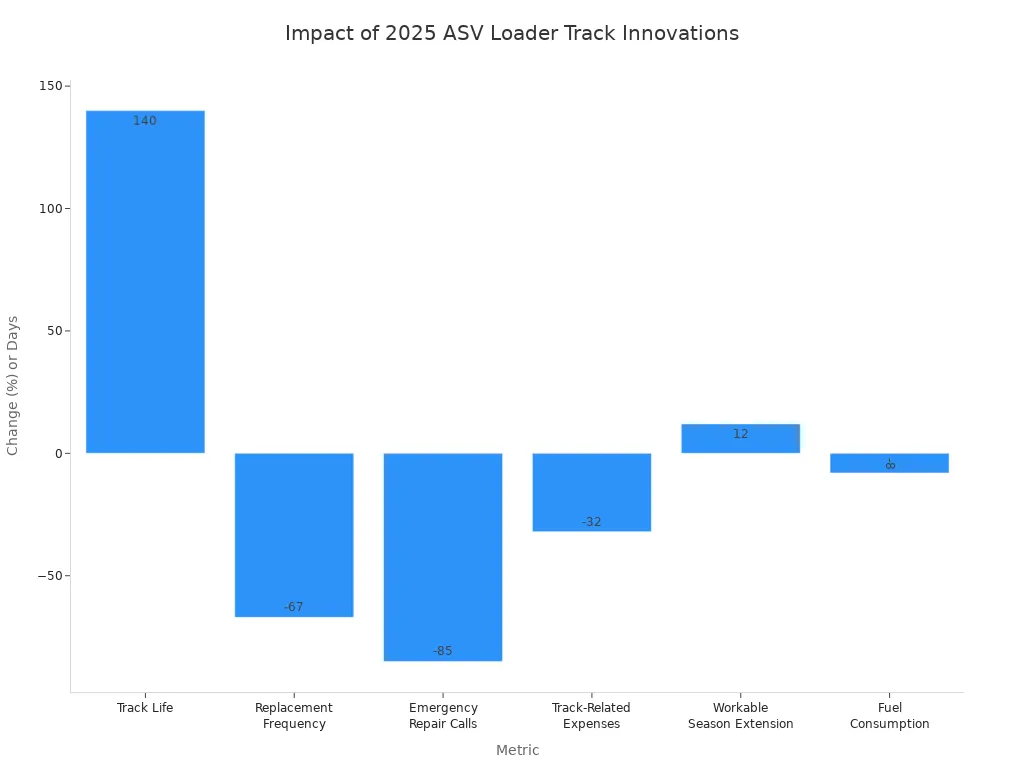

Here’s how these innovations make a difference:

| Feature/Metric | Benefit/Impact |

|---|---|

| Posi-Track System | Even weight, less ground pressure, no sinking, smooth ride on tough terrain |

| Rubber-on-Rubber Contact | Less wear and vibration, more comfort, longer work hours |

| High-Strength Polyester Wires | 140% more durable, fewer replacements, lower costs |

| Track Life | Up 140% (from 500 to 1,200 hours) |

| Replacement Frequency | Down 50-67% (from 2-3 times/year to 1 time/year) |

| Emergency Repair Calls | Down 85% |

| Total Track-Related Expenses | Down 32% |

| Workable Season Extension | Up 12 days |

| Fuel Consumption Reduction | Down 8% |

The Posi-Track system keeps machines steady and safe, even with heavy loads. Rubber-on-rubber contact means less vibration and more comfort. High-strength polyester wires make the tracks last longer and cut down on repairs. Operators work longer, save money, and finish more jobs in every season.

ASV Loader Tracks steal the show on every job site. Industry experts agree:

- Compact track loaders tackle tough terrain and keep ground smooth.

- ASV’s undercarriage lets machines climb slippery slopes with ease.

- Operator comfort boosts productivity and keeps spirits high.

Smart builders choose these tracks for a winning edge.

FAQ

How long do ASV Loader Tracks usually last?

Operators often see these tracks outlast the competition. With good care, they can roll for up to 5,000 hours. That’s a lot of muddy adventures!

Can ASV Loader Tracks handle snow and ice?

Absolutely! These tracks grip snow and ice like a polar bear’s paws. Operators keep working while others slip and slide. ❄️

Are ASV Loader Tracks easy to maintain?

Yes! Owners find cleaning and tension checks simple. The design keeps debris out. Less time fixing, more time digging. Everyone wins!

Post time: Aug-01-2025