Selecting the right Rubber Track boosts loader performance. Contractors see faster grading and fewer emergency repairs.

- Productivity rises by up to 25% with correct track width.

- Track life can improve by 40%, cutting downtime.

Premium tracks last longer and reduce unexpected breakdowns.

Key Takeaways

- Choosing the right rubber track boosts loader performance by improving traction, stability, and ride comfort, helping operators work faster and safer on different terrains.

- Matching track size, tread pattern, and material to your worksite conditions protects the ground, reduces wear, and ensures better control for tasks like construction, landscaping, or working on hard surfaces.

- Regular inspection, cleaning, and proper tension keep rubber tracks in top shape, prevent breakdowns, and extend their lifespan, saving time and repair costs.

Rubber Track Selection and Loader Performance

Traction and Stability Benefits

Rubber Track selection plays a key role in loader traction and stability. The right track reduces ground pressure, which helps loaders move across soft soil without sinking. Operators notice better control and fewer stuck incidents, especially on slopes or rough terrain. Machines with well-chosen tracks maintain stability and grip on mud, turf, snow, and rocks. Improved traction leads to faster job completion and safer operation.

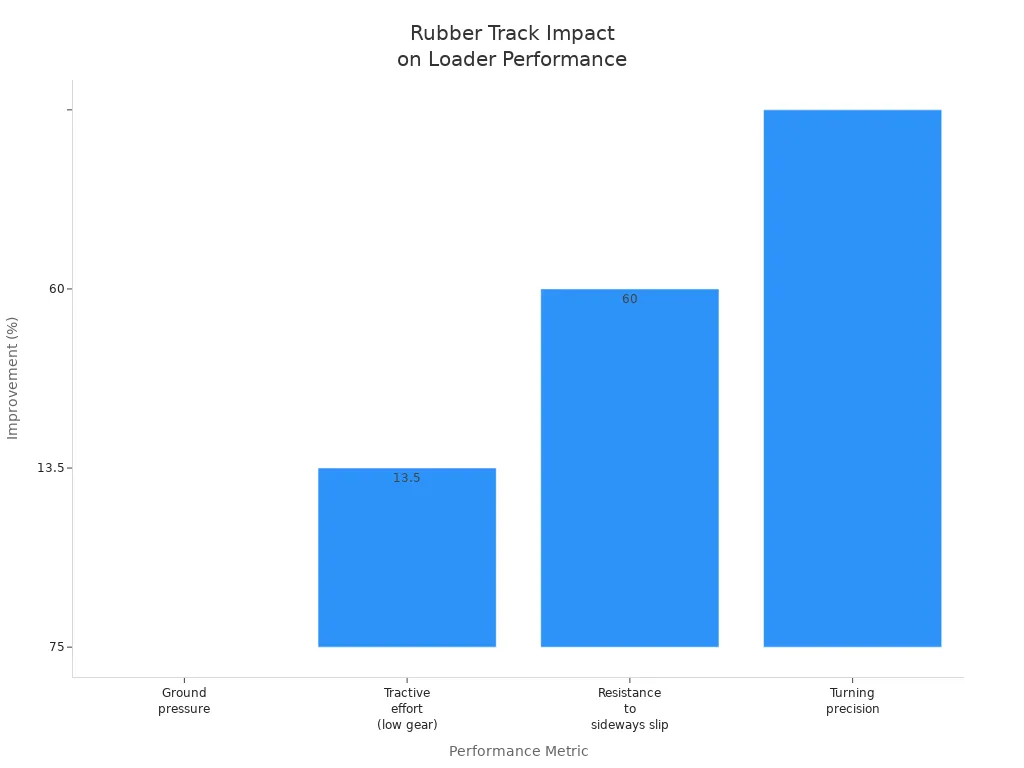

| Performance Metric | Improvement | Explanation |

|---|---|---|

| Ground pressure | Up to 75% reduction | Reduces soil compaction and prevents sinking |

| Tractive effort (low gear) | +13.5% | Increases pushing power and traction |

| Resistance to sideways slip | Up to 60% | Enhances control and reduces slipping |

| Turning precision | Improved | Allows better maneuverability on soft ground |

Rubber tracks use advanced tread patterns and multi-layered compounds reinforced with steel. Serrated or self-cleaning tread designs improve grip on slippery surfaces and protect delicate ground. These features help loaders perform well in many environments.

Tip: Operators can choose tread patterns that match their worksite needs. Multi-bar and zigzag designs offer strong traction on soft ground, while block patterns work well for heavy-duty tasks.

Ride Comfort and Vibration Reduction

Rubber Track design affects ride comfort and vibration levels. Tracks with multi-bar tread designs lower vibration and provide a smoother ride. Operators experience less fatigue and enjoy quieter operation. The flexibility of rubber tracks absorbs shocks from uneven surfaces, making long workdays more comfortable.

- Rubber tracks generally improve operator comfort compared to steel tracks by reducing vibration and noise.

- Multi-bar tread is favored for providing one of the smoothest rides and is suitable for mixed terrain.

- Zigzag tracks offer good traction on ice and mud but may not be as smooth on hard surfaces.

- Block tracks are durable but provide a rougher ride, best for heavy-duty jobs.

Bridgestone’s Vortech rubber tracks feature an optimized internal structure that reduces bending resistance during rotation. This design leads to smoother driving and less operator fatigue. Tests show a 26% improvement in driving efficiency with these enhancements.

Note: Choosing the right tread pattern can balance traction and comfort. Operators often prefer multi-bar tracks for their smooth ride and reduced fatigue.

Durability and Wear Resistance

Durability and wear resistance depend on the quality of the rubber track materials and construction. High-grade rubber compounds, such as EPDM and SBR, offer excellent resistance to wear, weather, and temperature changes. Tracks reinforced with steel cords or Kevlar last longer and resist cuts, punctures, and corrosion.

| Framework Type | Wear Resistance Properties | Additional Characteristics |

|---|---|---|

| Steel Wire Framework | High strength and excellent wear resistance | Heavyweight, high tensile strength, suitable for heavy-duty machinery |

| Kevlar Framework | High strength and excellent wear resistance | Lightweight, corrosion-resistant, long lifespan, good vibration absorption |

Rubber tracks used on loaders typically last between 400 and 2,000 operating hours under heavy-duty conditions. Lifespan depends on terrain, operator skill, and maintenance. Tracks last longer on soft soils and wear faster on rocky or abrasive surfaces. Regular inspections, cleaning, and tension adjustments help extend track life.

Tip: Operators should inspect tracks every 50 hours and clean them after use in harsh environments. Proper maintenance ensures longer service life and fewer breakdowns.

Key Rubber Track Features to Consider

Material Quality and Compounds

Material quality plays a major role in how long a Rubber Track lasts and how well it performs. High-grade rubber compounds resist cuts, tears, and harsh weather. Synthetic rubbers like EPDM and SBR work well in tough construction environments. Natural rubber blends give flexibility and strength, which helps on soft ground. Reinforcements such as steel cords or textile wrapping add strength and keep the track from stretching. Some tracks use extra layers or special materials for even more durability.

| Component | Material Property / Function |

|---|---|

| Rubber | Quality affects durability and puncture resistance |

| Metal pieces | Reinforce carcass and engage sprocket for drive |

| Steel cord | Provides tensile strength and rigidity |

| Textile wrapping | Ensures consistent steel cord alignment |

Premium tracks use better materials and last longer than standard tracks. They handle heavy loads and rough terrain with less wear.

Tread Pattern Options

Tread pattern affects how a loader moves on different surfaces. Smooth tread works best on grass or fragile ground because it lowers ground pressure. Multi-bar and straight bar patterns give strong traction in mud or wet areas. Zigzag and C-lug patterns help loaders grip on muddy or snowy slopes. Each pattern has its own strengths.

| Tread Pattern | Best Use | Key Features |

|---|---|---|

| Smooth | Grass, fragile surfaces | Low ground pressure, gentle on turf |

| Multi-bar/Straight | Mud, wet conditions | Aggressive traction, prevents mud buildup |

| Zigzag (Z-Lug) | Mud, snow, mixed terrain | Excellent self-cleaning, strong side grip |

| C-Lug | Clay, muddy, mixed conditions | Notched blocks, good handling, stable ride |

Tip: Operators should match tread pattern to the main jobsite surface for best results.

Track Size, Width, and Fit

Track size and width affect loader stability and movement. Wide tracks spread weight over a bigger area, which keeps the loader from sinking on soft ground. Narrow tracks help loaders turn better in tight spaces but may sink on soft soil. The right fit keeps the track from slipping or coming off. Poor fit or tension can cause early wear, slippage, or even accidents. Regular checks and proper tension help loaders work safely and efficiently.

- Wide tracks: Better stability, less ground pressure, ideal for soft or muddy ground.

- Narrow tracks: Better maneuverability, tighter turns, best for hard or tight spaces.

- Proper fit: Prevents slippage, reduces wear, and keeps the loader safe.

Note: Always check track tension and fit before starting work to avoid problems and keep the loader running smoothly.

Matching Rubber Track to Application and Terrain

Construction and Demolition Sites

Construction and demolition sites demand tracks that handle rough ground, debris, and frequent changes in surface. Operators often choose multi-bar, padded, or reinforced rubber tracks for these jobs. These tracks provide strong traction, resist wear, and reduce vibration. The table below shows how each type meets the needs of these sites:

| Rubber Track Type | Key Features | Best Use Case |

|---|---|---|

| Multi-Bar | High traction, steel core, wear resistance | Mixed surfaces, gravel, dirt, pavement |

| Padded | Extra rubber padding, vibration reduction | Urban construction, operator comfort |

| Reinforced | Steel cords, extra layers, high durability | Excavation, demolition, heavy-duty work |

Operators should clean the undercarriage often to extend track life in these tough environments.

Landscaping and Soft Ground

Landscaping and soft ground work require tracks that protect turf and prevent sinking. Wider tracks spread the loader’s weight, reducing ground pressure and keeping the machine from damaging grass or soil. Tread patterns like turf-friendly hex or block designs help loaders float over soft areas. Operators select tracks with flexible rubber compounds and reinforced sidewalls for extra strength when working near roots or stumps.

- Wide tracks minimize ground disturbance.

- Turf-friendly tread patterns protect delicate surfaces.

- Reinforced tracks handle roots and uneven ground.

Hard Surfaces and Pavement

Loaders on hard surfaces and pavement need tracks that last long and run smoothly. Multi-bar or block tread patterns work well because they reduce vibration and wear slowly. Tracks made from high-grade synthetic rubber, with steel cords inside, resist cuts and heat from friction. Proper sizing ensures the track fits well and performs safely.

Choosing the right tread pattern for pavement helps loaders move quietly and protects the surface.

Wet, Muddy, and Rocky Conditions

Wet, muddy, and rocky areas challenge both the loader and its tracks. Specialized tread patterns, like zigzag or chevron, improve grip and help mud fall away from the track. Tracks for these conditions use strong rubber blends and steel reinforcements to prevent stretching and damage. The table below compares track types for these tough terrains:

| Track Type | Terrain Suitability | Key Features |

|---|---|---|

| Zigzag (Chevron) | Wet, muddy, slippery slopes | Self-cleaning, strong traction |

| Multi-bar Lug | Soft, loose surfaces | High traction, may clog with mud |

| Block | Heavy-duty, rocky areas | Durable, less traction |

| H-Pattern | Mixed terrain | Reduces vibration, protects parts |

Tracks with self-cleaning treads keep loaders moving in mud and snow.

Rubber Track Maintenance for Peak Performance

Inspection and Wear Signs

Regular inspection helps loaders perform safely and efficiently. Operators should follow these steps to spot early signs of wear:

- Check tracks daily for cuts, cracks, and exposed wires.

- Inspect tread depth. Shallow treads mean the track needs replacement soon.

- Adjust track tension as recommended by the equipment manual.

- Remove debris like rocks or mud from the undercarriage.

- Examine rollers, idlers, and sprockets for proper alignment and wear.

- Watch for gaps between the sprocket and track. Large gaps signal wear.

Tip: Daily inspections prevent sudden breakdowns and keep the loader ready for work.

A table below shows how often to inspect different parts:

| Component | Inspection Frequency |

|---|---|

| Track tension & damage | Daily |

| Sprocket rollers | Every 50 hours |

| Full undercarriage check | Monthly |

Cleaning and Storage Tips

Keeping tracks clean and storing them well extends their life. Operators should:

- Clean tracks after each shift using a stiff brush or low-pressure water.

- Avoid high-pressure washers, which can force grit into seals.

- Focus on the undercarriage, where debris collects.

- Store tracks in a dry, covered place away from sunlight and extreme temperatures.

- Check stored tracks for cracks or other damage.

Note: Proper cleaning and storage help prevent rubber cracking and keep tracks flexible.

Replacement Timing and Lifespan

Loader tracks usually last between 400 and 2,000 hours. Several factors affect this range, such as operator skill, ground type, and maintenance habits. Signs that a track needs replacement include:

- Cracks or deep cuts in the rubber.

- Exposed steel cords.

- Sprockets slipping or making unusual noises.

- Tracks that cannot hold tension.

Operators should measure tread depth and check for abnormal noises during use. Using the correct size and following a regular maintenance schedule helps maximize the lifespan of each Rubber Track.

Selecting the right track and maintaining it properly leads to better loader performance and longer service life.

- Tracks with reinforced construction and high-grade compounds resist wear and damage, supporting loader efficiency.

- Regular cleaning, inspections, and correct tension reduce downtime and repair costs.

- Operators report higher productivity and lower expenses with quality tracks.

FAQ

How often should operators inspect rubber tracks?

Operators should check rubber tracks daily. They look for cuts, cracks, and loose tension. Regular checks help prevent sudden breakdowns.

Tip: Early inspections save time and money.

What is the best way to clean rubber tracks?

Operators use a stiff brush or low-pressure water. They remove dirt and debris after each shift. Clean tracks last longer and work better.

Can rubber tracks be used in cold weather?

Yes, rubber tracks work in temperatures as low as -25°C. Operators should avoid sharp turns on icy surfaces to prevent damage.

| Temperature Range | Track Performance |

|---|---|

| -25°C to +55°C | Reliable and flexible |

Post time: Aug-27-2025