I often think about what truly makes heavy equipment perform. For me, ASV tracks are a clear standout. They give machines incredible traction and flotation, which is their core advantage. The Posi-Track system, a unique design, really changed the game for compact track loaders.

Key Takeaways

- ASV tracks use a special Posi-Track system. This system helps machines move smoothly over rough ground. It also prevents them from getting stuck.

- ASV tracks are very strong. They use special rubber and tough materials. This makes them last longer than other tracks.

- ASV machines work well in tough places. They give good grip and float over soft ground. This helps them save fuel and makes the ride smooth.

The Innovative Engineering of ASV Tracks

When I look at ASV machines, I see a lot of smart thinking. The engineering behind ASV tracks is truly impressive. It is not just about putting rubber on the ground. It is about a whole system designed for top performance.

Patented Posi-Track Undercarriage

I think the Posi-Track undercarriage is where ASV really shines. It is not just an add-on; engineers designed it from the start to run on tracks. This makes a huge difference. For example, it has independent suspension. This comes from two torsion axles in each undercarriage. Some models even have suspended roller wheels. This design helps the machine move smoothly over rough ground.

The undercarriage also has many wheel contact points. It uses guide lug surfaces on the flexible track. This prevents derailment, especially when I am working on slopes. I notice the superior weight balance too. This helps a lot with slope performance. The many contact points and wide tracks give these machines industry-leading low ground pressures. Plus, I get superior ground clearance. This means I can go over obstacles without getting stuck. The drive motors send power to patented internal-drive sprockets. Internal rollers also reduce friction loss. This design maximizes power to attachments. It uses large line sizes, hydraulic coolers, and direct-drive pumps.

Advanced Rubber Track Composition

I am always curious about what makes these tracks so tough. ASV tracks use some really advanced materials. They craft them with special rubber compounds and reinforced materials. I learned they use natural rubber, which is great for flexibility. They also include quality steel for strength. What really surprised me is the use of Aramid string. This material is super tough, like what they use in bulletproof vests! Polyester string also adds to the track’s durability.

This careful mix of materials means these tracks last a long time. I have seen that ASV’s rubber tracks can offer up to 1,000 hours of extra service life. This is compared to traditional steel-embedded tracks. That is a lot of extra work time!

| Track Type | Service Life (Hours) |

|---|---|

| ASV Rubber Tracks | 1,000 – 1,500+ |

| Standard Tracks/Tires | 500 – 800 |

Optimized Undercarriage Design

The way ASV designs its undercarriage really helps with stability. I feel much more in control when I operate these machines. The patented system keeps the track firmly on the ground. This greatly minimizes any risk of derailment. Specialized roller wheels spread the machine’s weight evenly. This keeps the ground pressure consistent. The weight distribution is also optimized. This means the weight spreads out evenly. It gives me better stability and control, even on uneven surfaces.

The Posi-Track system uses a flexible track. It also has an open-rail and internal positive drive-sprocket undercarriage. This design gives me more traction. Many ground contact points work with wide tracks. This spreads the machine’s weight. For example, an RT-135F has a low ground pressure of just 4.6 psi. This low pressure helps with flotation and traction. I can work on steep, slippery, and wet ground with better control. It also improves pushing capabilities. The wide, flexible track stays in contact with the ground more. This almost eliminates the chance of track derailment.

Why ASV RubberTracks Outperform Conventional Systems

I often think about what makes one machine better than another. For me, ASV machines consistently outperform others. They offer clear advantages in traction, efficiency, and how they treat the ground.

Superior Traction and Flotation

I often find myself working in tough conditions. That’s where these machines really shine. They give me amazing traction and flotation. This means I can grip the ground better, even on slippery slopes. The machine also stays on top of soft ground instead of sinking.

I remember Buck Storlie, an ASV product manager, talking about their turf tracks. He said landscapers often keep them on all the time. They work so well, especially when the ground is dry. He even mentioned a field test. ASV turf tracks did 30 turns without any damage. Another brand’s tracks dug deep ruts, 2-3 inches into the soil. That’s a big difference!

ASV turf tracks prevent soil compaction. They do this by spreading the machine’s weight evenly. Their smooth design helps a lot. It has no treads that can dig in. This design works with the Posi-Track undercarriage. The Posi-Track system itself helps spread weight. It uses flexible tracks and many ground contact points. This means less damage to the topsoil and plant roots. I can work on delicate surfaces without worry.

Enhanced Speed and Efficiency

I also notice how fast and efficient these machines are. ASV machines move quickly around the job site. They also save me money on fuel.

ASV compact track loaders have a smart hydraulic system. It senses the load. This system makes the machine more efficient. It also uses less fuel. The system only gives the hydraulic pump the power it needs. It doesn’t run at full power all the time. This precise control really saves fuel. I see lower operational costs because of this fuel-efficient design. I get all the power I need without wasting fuel.

Minimized Ground Pressure

One of the biggest benefits I see is how little pressure ASV machines put on the ground. Low ground pressure is super important. It means the machine won’t damage the surface. It also helps me work in soft, wet areas.

The Posi-Track system helps a lot here. It uses wide tracks and many contact points. This spreads the machine’s weight over a large area. For example, an RT-135F has a ground pressure of only 4.6 psi. That’s really low! This low pressure helps the machine float over soft ground. It also gives me better traction. I can work on steep or muddy ground with more control. The wide, flexible track stays in contact with the ground. This almost stops the track from derailing. It also protects the ground I’m working on.

Real-World Benefits of ASV Tracks

I have seen firsthand how ASV machines make a difference on the job. They offer practical advantages that impact my daily work.

Performance in Challenging Terrain

I often work in tough spots, and ASV tracks truly shine there. They give me exceptional efficiency and performance across many applications. I can use them in dirt, turf, sand, mud, and snow. These tracks, built with fiber-reinforced industrial rubber compounds, excel in flotation and durability. They are ideal for most conditions. Bogie wheels significantly improve flotation, making ASV machines perform well in soft underfoot conditions. My ASV machine has more ground contact points than steel-embedded models. This leads to lower ground pressure and extra flotation on steep, slippery, and wet ground. This design gives me enhanced control on snow, ice, mud, and slush.

ASV Tracks have an all-terrain, all-season tread pattern. It provides superior traction in mud, snow, gravel, and sand. This design includes a self-cleaning mechanism. It expels debris, preventing clogging and maintaining grip. The wider footprint of ASV Tracks also reduces ground pressure. This prevents sinking in soft soil and minimizes soil compaction. The Posi-Track system distributes weight evenly over a larger area. It uses more wheels per track than other brands. This further reduces ground pressure. For instance, my ASV RT-65 model can achieve ground pressure as low as 4.2 psi. This makes it suitable for delicate environments like wetlands.

Increased Operator Comfort

I really appreciate the comfort ASV machines offer. The fully suspended frame is crucial for absorbing impacts and vibrations. This gives me a smoother ride. The rubber-on-rubber contact design helps dampen bumps and jolts. It significantly reduces vibrations to me, the operator. I experience a dramatic reduction in vibrations. This enhances my comfort and alertness. Less bouncing means less fatigue. This allows me to concentrate better on tasks without discomfort. I think the suspension system is a game-changer for my well-being and productivity.

Reduced Operating Costs

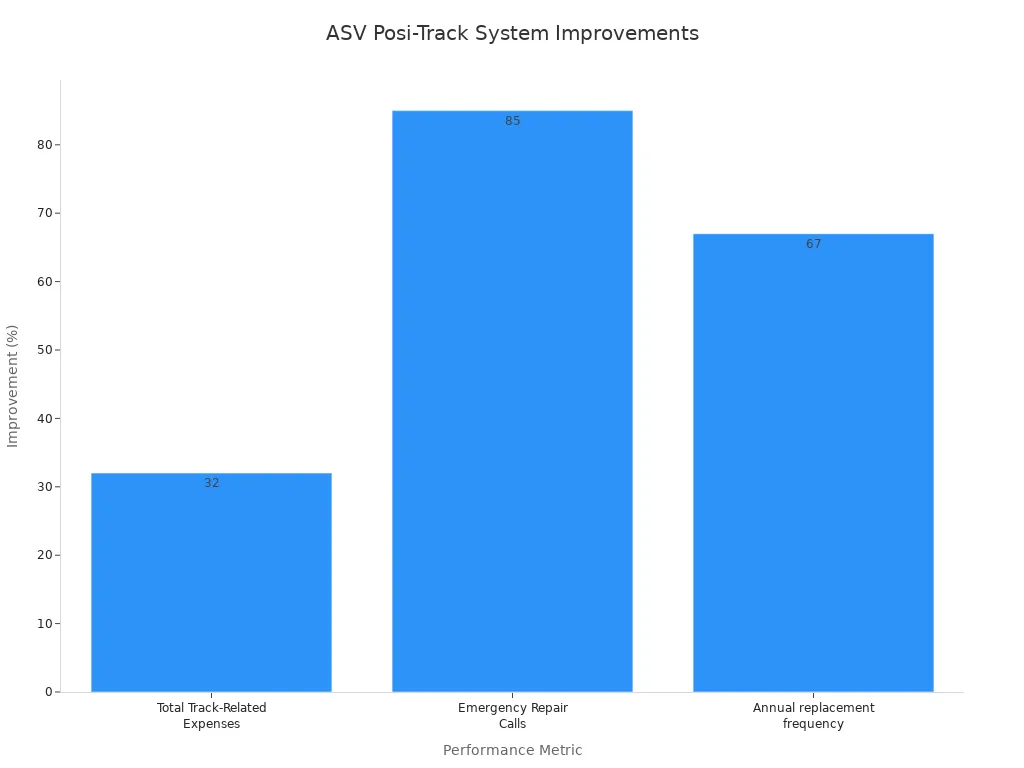

I also see significant savings with ASV tracks. My total track-related expenses have gone down. Emergency repair calls have decreased a lot. I used to replace tracks 2-3 times a year. Now, it’s usually just once.

| Performance Metric | ASV Posi-Track System Improvement |

|---|---|

| Total Track-Related Expenses | 32% reduction |

| Emergency Repair Calls | 85% decrease |

| Annual replacement frequency | drops from 2-3 times to once yearly |

Overall, I find ASV machines truly excel in tough conditions. They offer superior traction, comfort, and lower costs. Looking ahead, ASV is building even more powerful machines like the RT-135. They are also using strong Yanmar engines. This means even better performance and easier operation for me.

FAQ

What makes ASV rubber tracks so good on soft ground?

I find the Posi-Track system spreads weight widely. This gives me low ground pressure. It helps my machine float over soft surfaces instead of sinking.

How long do ASV tracks usually last?

I’ve seen ASV tracks last a long time. They use special rubber and strong materials. This gives me up to 1,000 extra hours compared to traditional tracks.

Can I use ASV tracks in all weather?

Yes, I can! Their all-terrain tread works great. It gives me superior traction in:

- Mud

- Snow

- Gravel

- Sand

It even cleans itself as I work.

Post time: Nov-06-2025